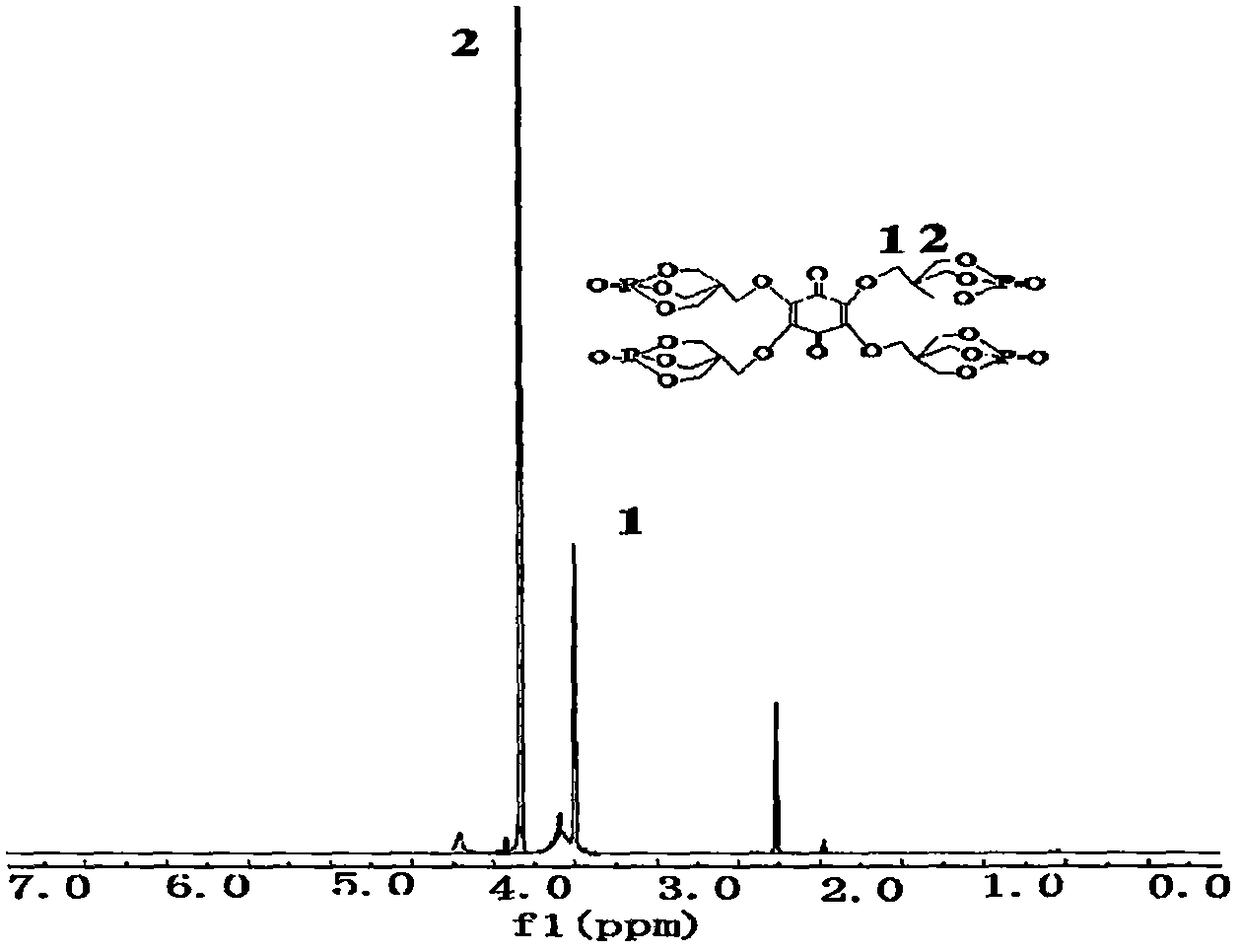

Colored flame retardant charring agent tetraPEPA oxy-p-benzoquinone compound and preparation method thereof

A technology of tetrachloro-p-benzoquinone and a char-forming agent, which is applied in the field of colored flame-retardant char-forming agents, can solve problems such as threats to life and property, and achieve the effects of less investment in equipment, simple preparation methods, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 In a 250ml three-necked flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, 80ml of dioxane solvent was added, 2.46g (0.01mol) of tetrachloro-p-benzoquinone was added, and 8.08g of PEPA sodium salt ( 0.04mol), heat up to 100℃ and keep for 6h, suction and filter to remove sodium chloride, the filtrate is cooled and crystallized, filtered, and dried to obtain reddish brown powder colored flame retardant char-forming agent tetra-PEPA oxy-p-benzoquinone, the yield is 85.1%, initial decomposition temperature: 350±5°C.

Embodiment 2

[0025] Example 2 In a 250ml three-necked flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, 70ml of dioxane solvent was added, 2.46g (0.01mol) of tetrachloro-p-benzoquinone was added, and 8.48g of PEPA sodium salt ( 0.042mol), heat up to 100°C and keep for 6h, suction filter to remove sodium chloride, the filtrate is cooled and crystallized, filtered, and dried to obtain reddish brown powder colored flame retardant char-forming agent tetra-PEPA oxy-p-benzoquinone, the yield is 87.9%, initial decomposition temperature: 350±5°C.

Embodiment 3

[0026] Example 3 In a 250ml three-necked flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, 70ml of ethylene glycol diethyl ether solvent was added, 2.46g (0.01mol) of tetrachloro-p-benzoquinone was added, and 8.89g of PEPA sodium salt was added (0.044mol), heat up to 120°C for 7h to keep the temperature, suction filter to remove sodium chloride, the filtrate is cooled and crystallized, filtered and dried to obtain reddish brown powder colored flame-retardant char-forming agent tetra-PEPA oxy-p-benzoquinone, yield It is 89.2%, initial decomposition temperature: 350±5°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com