Method for producing ecological organic fertilizer by anaerobic fermentation and aerobic fermentation

An organic fertilizer and ecological technology, which is applied in the field of anaerobic and aerobic fermentation to produce ecological organic fertilizer, can solve the problems of hindering the reproduction ability of aerobic bacteria and failing to exert their effects, and achieves increased absorption, enhanced enzyme activity, and promoted root development. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

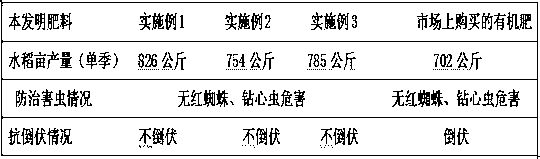

Examples

Embodiment 1

[0096] Ecological organic fertilizer, including the following raw materials by weight: 300 parts of sugarcane filter mud, 80 parts of plant ash, 15 parts of sugar cane molasses, 60 parts of calcium magnesium phosphate fertilizer, 220 parts of rice bran, 180 parts of peat, 40 parts of potassium fulvic acid, biological 3 parts of inoculum, 0.1 part of star anise residue; plant ash is burnt from wormwood; micro-fertilizer is a compound containing manganese, iron, zinc, boron, copper and molybdenum soluble in water, manganese sulfate, ferrous sulfate, sulfuric acid Zinc, sodium tetraborate, copper sulfate, ammonium molybdate, the weight ratio of elements is 5:2:1:0.5:0.1:0.01;

[0097] Screening of Bacillus amyloliquefaciens strains:

[0098] (A) Stack the filter mud of sugarcane or put it in an open cement pool, then spray with water to make the water content 50%, stack it for 20 days, stir it every day to make it fully in contact with the air, and wait until the filter mud of sugarca...

Embodiment 2

[0131] Biological anaerobic organic fertilizer, made of the following raw materials by weight: 350 parts of sugarcane filter mud, 100 parts of plant ash, 20 parts of sugar cane molasses, 65 parts of calcium magnesium phosphate fertilizer, 240 parts of rice bran, 200 parts of peat, potassium fulvic acid 45 parts, 5 parts of biological agent, 0.3 parts of star anise residue; plant ash is burnt from eucalyptus branches; micro-fertilizer is a compound containing manganese, iron, zinc, boron, copper and molybdenum elements soluble in water, manganese sulfate, sulfuric acid Ferrous, zinc sulfate, sodium tetraborate, copper sulfate, ammonium molybdate, the element weight ratio is 5:2:1:0.5:0.1:0.01;

[0132] Screening of Bacillus amyloliquefaciens strains:

[0133] (A) Stack the filter mud of sugarcane or put it in an open cement pool, and then spray it with water to make the water content 60%, stack it for 25 days, stir it every day to make it fully in contact with the air, and wait for ...

Embodiment 3

[0166] Biological anaerobic organic fertilizer, made of the following raw materials by weight: 370 parts of sugarcane filter mud, 110 parts of plant ash, 25 parts of sugar cane molasses, 67 parts of calcium magnesium phosphate fertilizer, 260 parts of rice bran, 210 parts of peat, potassium fulvic acid 47 parts, 7 parts of biological agents, 0.4 parts of star anise residue; plant ash is burnt from camphor tree branches; micro-fertilizer is a compound containing manganese, iron, zinc, boron, copper and molybdenum elements soluble in water, manganese sulfate, sulfuric acid Ferrous, zinc sulfate, sodium tetraborate, copper sulfate, ammonium molybdate, the element weight ratio is 5:2:1:0.5:0.1:0.01;

[0167] Screening of Bacillus amyloliquefaciens strains:

[0168] (A) Stack the filter mud of sugarcane or put it in an open cement pool, and then spray it with water to make the water content 55%, stack it for 30 days, stir it every day to make it fully in contact with the air, and wait u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com