Preparation method of light-weight mortar for ground pad layerfloor cushion

A technology of ground cushion and light sand, applied in the field of ground cushion, can solve the problems of insufficient properties and low completion of the preparation method, and achieve the effects of reducing self-weight, ensuring health and safety, and stable physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

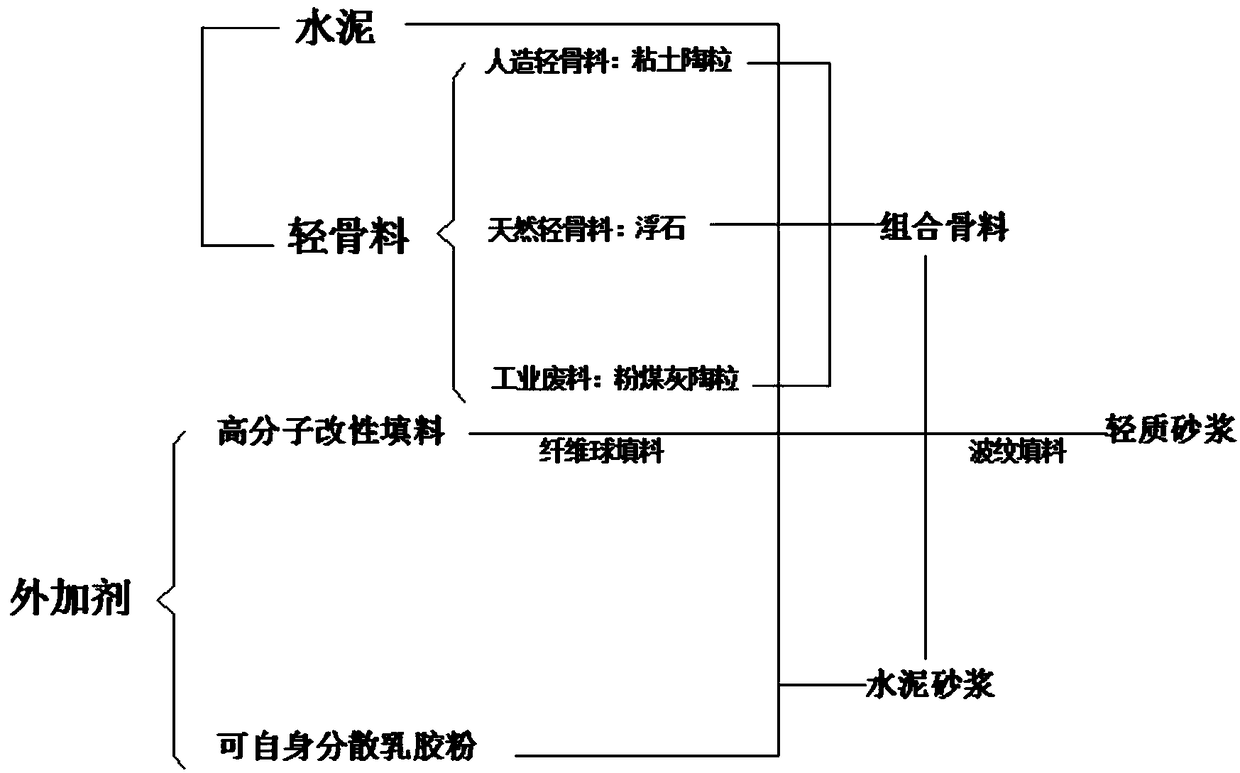

[0019] refer to figure 1 , a preparation method of light mortar for ground cushion, comprising the following steps:

[0020] S1: Cement mortar preparation: Weigh the raw material cement, sand and some admixtures. The admixtures are put into the renewable disperse latex powder. Put the above raw materials into the conical double-helix mixer according to the ratio of 3:9:1 and mix evenly , the stirring time is 20-35 minutes, and the cement mortar is obtained after stirring;

[0021] S2: Filling of lightweight aggregate and admixture: prepare lightweight mortar raw materials according to the ratio of 25-30 parts of lightweight aggregate, 15-25 parts of polymer modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com