A kind of cementitious material and its application

A technology of cementitious materials and raw materials, applied in cement production and other directions, can solve the problems of subsidence of underground goafs, cracking of cemented backfills, etc., and achieve the effects of no reduction in compressive strength, low price, good environmental benefits and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

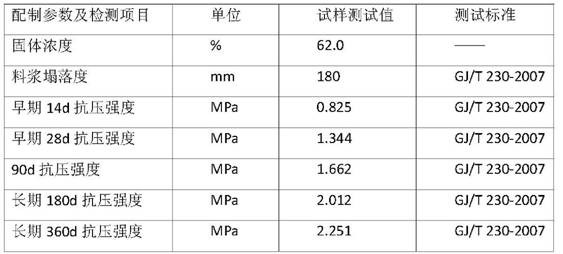

Embodiment 1

[0016] A cementitious material, made of the following raw materials in parts by weight: 0.1 part of water glass, 0.1 part of carbonate, 1 part of activated magnesium oxide and 81 parts of granulated blast furnace slag powder, the modulus of the water glass is 1.2 , the active magnesium oxide is made of magnesite calcined and ground at 600°C, with a particle size of 10 µm, and the granulated blast furnace slag powder is S105.

[0017] An application of the cementitious material in the cemented filling body of sulfide-containing mine tailings consists of the following steps: mixing the cementitious material, sulfide-containing mine tailings and water evenly, wherein the cementitious material accounts for the total solid mass 3%.

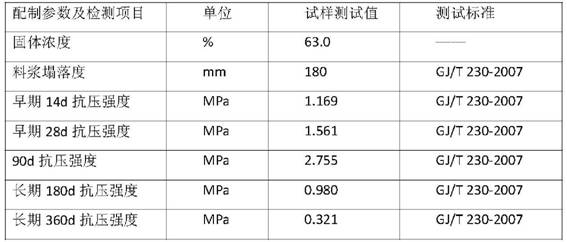

Embodiment 2

[0019] A cementitious material, made of the following raw materials in parts by weight: 1.05 parts of water glass, 1.05 parts of carbonate, 8 parts of active magnesium oxide and 90 parts of granulated blast furnace slag powder, the modulus of the water glass is 1.35 , the active magnesium oxide is calcined and ground at 800°C by magnesite, with a particle size of 45µm, and the granulated blast furnace slag powder is a mixture of S105, S95 and S75.

[0020] An application of the cementitious material in the cemented filling body of sulfide-containing mine tailings consists of the following steps: mixing the cementitious material, sulfide-containing mine tailings and water evenly, wherein the cementitious material accounts for the total solid mass 11.5%.

Embodiment 3

[0022] A cementitious material, made of the following raw materials in parts by weight: 2 parts of water glass, 2 parts of carbonate, 15 parts of active magnesium oxide and 99 parts of granulated blast furnace slag powder, the modulus of the water glass is 1.5 , the active magnesium oxide is made of magnesite calcined and ground at 1000°C, with a particle size of 80µm, and the granulated blast furnace slag powder is S75.

[0023] An application of the cementitious material in the cemented filling body of sulfide-containing mine tailings consists of the following steps: mixing the cementitious material, sulfide-containing mine tailings and water evenly, wherein the cementitious material accounts for the total solid mass 20% of.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com