A kind of preparation method and product of spherical metal-based nano-ceramic composite material for three-dimensional printing

A technology of nano-ceramics and composite materials, applied in the field of materials, can solve problems such as easy aggregation of nano-ceramic particles, local stress concentration of nanoparticles, and limited material adaptability, so as to ensure uniform particle size, improve thermal conductivity, and increase productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

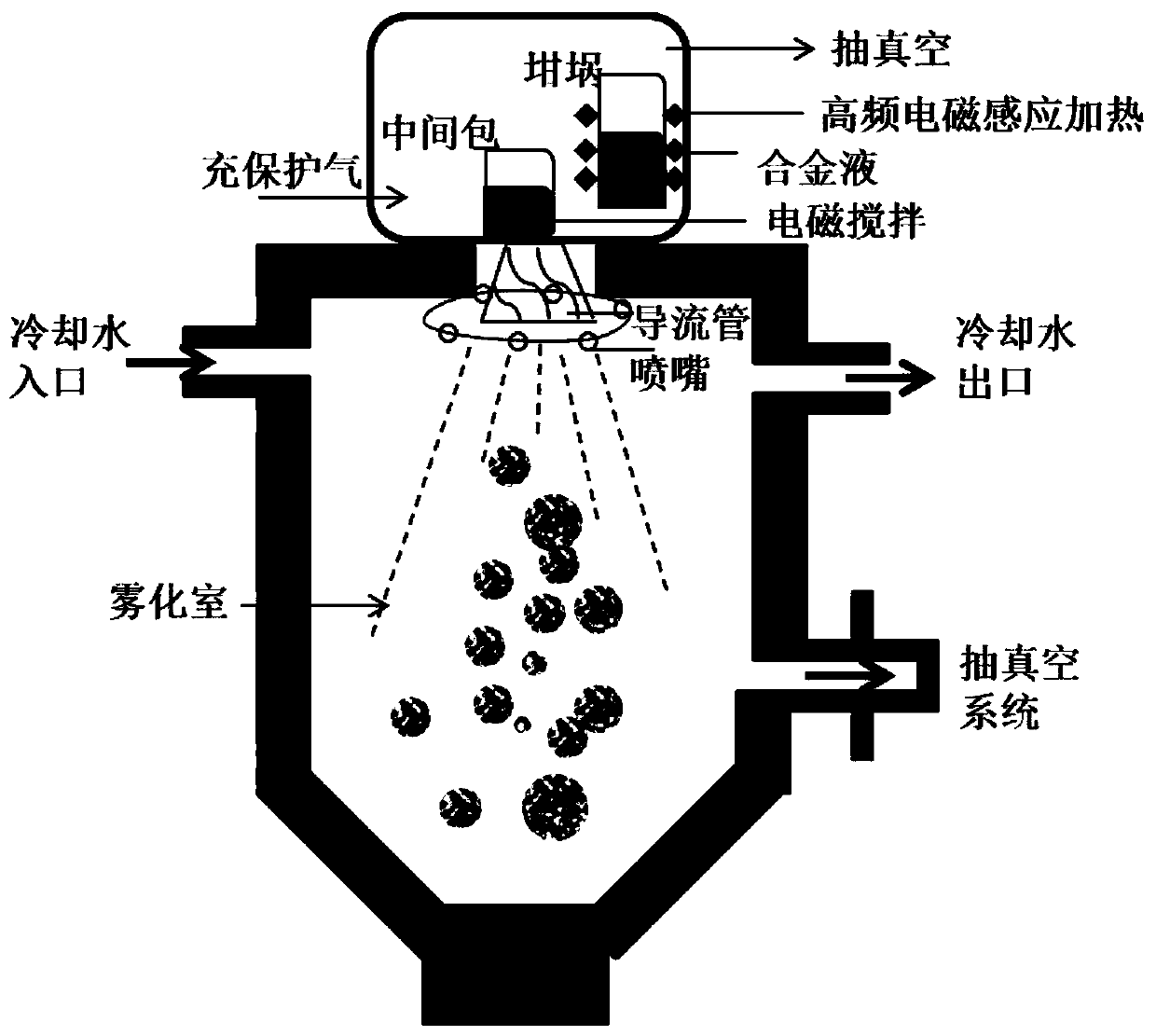

[0032] refer to figure 1 , the preparation of spherical metal-based nano-ceramic composites for three-dimensional printing includes the following steps:

[0033] (1) Add the aluminum alloy to the crucible of the high-frequency electromagnetic induction furnace, and vacuumize the crucible so that the vacuum degree in the crucible is 4.0×10 -3 Pa, and then filled with helium, the pressure of the helium is 0.3MPa, and the induction current with an intensity of 75A is adjusted to heat, so that the aluminum alloy is melted to form a melt, and the temperature of the melt is controlled at 30°C higher than the melting point of the aluminum alloy.

[0034] (2) Pour the melt obtained in step 1) into a tundish, and electromagnetically stir for 30 minutes at a speed of 150 r / min to remove impurities in the melt and homogenize it to obtain molten metal;

[0035] (3) Pass the molten metal obtained in step (2) through the pressure swirl guide tube with a spiral structure to form a rotating ...

Embodiment 2

[0038] refer to figure 1 , the preparation of spherical metal-based nano-ceramic composites for three-dimensional printing includes the following steps:

[0039] (1) Add the titanium alloy into the crucible of the high-frequency electromagnetic induction furnace, and vacuumize the crucible so that the vacuum degree in the crucible is 6.0×10 -3 Pa, and then filled with nitrogen gas, the pressure of the nitrogen gas is 0.2MPa, and the induction current with an intensity of 100A is adjusted to heat, so that the titanium alloy is melted to form a melt, and the temperature of the melt is controlled at 60°C higher than the melting point of the titanium alloy;

[0040] (2) Pour the melt obtained in step 1) into a tundish, and electromagnetically stir for 25 minutes at a speed of 100 r / min to remove impurities in the melt and homogenize it to obtain molten metal;

[0041] (3) Pass the molten metal obtained in step (2) through the pressure swirl guide tube with a spiral structure to f...

Embodiment 3

[0043] refer to figure 1 , the preparation of spherical metal-based nano-ceramic composites for three-dimensional printing includes the following steps:

[0044] (1) Add the iron-carbon alloy to the crucible of the high-frequency electromagnetic induction furnace, and vacuumize the crucible so that the vacuum degree in the crucible is 5.0×10 -3 Pa, then filled with argon gas, the pressure of the argon gas is 0.1MPa, and the induction current with a control intensity of 50A is heated to melt the iron-carbon alloy to form a melt, and the temperature of the melt is controlled at 100°C higher than the melting point of the iron-carbon alloy ;

[0045] (2) Pour the melt obtained in step 1) into a tundish, and electromagnetically stir for 15 minutes at a speed of 200 r / min to remove impurities in the melt and homogenize it to obtain molten metal;

[0046] (3) Pass the molten metal obtained in step (2) through the pressure swirl guide tube with a spiral structure to form a rotating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com