A kind of organic waste gas adsorption recycling equipment

A technology of adsorption recovery and organic waste gas, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low recovery rate of organic waste gas, leakage of organic gas, low purity of recovered organic matter, etc., and achieve the convenience of recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

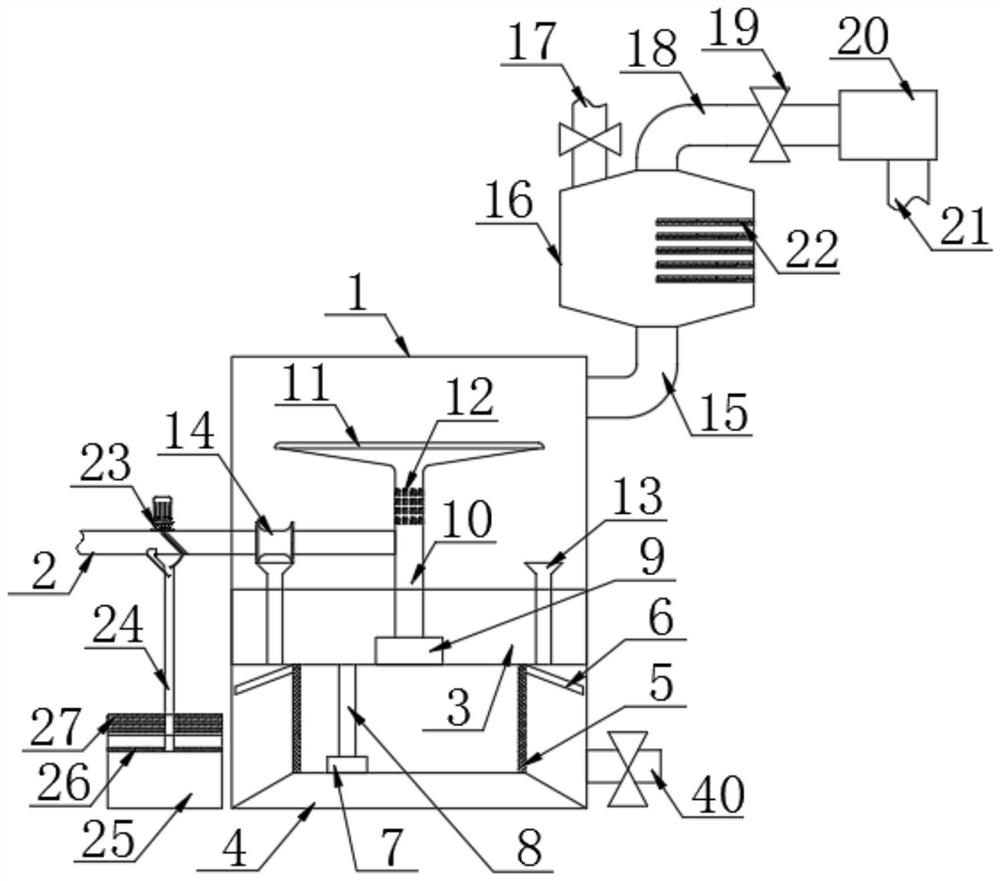

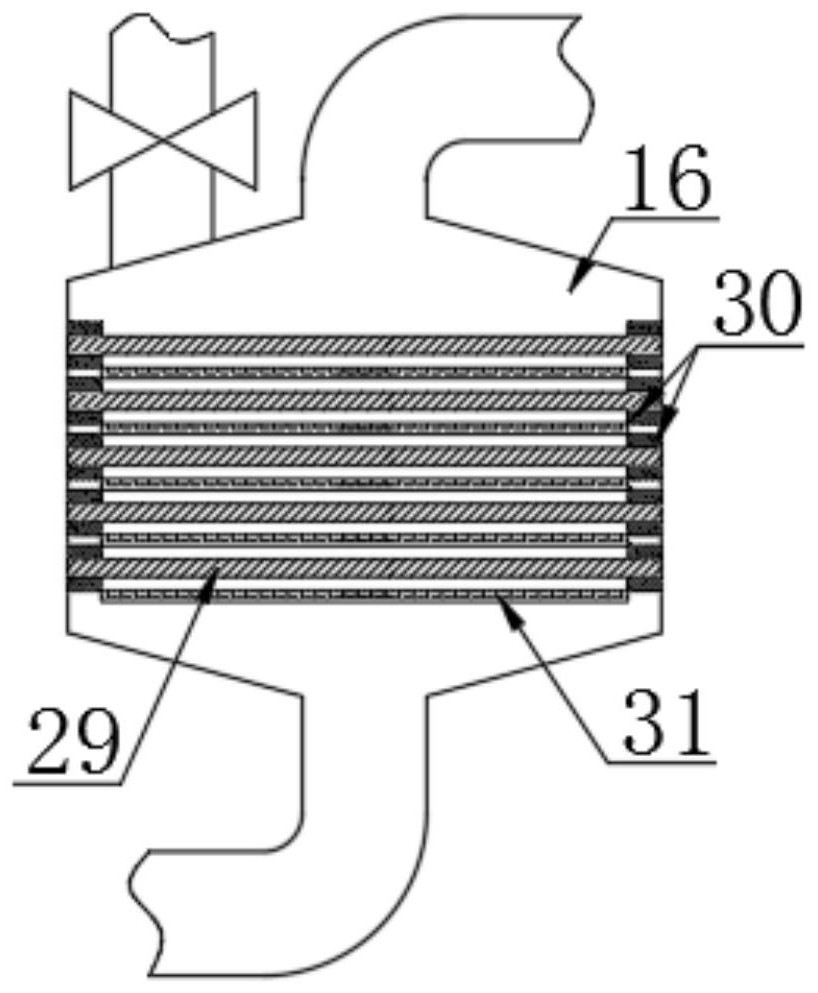

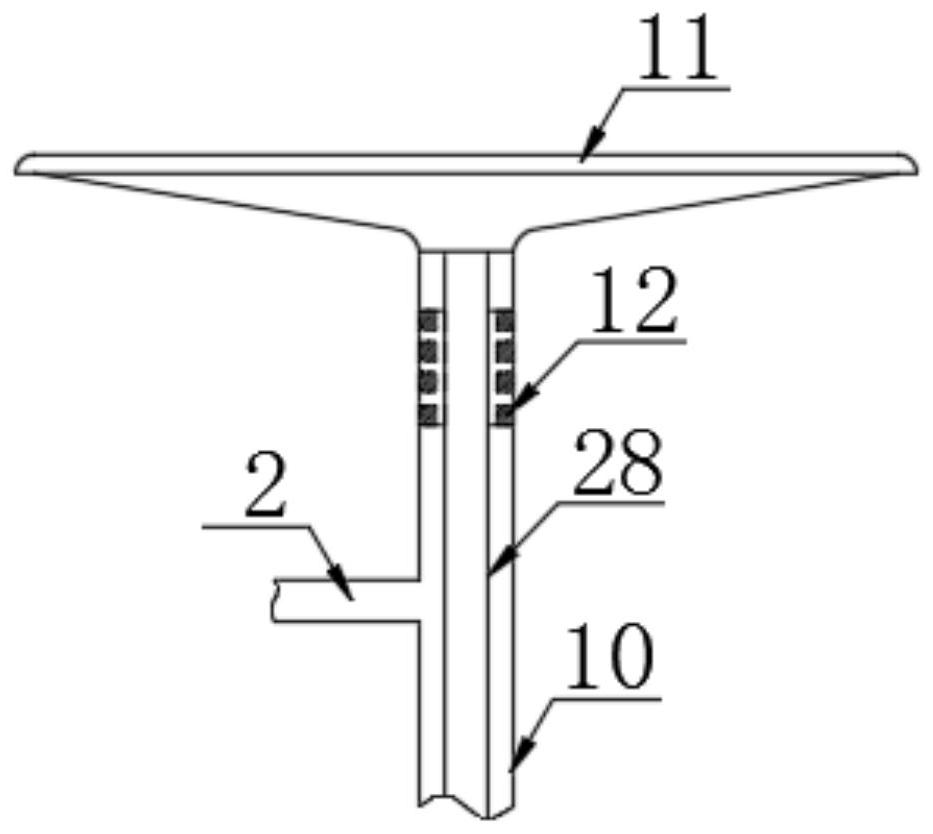

[0028] The present invention provides such Figure 1-6 The shown organic waste gas adsorption and recycling equipment includes a spray tower 1, an air inlet pipe 2 is connected to one side of the spray tower 1, a water tank 3 is arranged in the middle of the inner cavity of the spray tower 1, and the water tank 3 A base 4 is provided at the bottom, an isolation filter 5 is vertically provided between the base 4 and the water tank 3, a first water pump 7 is provided on the top of the base 4, and a circulating water pipe is connected to the end of the first water pump 7 8. The circulating water pipe 8 communicates with the water tank 3, and the bottom of the water tank 3 is provided with a second water pump 9, and the end of the second water pump 9 is connected with a water delivery pipe 28, and the end of the water delivery pipe 28 is connected with a Water tray 11, the outside of the water delivery pipe 28 is provided with an air guide pipe 10, the surface of the air guide pip...

Embodiment 2

[0036] Further, in the technical solution of Example 1, the bottom of the inner cavity of the water tank 3 is vertically provided with a leaking groove plate 13, and the bottom end of the water leakage groove plate 13 runs through the bottom plate of the water tank 3 and is provided with a flaring groove at the top. The flaring groove is annular in shape, and the outer diameter of the flaring groove is greater than the maximum diameter of the water tray 11, while the inner diameter of the flaring groove is smaller than the maximum diameter of the water tray 11, so that the water overflowing from the water tray 11 can flow into the drain. In the water tank plate 13, avoid falling into the clean water area in the water tank 3 and pollute the clean water, and can prevent the dust suspension mixed therein from causing blockage when the second water pump 9 sucks water.

[0037] Further, in the technical solution of Embodiment 1, a sleeve 14 is fixedly sleeved on the inlet pipe 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com