Preparation method of primary-taste modified rice fresh keeping agent material

A preservative and modification technology, which is applied in the field of preparation of original flavor modified rice preservative materials, can solve the problems of oxidative decomposition, residual odor, affecting rice storage quality and use effect, etc., achieve stable release performance and long-lasting performance, and improve The effect of long-lasting anti-oxidation performance and excellent sustained-release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

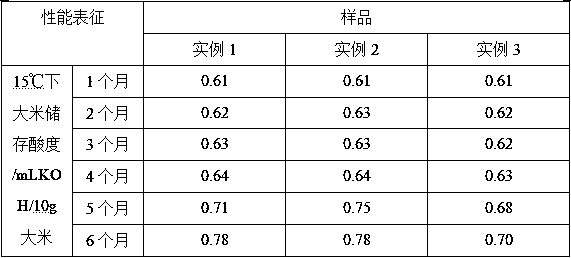

Examples

Embodiment Construction

[0017] Take the rice husk, wash it, dry it, crush it through a 200-mesh sieve, collect the sieved particles and put them in a muffle furnace, heat up to 450-500°C at a rate of 8°C / min, heat-preserve, calcinate and carbonize for 45-60min, and let stand to cool to room temperature and collect carbonized particles, weigh 45 to 50 parts of deionized water, 10 to 15 parts of potassium hydroxide and 15 to 20 parts of carbonized particles in a reaction kettle, stir and mix and place in 200 Ultrasonic disperse at ~300W for 10~15min, collect the mixed solution and place it in the reaction kettle, blow nitrogen to remove the air, then keep it warm at 800~900℃ for 1~2h, filter and collect the filter cake, rinse with deionized water for 3~ After 5 times, dry at 45-50°C for 6-8 hours to obtain adsorption-modified particles; then take defatted rice bran and add defatted rice bran to deionized water at a mass ratio of 1:10, stir and mix to obtain a mixed solution and place Heat in a water ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com