Device and method for collecting toxic gas in high-temperature decomposition of materials

A high-temperature decomposition and flue gas collection technology, which is applied in sampling devices, preparation of test samples, etc., can solve the problems of easy failure in the test process, incomplete gas absorption, and explosion of the combustion cylinder, and achieves simple structure, low cost, and avoidance of The effect of backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

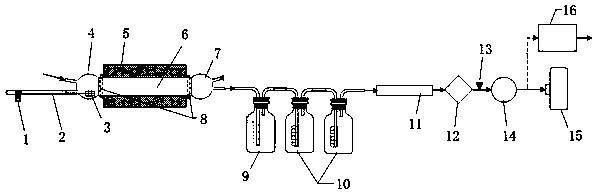

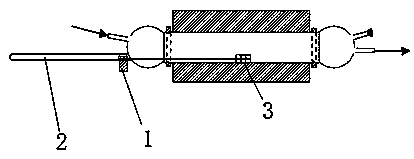

[0066] Preparation before the experiment: Take 1g of rubber sample, cut it into pieces below 1mm³, place the sample in the sample boat, put on the sample inlet epitaxial tube, fix it with a connecting ferrule, and connect all the flow paths with Teflon tubes; conventional gas Two absorption bottles are connected in series, and 700ml of 1mol / L NaOH absorption solution is added to the two gas absorption bottles; the drying tube is filled with anhydrous calcium chloride; the temperature of the tubular cracking furnace is raised to 600°C; the gas The flow path provides carrier gas, and the pressure is first adjusted to 0.1MPa.

[0067] Test process: The sample boat with the sample is pushed into the center of the quartz combustion cylinder through the sample push magnetic block; the pyrolysis toxic flue gas passes through the anti-suckback buffer bottle and the gas absorption bottle with the carrier gas, and the absorption liquid in the gas absorption bottle absorbs HCN , SO2, HCl...

experiment example 2

[0069] Preparation before the experiment: Take 1g of rubber sample, cut it into pieces below 1mm³, put the sample in the sample boat; connect all the flow paths with polytetrafluoroethylene tubes; 490ml 0.1mol / L NaOH and 10mlH 2 o 2 The composed absorption solution; the drying tube is filled with silica gel desiccant; the temperature of the tubular cracking furnace is raised to 600°C.

[0070] Test process: The air generator is purified and connected to the sample flow path from the other inlet of the double-port ball inlet joint; the sample boat with the sample is directly pushed into the quartz with a stainless steel bracket from one inlet of the double-port ball inlet joint. Immediately block the entrance with a plug after entering the combustion tube; the pyrolysis toxic flue gas passes through the anti-suckback buffer bottle and gas absorption bottle with the carrier gas, and the absorption liquid in the gas absorption bottle absorbs HCN, SO 2 , HCl, HF, HBr and other g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com