Coating for erosion resistance and cavitation suppression

A corrosion-resistant and cavitation-resistant technology, used in anti-corrosion coatings, anti-fouling/underwater coatings, polyurea/polyurethane coatings, etc. Mechanical properties, reduction of erosion phenomenon, effect of low surface energy of coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

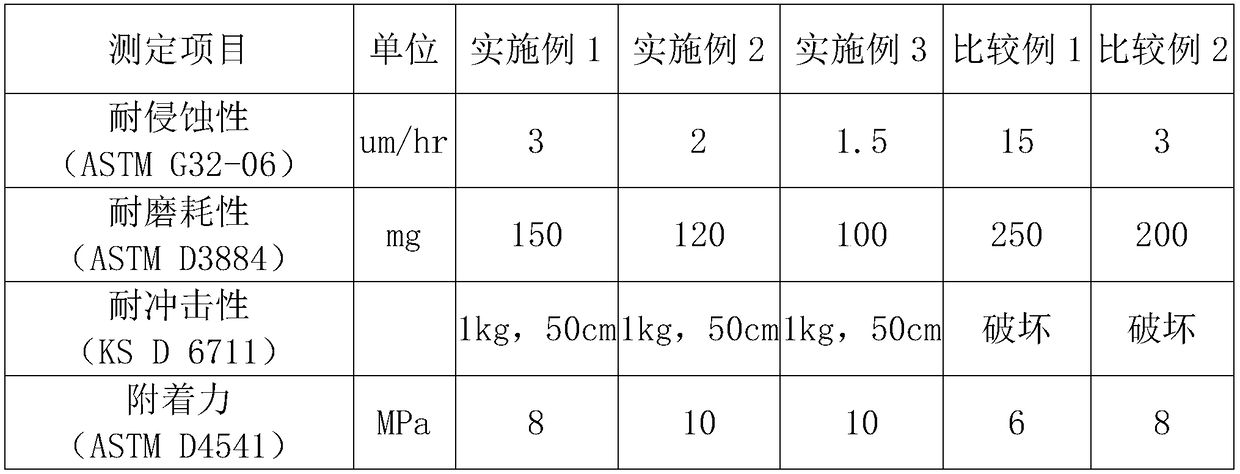

Examples

Embodiment 1

[0021] The coating for corrosion resistance and cavitation suppression includes an ultrafast curing agent solution and a modified silicon nanopowder solution, and the ultrafast curing agent solution and the modified silicon nanopowder solution are mixed at a volume ratio of 1:1;

[0022] Wherein, the ultra-fast curing agent solution is polyisocyanate with an NCO% content of 12%; the modified silicon nanopowder solution includes the following components in weight percent: polyoxypropylene diamine 33%, polyether triamine with a molecular weight of 5000 9%, polyphenylene triamine 12%, modified amino silicone resin 15%, modified fluororesin 5%, adhesion promoter 1%, pigment 2% and nanometer powder 23%.

[0023] Further, the adhesion promoter is β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane.

[0024] Further, the nanopowder is titanium.

Embodiment 2

[0026] The coating for corrosion resistance and cavitation suppression includes an ultrafast curing agent solution and a modified silicon nanopowder solution, and the ultrafast curing agent solution and the modified silicon nanopowder solution are mixed at a volume ratio of 1:1;

[0027] Wherein, the ultra-fast curing agent solution is polyisocyanate with an NCO% content of 15%; the modified silicon nanopowder solution includes the following components in weight percent: polyoxypropylene diamine 33%, polyether triamine with a molecular weight of 5000 9%, polyphenylene triamine 12%, modified amino silicone resin 15%, modified fluororesin 5%, adhesion promoter 1%, pigment 2% and nanometer powder 23%.

[0028] Further, the adhesion promoter is β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane.

[0029] Further, the nanopowder is titanium.

Embodiment 3

[0031] The coating for corrosion resistance and cavitation suppression includes an ultrafast curing agent solution and a modified silicon nanopowder solution, and the ultrafast curing agent solution and the modified silicon nanopowder solution are mixed at a volume ratio of 1:1;

[0032] Wherein, the ultra-fast curing agent solution is a polyisocyanate with an NCO% content of 13.5%; the modified silicon nanopowder solution includes the following components in weight percent: 30% polyoxypropylene diamine, polyether triamine with a molecular weight of 5000 8%, polyphenylene triamine 10%, modified amino silicone resin 9%, modified fluororesin 3%, adhesion promoter 1%, pigment 2% and nano powder 35%.

[0033] Further, the adhesion promoter is β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane.

[0034] Further, the nanopowder is titanium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com