Graphene heavy anti-corrosion coating and preparation method thereof

A graphene and heavy-duty anti-corrosion technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as insufficient anti-corrosion performance, and achieve the effect of anti-corrosion performance improvement and efficient shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

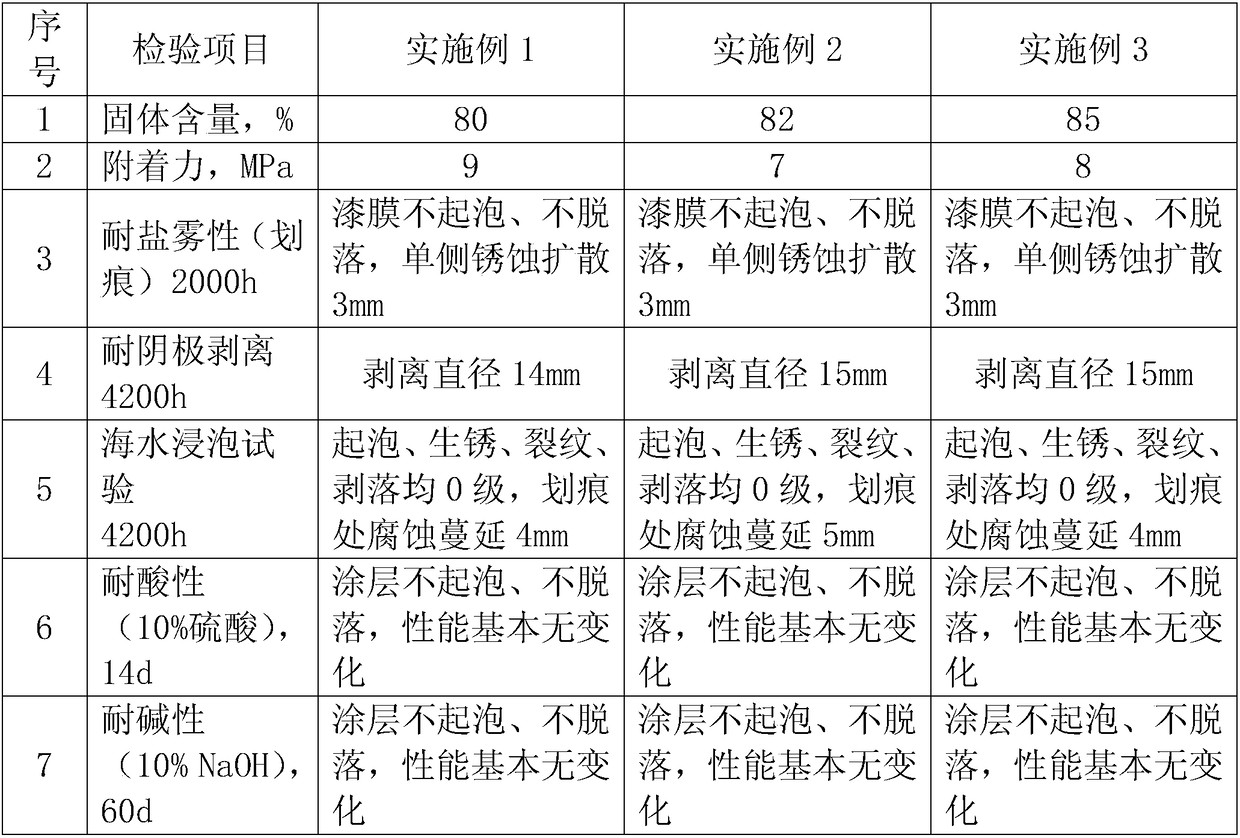

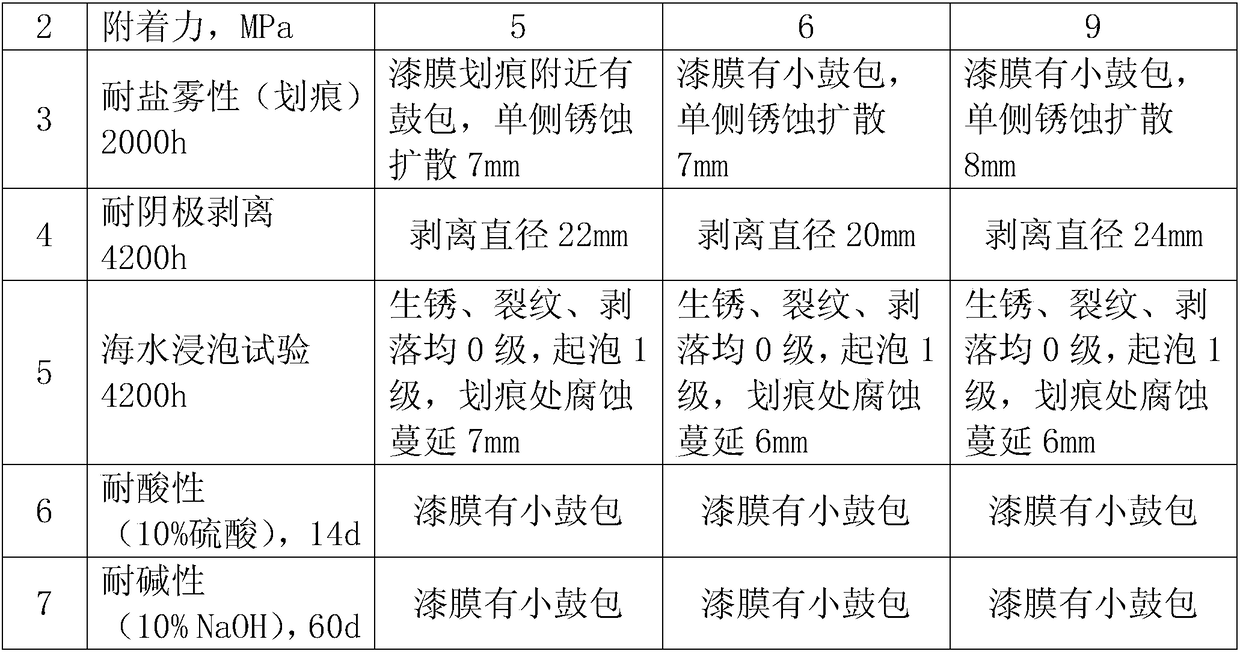

Examples

Embodiment 1

[0026] Preparation of self-synthesized polyurethane modified epoxy resin, hydroxyl-terminated polyether is selected from Shandong Bluestar Dongda Chemical Co., Ltd. product DL-2000D, diphenylmethane diisocyanate and E-51 epoxy resin according to the ratio of 1:2.2:5 The molar ratio is polymerized step by step, and the synthesis process is as follows: add all N220 to the reactor, vacuum dehydrate at 120°C for 2 hours; add all diphenylmethane diisocyanate, and add T-9 which accounts for 0.12‰ (weight ratio) of the total resin Catalyst continues to react 2h under high-speed stirring at 75 ℃; Add all E-51 epoxy resins, and the xylene that accounts for 30% of resin gross weight, react 2h under high-speed stirring at 75 ℃; Add and account for resin total amount 0.42‰ ( weight ratio) of the T-9 catalyst, continued to react for 2h under stirring at 75°C, and finally obtained a self-synthesized polyurethane modified epoxy resin with an epoxy equivalent of 642 and a solid content of 70%....

Embodiment 2

[0034] The self-synthesized polyurethane-modified epoxy resin prepared in Example 1 was adopted.

[0035] Component A of graphene heavy-duty anticorrosion coating (parts by weight): 13 parts of E-20 epoxy resin, 3 parts of self-synthesized polyurethane modified epoxy resin, 8 parts of xylene, 8 parts of n-butanol, 0.3 part of modified graphene , 43 parts of mica iron oxide ash, 13 parts of 809 anti-rust pigment, 8 parts of mica powder, 1.3 parts of titanium dioxide, 0.36 parts of wetting and dispersing agent TEGO 628, 0.04 parts of defoamer BYK-085, 2 parts of Bengel 434 organic bentonite.

[0036] Component B of graphene heavy-duty anti-corrosion coating (parts by weight): 60 parts of polyamide curing agent SY-H115, 10 parts of xylene, 8 parts of n-butanol, and 6 parts of accelerator DMP-30.

[0037] Graphene heavy-duty anti-corrosion coating is prepared according to the following steps:

[0038] First, add modified graphene and part of xylene into a high-speed stirring tank, ...

Embodiment 3

[0042] The self-synthesized polyurethane-modified epoxy resin prepared in Example 1 was adopted.

[0043] Component A of graphene heavy-duty anticorrosion coating (parts by weight): 10 parts of E-20 epoxy resin, 5 parts of self-synthesized polyurethane modified epoxy resin, 6 parts of xylene, 7.5 parts of n-butanol, 0.5 part of modified graphene , 50 parts of mica iron oxide red, 11 parts of 809 antirust pigment, 5.3 parts of mica powder, 1.2 parts of titanium dioxide, 0.47 parts of wetting and dispersing agent AFCONA-5066, 0.03 parts of defoamer TEGO Airex 9000, 3 parts of Bengel 434 organic bentonite.

[0044] Component B of graphene heavy-duty anti-corrosion coating (parts by weight): 55 parts of polyamide curing agent Versamid 115, 25 parts of xylene, 12 parts of n-butanol, and 8 parts of accelerator DMP-30.

[0045] Graphene heavy-duty anti-corrosion coating is prepared according to the following steps:

[0046] First, add the modified graphene and part of xylene into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com