Pressure storage type compressed gas foam extinguishing system

A compressed gas and foam fire extinguishing technology, which is applied in fire rescue and other fields, can solve the problems that the foam liquid cannot be fully dispersed and mixed, affects the overall operation of the fire extinguishing system, and the pressure of gas and liquid is unstable, and achieves wide coverage and easy operation. Convenience and quick fire extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

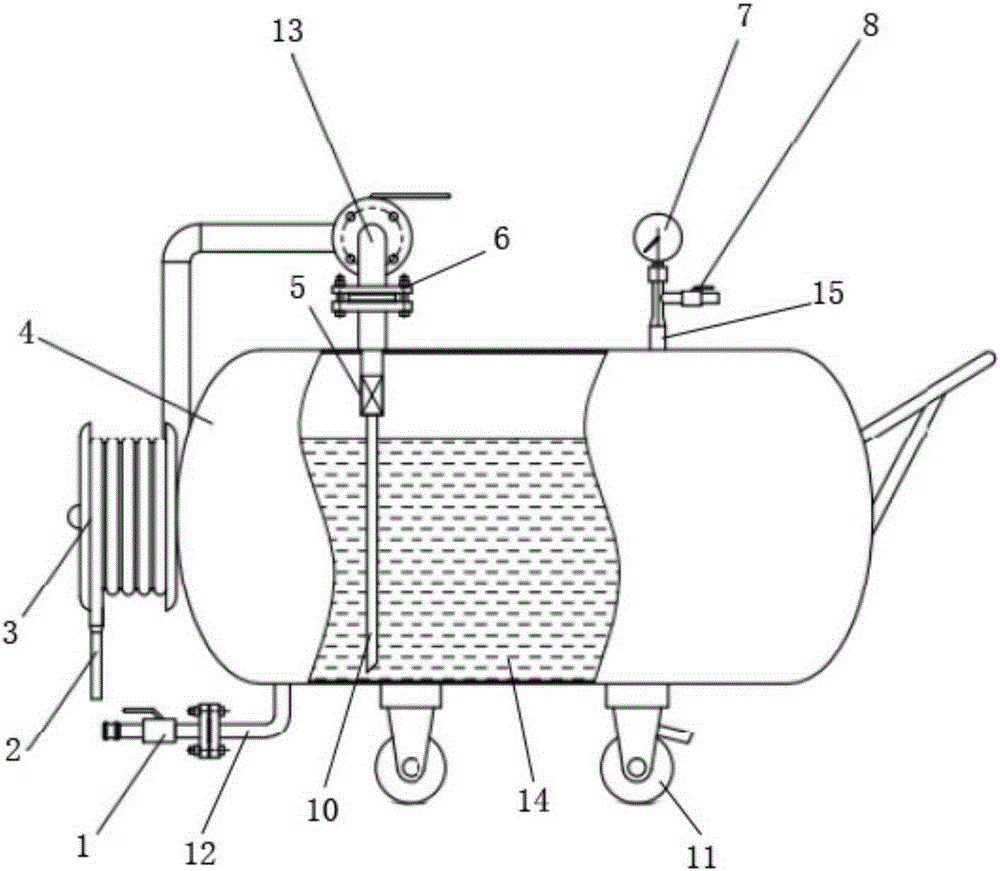

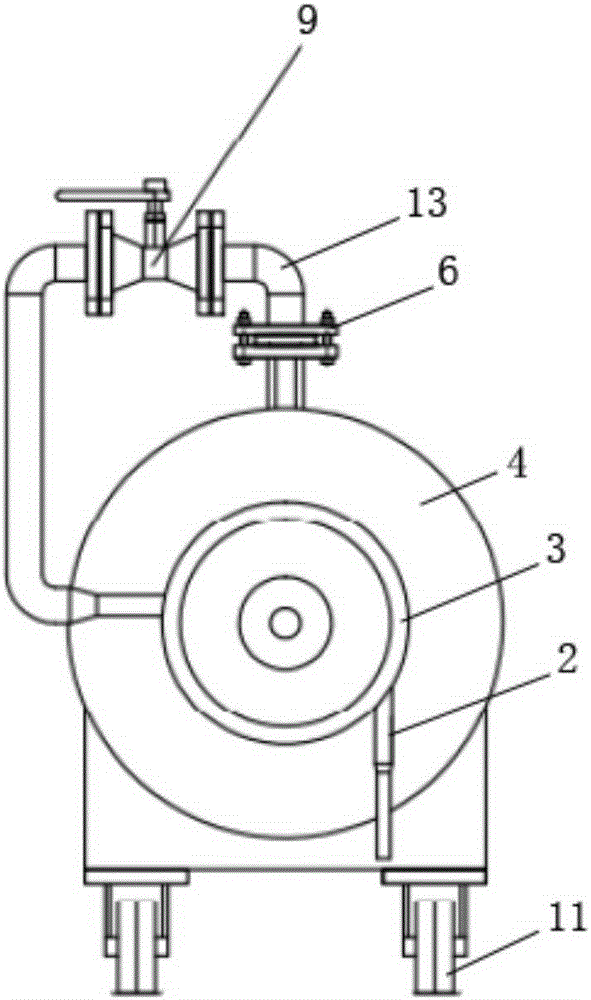

[0029] Such as figure 1 and figure 2 As shown, a pressure-storage compressed gas foam fire extinguishing system includes a pressure liquid storage tank 4 and a foam generator 5, and a walking wheel 11 is arranged under the pressure liquid storage tank 4, and the pressure liquid storage tank 4 is filled with a foam fire extinguishing agent Mixed liquid 14 and compressed gas, the top of the pressure storage tank 4 is provided with a liquid inlet pipe and a pressure gauge 7, the liquid inlet pipe 15 is provided with a flow control valve 8, the compressed gas is air, nitrogen or inert gas, the pressure storage The volume of liquid tank 4 is 10m 3 , the quality of filling the foam fire extinguishing agent mixture 14 is 5000kg, the volume of the foam fire extinguishing agent mixture 14 accounts for 50% of the volume of the pressure liquid storage tank 4, and the foam fire extinguishing agent mixture 14 is filled in the pressure liquid storage tank 4 The filling pressure is 1.2MPa...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, the only difference is that the quality of the foam fire extinguishing agent mixture 14 filled is 6000kg, and the volume of the foam fire extinguishing agent mixture 14 accounts for 60% of the volume of the pressure liquid storage tank 4. The filling pressure of the foam fire extinguishing agent mixture 14 filled in the pressure liquid storage tank 4 is 1.3MPa.

Embodiment 3

[0034] This embodiment is basically the same as Embodiment 1, the only difference is that the quality of the foam fire extinguishing agent mixture 14 filled is 7000kg, and the volume of the foam fire extinguishing agent mixture 14 accounts for 70% of the volume of the pressure liquid storage tank 4. The filling pressure of the foam fire extinguishing agent mixture 14 filled in the pressure liquid storage tank 4 is 1.5MPa.

[0035] The principles of embodiments 1 to 3 are the same. When fire extinguishing or coverage is required, the one-way outlet valve 9 is opened, and the foam fire extinguishing agent mixture 14 enters the foam generator 5 through the suction pipe 10, and the foam fire extinguishing agent mixture 14 passes through the liquid inlet. The mouth is sprayed onto the spoiler to form a mist, and the compressed gas enters the foam generator 5 through the air inlet, and fully collides with the mist droplets in the foam generator 5 to form energetic foam. The outlet v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com