Method for preparing Besifovir

A compound, methyl technology, applied in the field of new intermediates, can solve the problems of increasing experimental costs and expensive prices, and achieve the effects of reducing the difficulty of purification, increasing yield, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

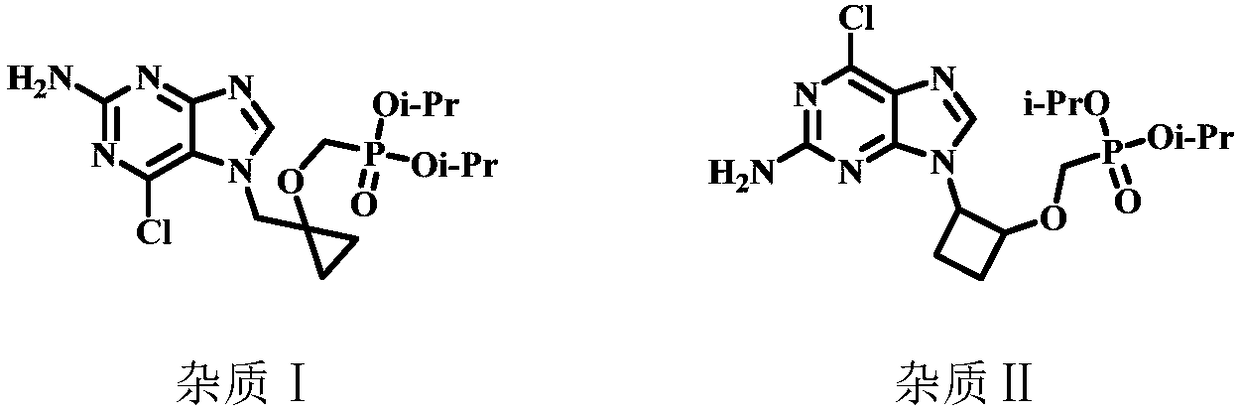

Problems solved by technology

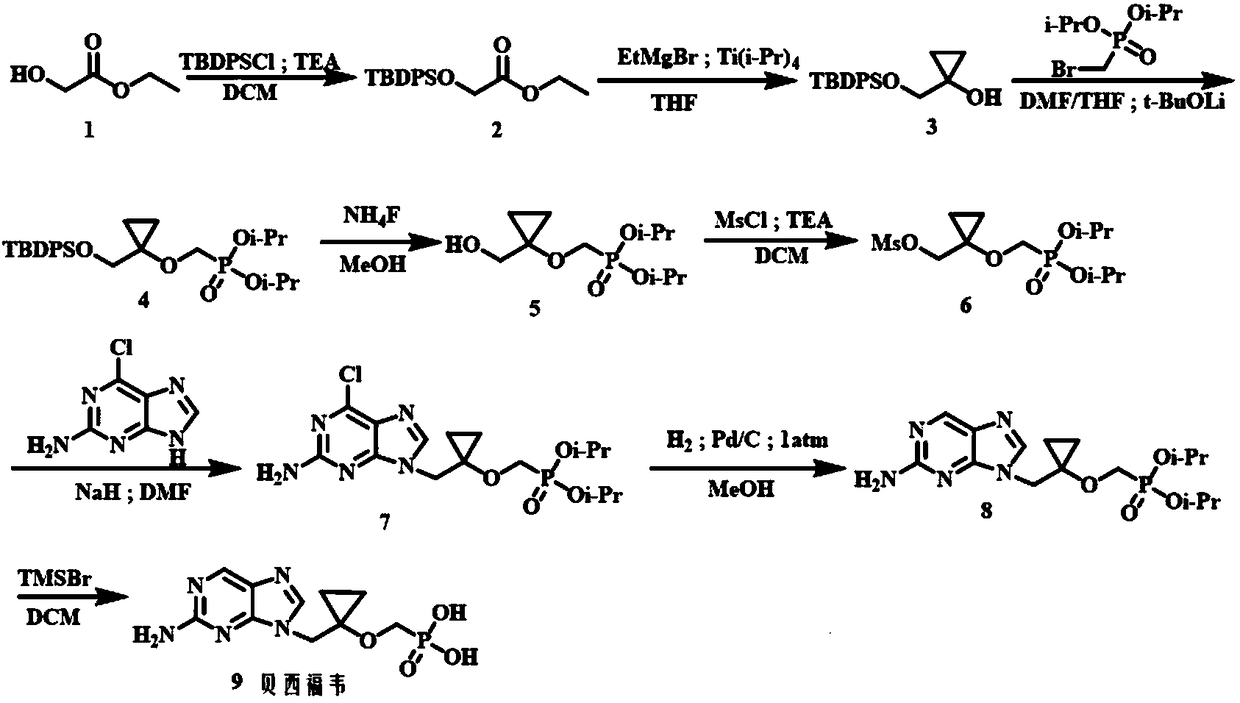

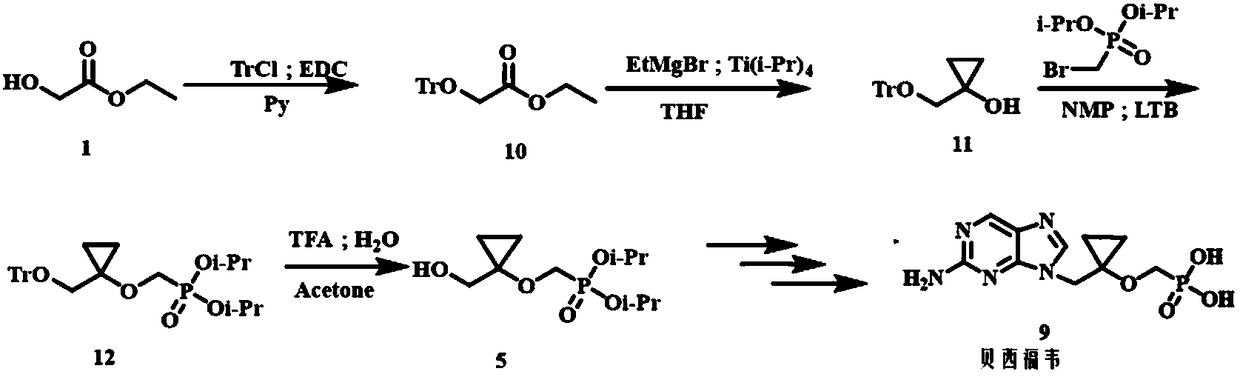

Method used

Image

Examples

Embodiment

[0049] Step 1: Preparation of 2-((tert-butyl(diphenyl)silyl)oxy)ethyl acetate (2):

[0050] 1 (100.0g, 960.52mmol) and imidazole (77.3g, 1.15mol) were dissolved in dichloromethane (1.5L), and tert-butyldiphenylchlorosilane was slowly added dropwise with a constant pressure dropping funnel under ice-cooling conditions (264.0 g, 960.52 mmol). After the dropwise addition was completed, it was transferred to room temperature for 16 h. Filtrate, wash the filtrate with 1.0mol / L hydrochloric acid solution (300ml×2), wash the dichloromethane layer with saturated sodium bicarbonate solution (100ml×2), dry over anhydrous sodium sulfate, and concentrate to give white transparent liquid 2 (297.7g ,91%). ESI-MS(m / z):365.1564[M+Na] + ; 1 H NMR (300MHz, CDCl3) δ: 7.87~7.76 (m, 4H), 7.47 (q, J = 5.4Hz, 6H), 4.35 (s, 2H), 4.22 (q, J = 7.1Hz, 2H), 1.28 (t,J=7.1Hz,3H),1.21(s,9H); 13 CNMR (75MHz, CDCl3) δ: 171.2, 135.7, 132.9, 130.0, 127.9, 62.4, 60.7, 26.8, 19.4, 14.2.

[0051] Step 2: Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com