Method for processing yak bones by biotechnology

A biotechnology, yak bone technology, applied in the field of extraction of biologically active substances, can solve problems such as inability to completely remove fat, difficulty in collagen purification, and no degreasing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

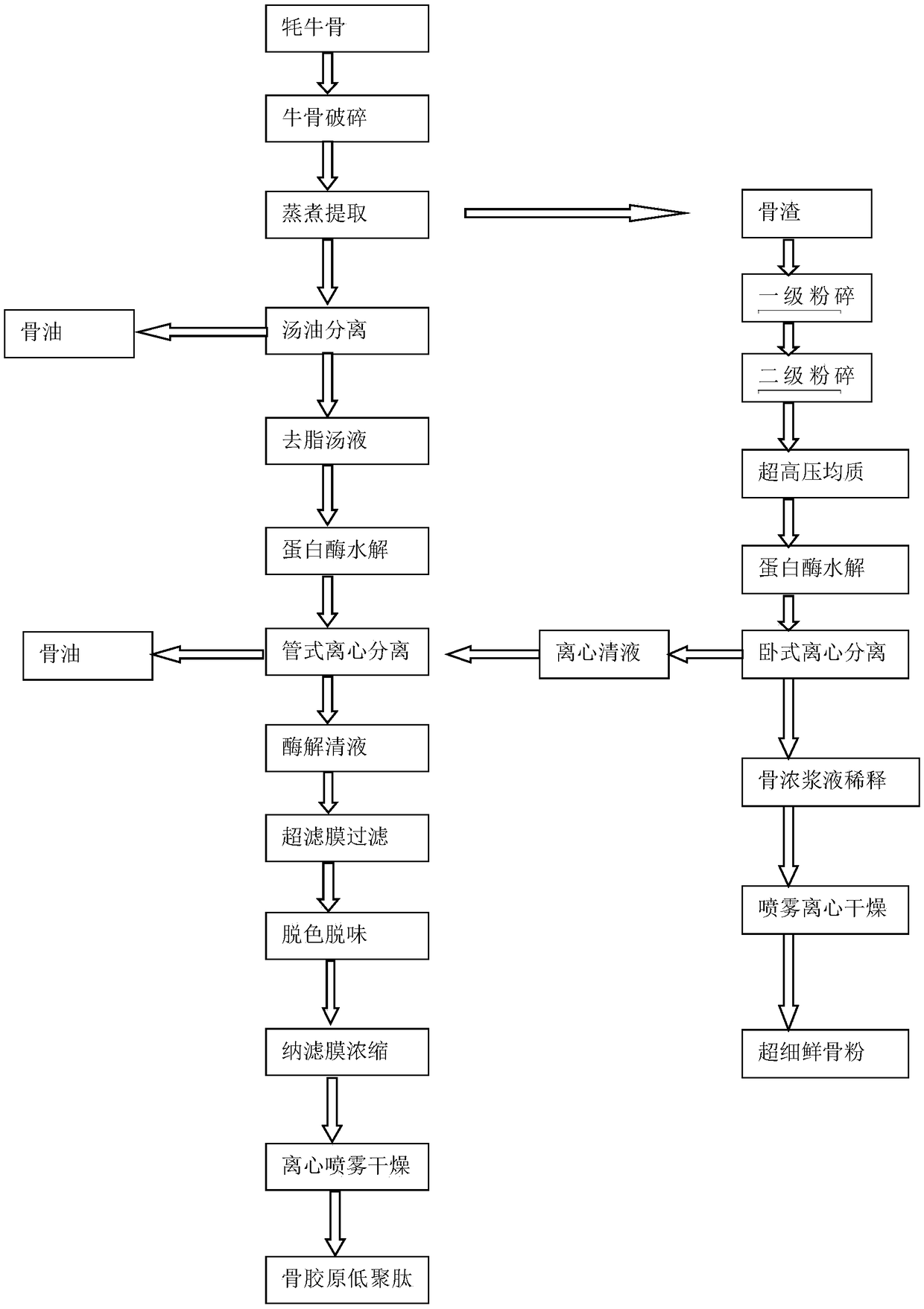

[0046] A method for processing yak bones through biotechnology, specifically comprising the following steps:

[0047] Step 1. Crushing the yak bone to 3cm-6cm, putting it into a cooking tank for high-temperature and high-pressure extraction to obtain oily bone broth and oily bone residue;

[0048] Step 2. The oil-containing bone broth obtained in step 1 is made into collagen oligopeptides, which includes the following steps in turn: soup oil separation, protease hydrolysis, tubular centrifugal separation, ultrafiltration membrane filtration, decolorization and deodorization, nanofiltration membrane concentration , centrifugal spray drying;

[0049] Step 3. The oily bone residue obtained in step 1 is made into superfine fresh bone powder, which includes the following steps in turn: primary crushing, secondary crushing, ultra-high pressure homogenization, protease hydrolysis, horizontal centrifugal separation, thick slurry dilution, centrifugation Spray dry.

[0050] Preferabl...

Embodiment 2

[0071] A method for processing yak bones through biotechnology, comprising the steps of:

[0072] Step 1. Crushing the yak bone to 3 cm, putting it into a cooking tank for high-temperature and high-pressure extraction to obtain oily bone broth and oily bone residue;

[0073] Step 2. The oil-containing bone broth obtained in step 1 is made into collagen oligopeptides, which include the following steps in turn: soup oil separation, protease hydrolysis, tubular centrifugal separation, ultrafiltration membrane filtration, decolorization and deodorization, nanofiltration membrane concentration , centrifugal spray drying;

[0074] Step 3. The oily bone residue obtained in step 1 is made into superfine fresh bone powder, which includes the following steps in turn: primary crushing, secondary crushing, ultra-high pressure homogenization, protease hydrolysis, horizontal centrifugal separation, thick slurry dilution, centrifugation Spray dry.

[0075] In said step one, the specific me...

Embodiment 3

[0097] A method for processing yak bones through biotechnology, comprising the steps of:

[0098] Step 1. Crushing the yak bone to 6 cm, putting it into a cooking tank for high-temperature and high-pressure extraction to obtain oily bone broth and oily bone residue;

[0099] Step 2. The oil-containing bone broth obtained in step 1 is made into collagen oligopeptides, which include the following steps in turn: soup oil separation, protease hydrolysis, tubular centrifugal separation, ultrafiltration membrane filtration, decolorization and deodorization, nanofiltration membrane concentration , centrifugal spray drying;

[0100] Step 3. The oily bone residue obtained in step 1 is made into superfine fresh bone powder, which includes the following steps in turn: primary crushing, secondary crushing, ultra-high pressure homogenization, protease hydrolysis, horizontal centrifugal separation, thick slurry dilution, centrifugation Spray dry.

[0101] In said step one, the specific me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com