Ceramic filter element of diatomite composite activated carbon as well as production method thereof

A technology of composite activated carbon and ceramic filter elements, applied in the field of filter elements, can solve the problems of weak acidity of effluent, achieve the effect of improving pH value, avoiding micropore shrinkage, and improving water turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

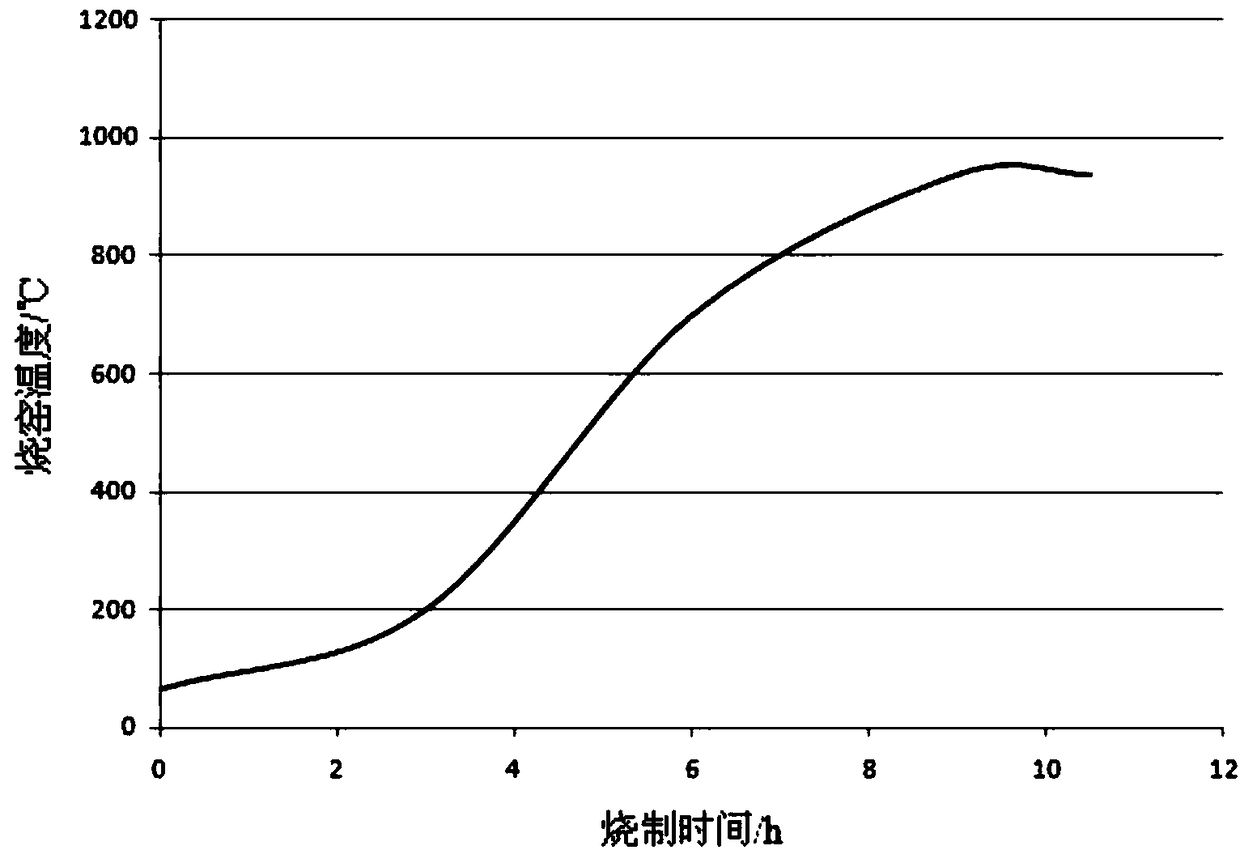

Image

Examples

Embodiment 1

[0049] (1) Add 80 parts of diatomite, 8 parts of activated carbon, 2 parts of calcite, 2 parts of clay powder, 2 parts of dolomite, 2 parts of swollen starch, and 0.5 part of chromium trioxide into a high-speed mixer for high-speed mixing of dry powder;

[0050] (2) Weigh 3 parts of polyvinyl alcohol, mix the alcohol and polyvinyl alcohol evenly according to the mass ratio of 1:1, add the high mixer to stir, then add water accounting for 0.35% of the total weight of the added ingredients, and stir at a high speed Uniform, forming a semi-dry powder;

[0051] (3) passing the semi-dry powder obtained in step (2) through a 40-mesh sieve to obtain semi-dry powder particles;

[0052] (4) Fill the semi-dry powder granules obtained in step (3) into the mold and obtain the filter element green body after semi-dry pressing molding, place the filter element green body in a box filled with powdered activated carbon, and seal the box with a lid, between the lid and the box Seal it with ce...

Embodiment 2

[0057] (1) Add 90 parts of diatomite, 15 parts of activated carbon, 3 parts of calcite, 3 parts of clay powder, 3 parts of dolomite, 3 parts of swollen starch, and 1.0 part of chromium trioxide into a high-speed mixer for high-speed mixing of dry powder;

[0058] (2) Weigh 5 parts of polyvinyl alcohol, mix the alcohol and polyvinyl alcohol evenly according to the mass ratio of 1:1, add the high mixer to stir, then add water accounting for 0.45% of the total weight of the added ingredients, and stir at a high speed Uniform, forming a semi-dry powder;

[0059] (3) passing the semi-dry powder obtained in step (2) through a 40-mesh sieve to obtain semi-dry powder particles;

[0060] (4) Fill the semi-dry powder granules obtained in step (3) into the mold and obtain the filter element green body after semi-dry pressing molding, place the filter element green body in a box filled with powdered activated carbon, and seal the box with a lid, between the lid and the box Seal it with c...

Embodiment 3

[0064] (1) Add 85 parts of diatomite, 10 parts of activated carbon, 2 parts of calcite, 2 parts of clay powder, 2 parts of dolomite, 3 parts of swollen starch, and 0.6 part of chromium trioxide into a high-speed mixer for high-speed mixing of dry powder;

[0065] (2) Weigh 4 parts of polyvinyl alcohol, mix the alcohol and polyvinyl alcohol evenly according to the mass ratio of 1:1, add the high mixer to stir, then add water accounting for 0.4 of the total weight of the total added ingredients, and stir at a high speed Uniform, forming a semi-dry powder;

[0066] (3) passing the semi-dry powder obtained in step (2) through a 40-mesh sieve to obtain semi-dry powder particles;

[0067] (4) Fill the semi-dry powder granules obtained in step (3) into the mold and obtain the filter element green body after semi-dry pressing molding, place the filter element green body in a box filled with powdered activated carbon, and seal the box with a lid, between the lid and the box Seal it wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com