Pre-hydrated mineral powder nanocrystalline nucleus early strengthening agent for steam-curing concrete and preparation method thereof

A prehydration and nanocrystalline technology, applied in the field of concrete admixtures, can solve problems such as failure to meet early strength requirements, slow cement hydration speed, and low activity, so as to improve production efficiency, early strength, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with examples.

[0016] Example 1-5

[0017] Prepare the prehydrated mineral powder nano crystal nucleus early strength agent for steam-cured concrete, the specific steps are as follows:

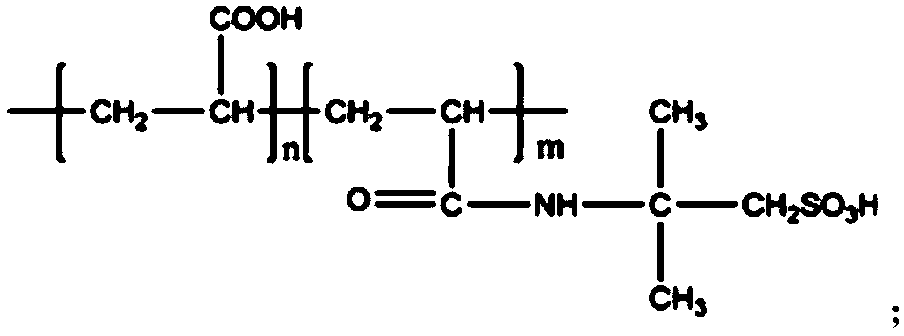

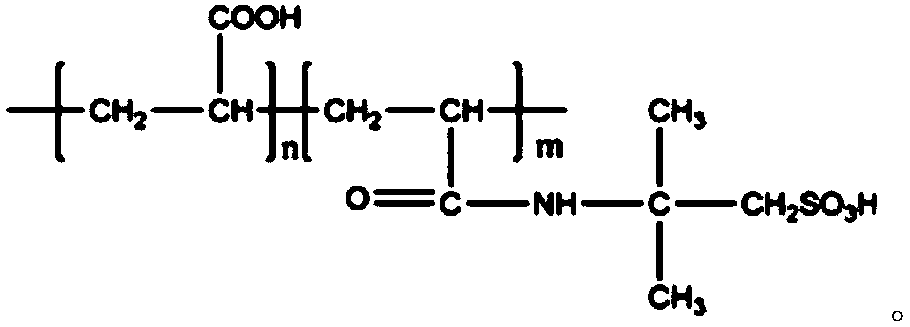

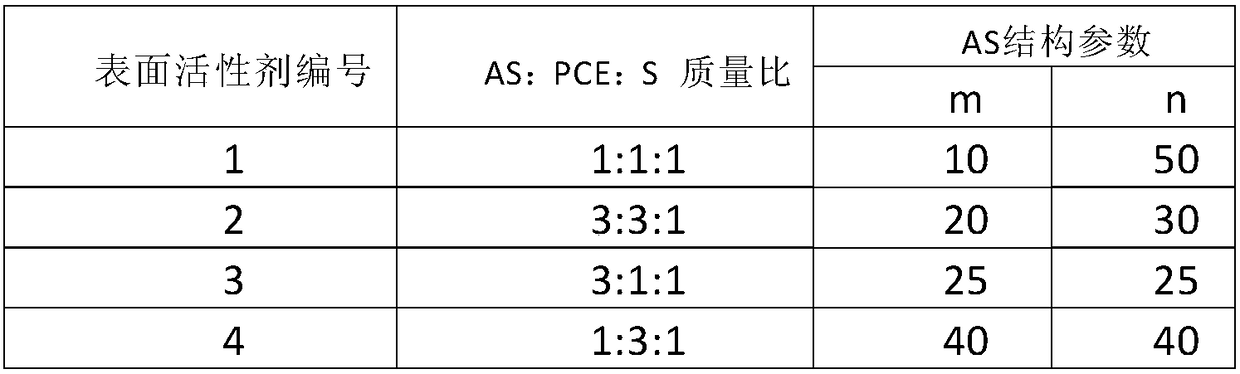

[0018] Mineral powder (particle size ≤ 20μm, mainly containing CaO, SiO 2 、Al 2 o 3 , MgO, Fe 2 o 3 ), the surface modifier and water are put into the ball mill tank in proportion, and the zirconia grinding body is added. Ball milling for 30 minutes, stop for 10 minutes, recorded as one cycle, use laser particle size analyzer to test particle size distribution, repeat ball milling for 3-5 cycles, until the median particle size of the ball milled powder is 200-400nm, obtained for steam curing Prehydrated mineral powder nano crystal nucleus early strength agent for concrete.

[0019] The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com