a sound-absorbing felt

A sound-absorbing and sound-absorbing layer technology, which is applied in the field of sound-absorbing materials, can solve the problems of low-frequency sound-absorbing effect, etc., and achieve good sound-absorbing effect, avoid damp subsidence, and fiber flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

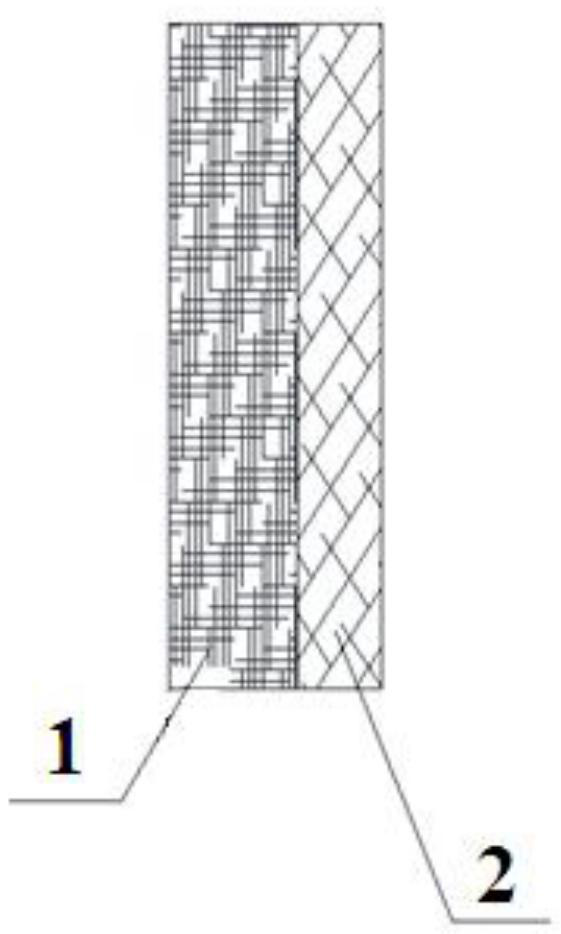

Image

Examples

Embodiment 1

[0031] This embodiment provides a sound-absorbing felt, which is composed of a first sound-absorbing layer and a second sound-absorbing layer that are stacked. The first sound-absorbing layer is obtained by acupuncture with polyacrylonitrile pre-oxidized fibers, and the surface density is 5kg / m 2 , thickness 1cm; the second sound-absorbing layer is also made of polyacrylonitrile pre-oxidized fiber through acupuncture process, with a surface density of 1.5kg / m 2 , thickness 4cm.

[0032] When acupuncture is performed, the barbed hook on the needle drives the fibers on the surface and subsurface of the main layer of the polyacrylonitrile preoxygenated fiber to move from the plane direction of the main layer to the vertical direction, causing the fibers to shift up and down and change the extension direction. , forming polyacrylonitrile pre-oxidized fiber clusters whose extension direction is 85-95° to the main body layer.

[0033] The polyacrylonitrile preoxygenated fibers used...

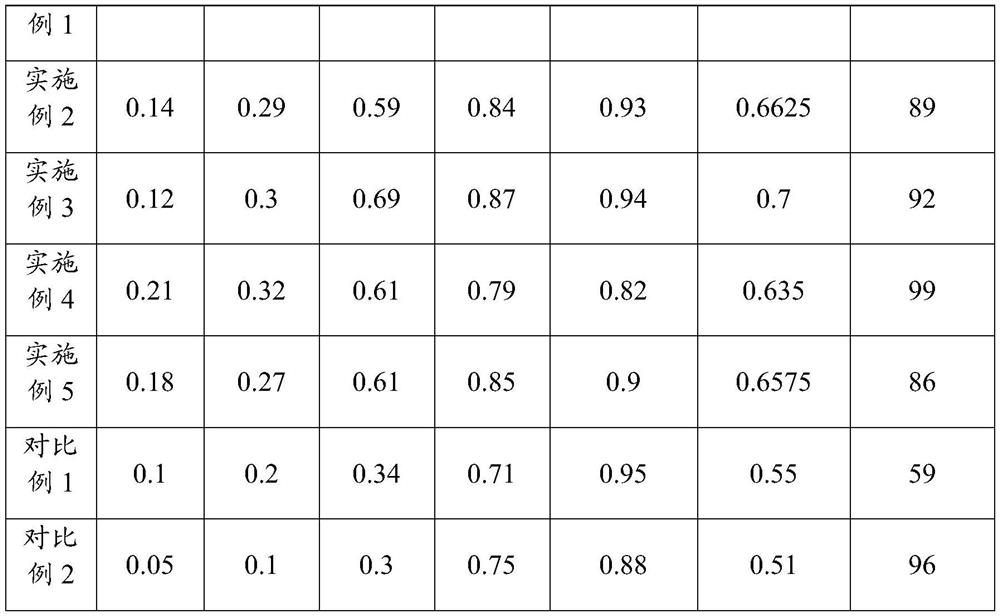

Embodiment 2

[0036] This embodiment provides a sound-absorbing felt, which is composed of a first sound-absorbing layer and a second sound-absorbing layer that are stacked. The first sound-absorbing layer is obtained by acupuncture with polyacrylonitrile pre-oxidized fibers, and the surface density is 2kg / m 2 , with a thickness of 2cm; the second sound-absorbing layer is also made of polyacrylonitrile pre-oxidized fiber for acupuncture, with an area density of 3kg / m 2 , thickness 3cm.

[0037] The polyacrylonitrile preoxygenated fibers used in this embodiment have a length ranging from 6 to 12 cm and a diameter of 11 to 20 μm.

[0038] When in use, the first sound-absorbing layer faces the sound source as the side close to the sound source, and the second sound-absorbing layer as the side away from the sound source.

Embodiment 3

[0040] This embodiment provides a sound-absorbing felt, which is composed of a first sound-absorbing layer and a second sound-absorbing layer that are stacked. The first sound-absorbing layer is obtained by acupuncture with polyacrylonitrile pre-oxidized fibers, and the surface density is 1.5kg / m 2 , with a thickness of 3cm; the second sound-absorbing layer is also made of polyacrylonitrile pre-oxidized fiber for acupuncture, with a surface density of 4kg / m 2 , thickness 2cm.

[0041] When acupuncture is performed, the barbed hook on the needle drives the fibers on the surface and subsurface of the main layer of the polyacrylonitrile preoxygenated fiber to move from the plane direction of the main layer to the vertical direction, causing the fibers to shift up and down and change the extension direction. , forming polyacrylonitrile pre-oxidized fiber clusters whose extension direction is 85-95° to the main body layer.

[0042] The polyacrylonitrile preoxygenated fibers used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com