A kind of manufacturing method of perforated needle compound surfacing welding

A manufacturing method and perforating needle technology, which can be used in manufacturing tools, welding equipment, arc welding equipment, etc., can solve problems such as large problems in service life, and achieve the effect of improving service life, strong impact resistance and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

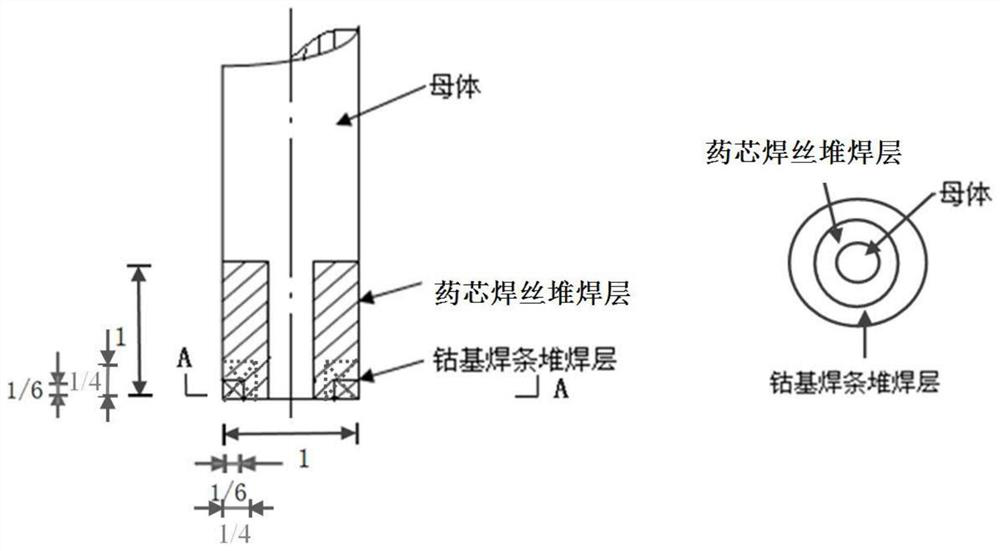

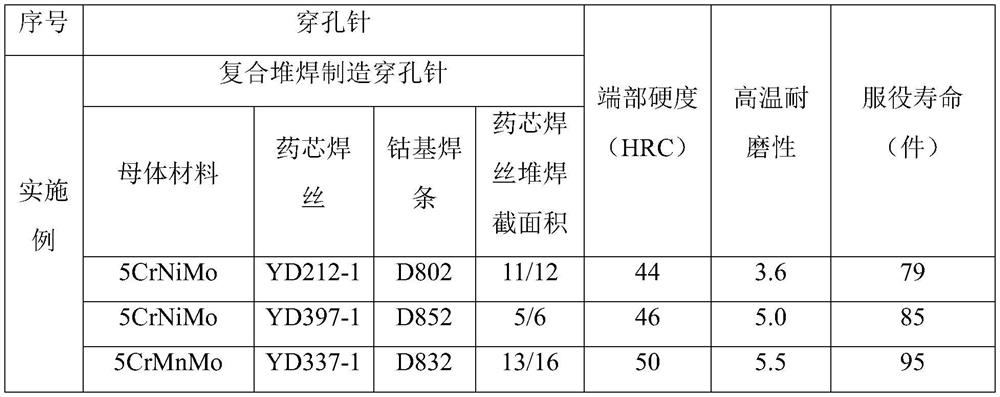

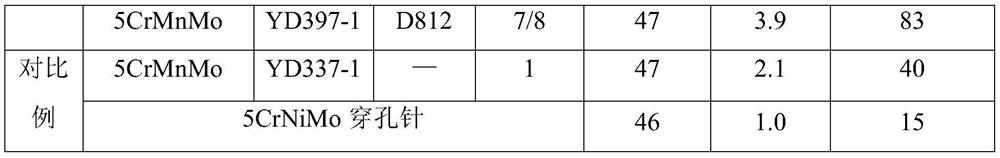

[0025] This embodiment proposes a combination of two materials, YD212-1 flux core and cobalt-based electrode D802, for surfacing welding to manufacture the perforating needle head to manufacture a composite perforating needle. Such as figure 1 As shown, the specific method is as follows:

[0026] Welding method: using CO 2 Gas shielded welding + manual arc welding.

[0027] Welding sequence: first use CO at the needle head part of the punching needle parent body 2 Gas-shielded welding ring-shaped surfacing welding needle head, the welding wire used is YD212-1 flux-cored welding wire, and then cobalt-based electrode D802 is surfacing on the outermost side of the needle head, and the total cross-sectional area of flux-cored welding wire and cobalt-based electrode surfacing is 1 , The cross-sectional area of flux-cored wire annular surfacing is 11 / 12.

[0028] Welding material: CO 2 YD212-1 flux-cored wire for gas shielded welding, cobalt-based electrode D802 for manual ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com