Metal hydride reactor gradiently filled with expanded graphite

A technology of expanded graphite and gradient filling, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of decreased hydrogen storage density and volumetric heat storage density, and achieve increased heat storage efficiency and hydrogen absorption reaction rate , is conducive to the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

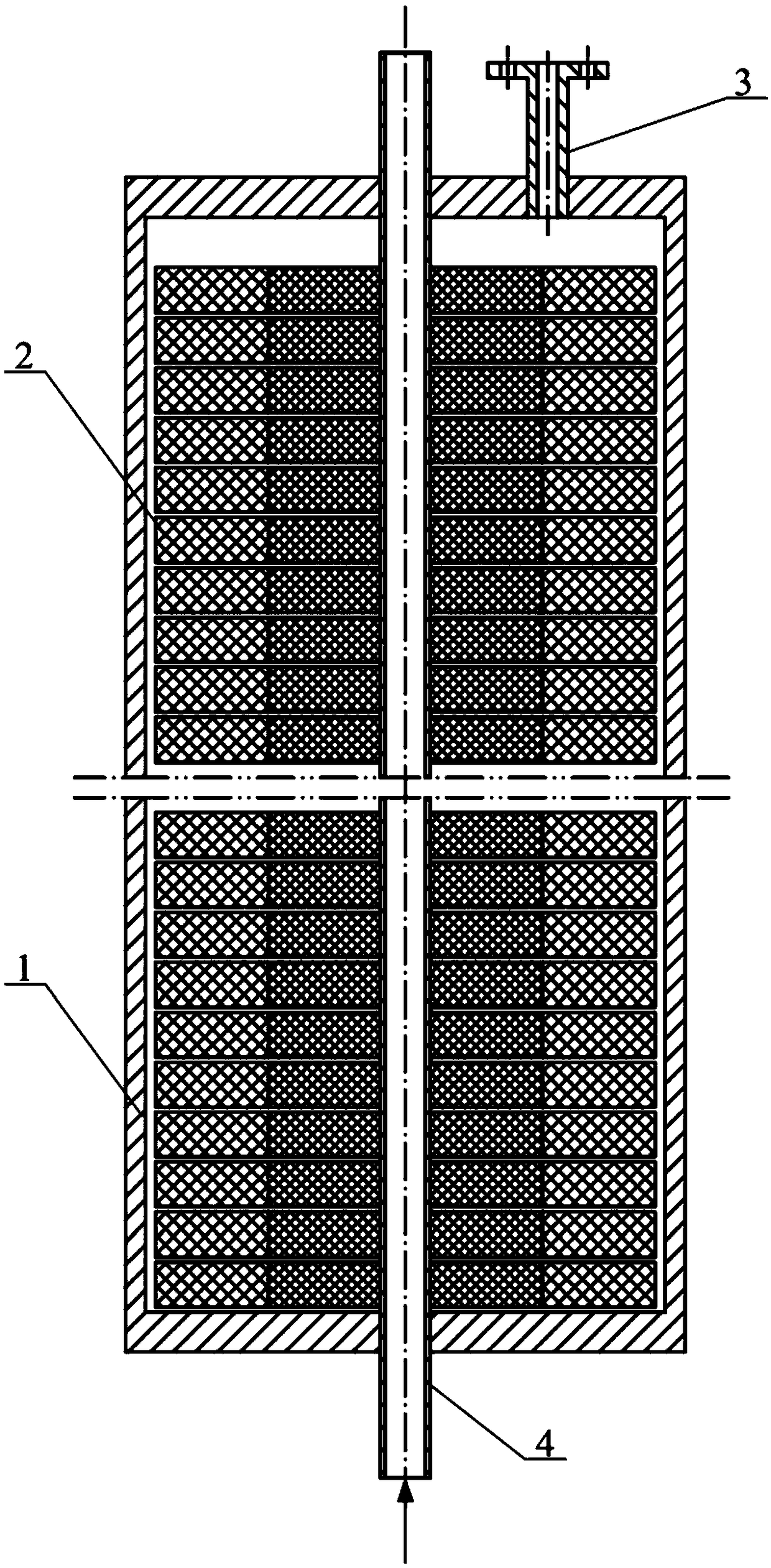

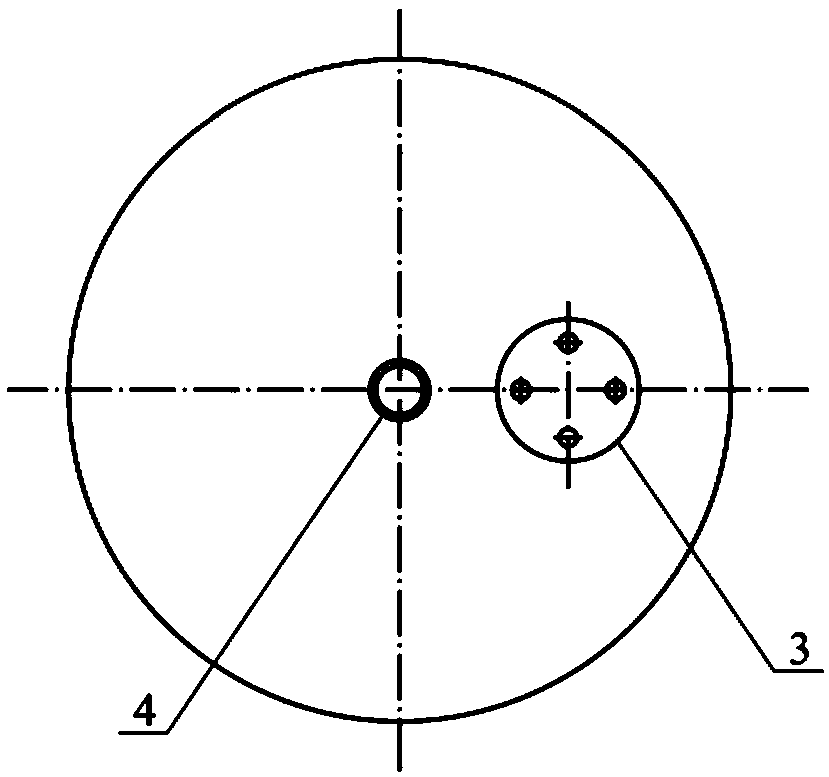

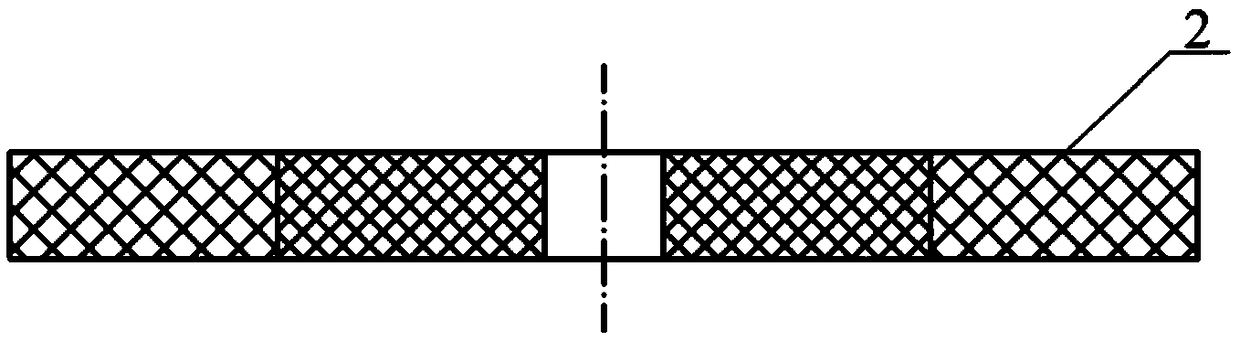

[0029] Such as figure 1 , figure 2 with Figure 7 As shown, a metal hydride reactor filled with expanded graphite gradiently includes a shell, a reaction bed, a hydrogen gas inlet and outlet pipe, and a heat exchange tube. The reaction bed is arranged inside the shell to form a reaction chamber, and the hydrogen gas enters The outlet pipe is arranged on the outer surface of the shell, and the heat exchange tube passes through the center of the reaction bed, which is made of composite materials mixed and pressed by multi-layer metal hydride and expanded graphite. The mass content of each layer of expanded graphite gradually decreases from the inside to the outside. The shell 1 is a cylindrical shell with an inner diameter of 104 mm and an inner volume of 4.25 L. The inner diameter of the heat exchange tube 4 is 8 mm. The material of the shell 1 and the heat exchange tube 4 is For 316L stainless steel, the mass content of expanded graphite varies according to the direction gr...

Embodiment 2

[0032] Such as Figure 1 to Figure 4 , Figure 7 As shown, a metal hydride reactor filled with expanded graphite gradiently includes a shell, a reaction bed, a hydrogen gas inlet and outlet pipe, and a heat exchange tube. The reaction bed is arranged inside the shell to form a reaction chamber, and the hydrogen gas enters The outlet pipe is arranged on the outer surface of the shell, and the heat exchange tube passes through the center of the reaction bed, which is made of composite materials mixed and pressed by multi-layer metal hydride and expanded graphite. The mass content of expanded graphite in each layer decreases gradually from the inside to the outside. Shell 1 is a cylindrical shell with an inner diameter of 104mm and an inner volume of 4.25L. The inner diameter of heat exchange tube 4 is 8mm. The material of shell 1 and heat exchange tube 4 is 316L stainless steel. The heat exchange fluid in heat exchange tube 3 is heat transfer oil. Dowtherrm A, the inlet veloci...

Embodiment 3

[0036] Such as figure 1 , figure 2 , Figure 5 to Figure 7As shown, a metal hydride reactor filled with expanded graphite gradiently includes a shell, a reaction bed, a hydrogen gas inlet and outlet pipe, and a heat exchange tube. The reaction bed is arranged inside the shell to form a reaction chamber, and the hydrogen gas enters The outlet pipe is arranged on the outer surface of the shell, and the heat exchange tube passes through the center of the reaction bed, which is made of composite materials mixed and pressed by multi-layer metal hydride and expanded graphite. The mass content of expanded graphite in each layer decreases gradually from the inside to the outside. Shell 1 is a cylindrical shell with an inner diameter of 104mm and an inner volume of 4.25L. The inner diameter of heat exchange tube 4 is 8mm. The material of shell 1 and heat exchange tube 4 is 316L stainless steel. The heat exchange fluid in heat exchange tube 3 is heat transfer oil. Dowtherrm A, the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com