Multi-phase-change material sub-cavity casing pipe type phase change heat accumulator

A phase-change heat storage and sleeve-type technology, which is applied in heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problems of low solar energy density, radiation intensity rarity, instability, etc., to achieve The effect of enhancing the heat exchange area, improving the overall heat storage performance, and increasing the melting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

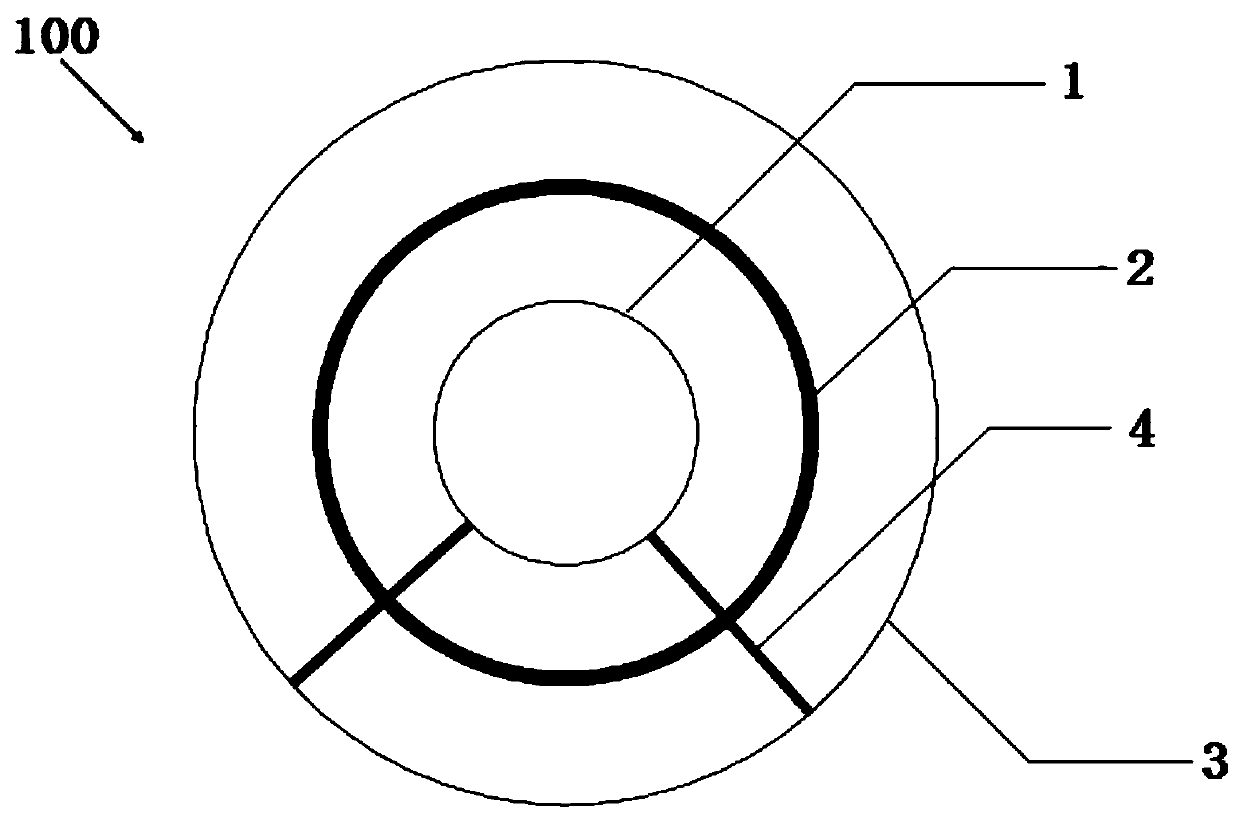

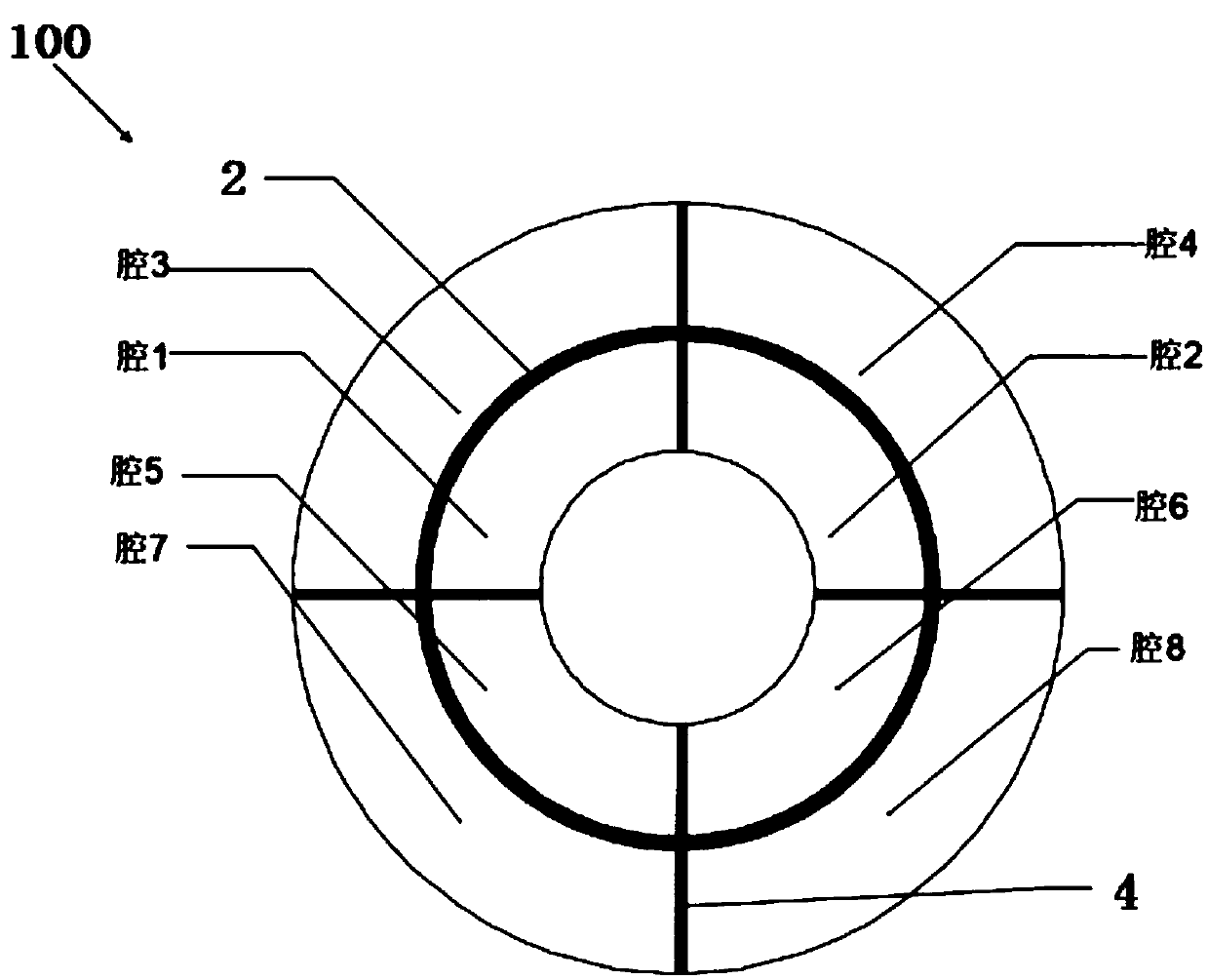

[0032] figure 2 Schematic diagram of the structure of an embodiment of the present invention.

[0033] Such as figure 2 As shown, the multi-phase change material split-cavity casing type phase-change heat accumulator 100 of this embodiment is a horizontal phase-change heat accumulator, which is a horizontally upper and lower chamber-type heat accumulator, including: middle round tubes 1, 1 A stainless steel sub-cavity wall 2, a heat exchange tube 3 and four stainless steel fins 4, the sub-cavity wall 2 and the ribs 4 can also adopt other metals with high thermal conductivity. The four fins 4 vertically pass through a sub-chamber wall 2 and the heat exchange tube 3 to form 8 sub-chambers, and the contact between the middle tube 1 and the fins 4 is welded and sealed, and the 8 sub-chambers are divided into A, B, Place different phase change materials in the four areas C and D, such as: paraffin, fatty acid or other phase change materials. Since the melting speed and trend of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com