Anti-adhesive material stirring device for novel material production

A technology of stirring device and anti-sticking wall, which is applied to mixers with rotary stirring devices, accessories of mixers, transportation and packaging, etc. problem, to achieve the effect of reducing the steps of sorting and searching, excellent anti-stick wall effect, and remarkable stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

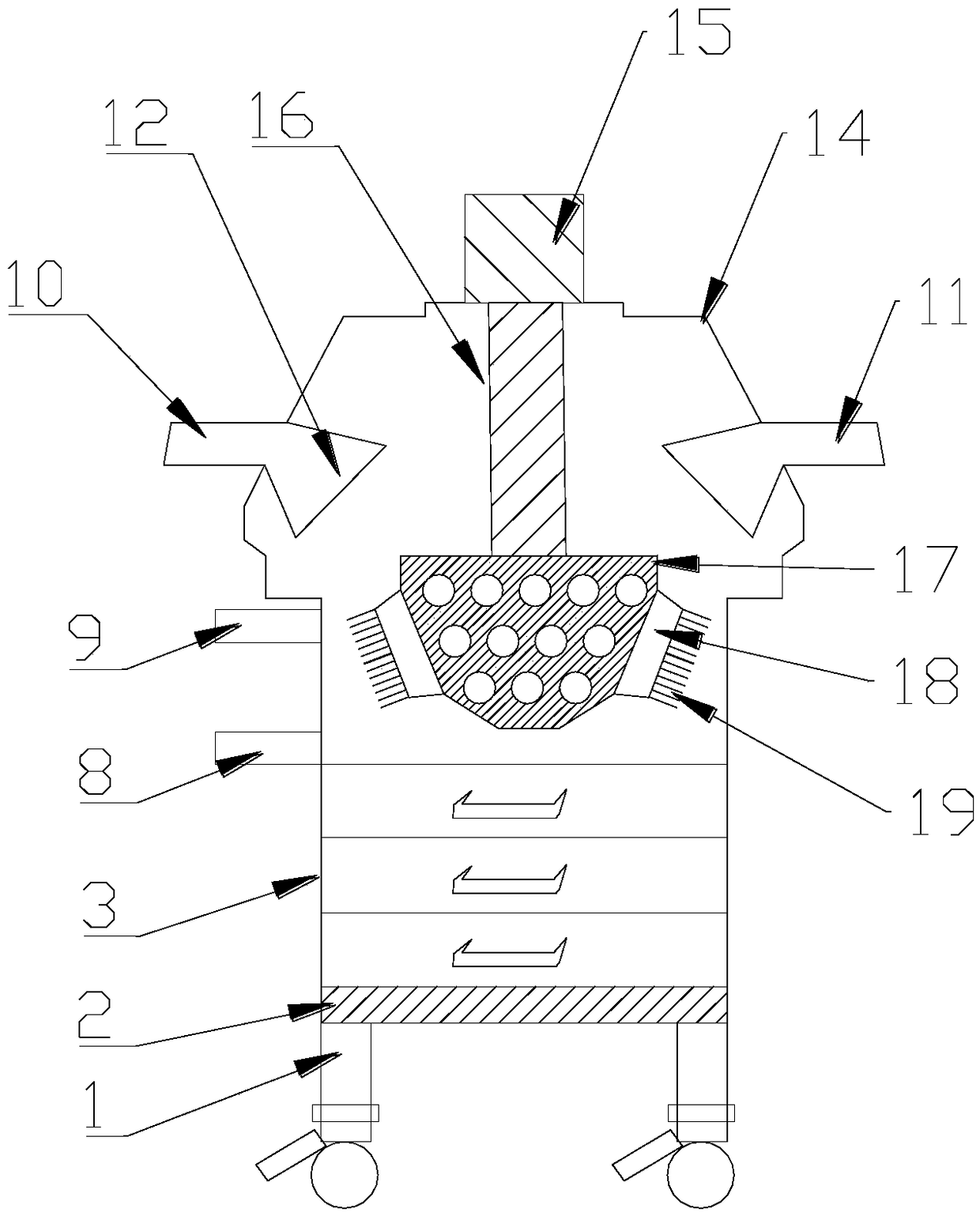

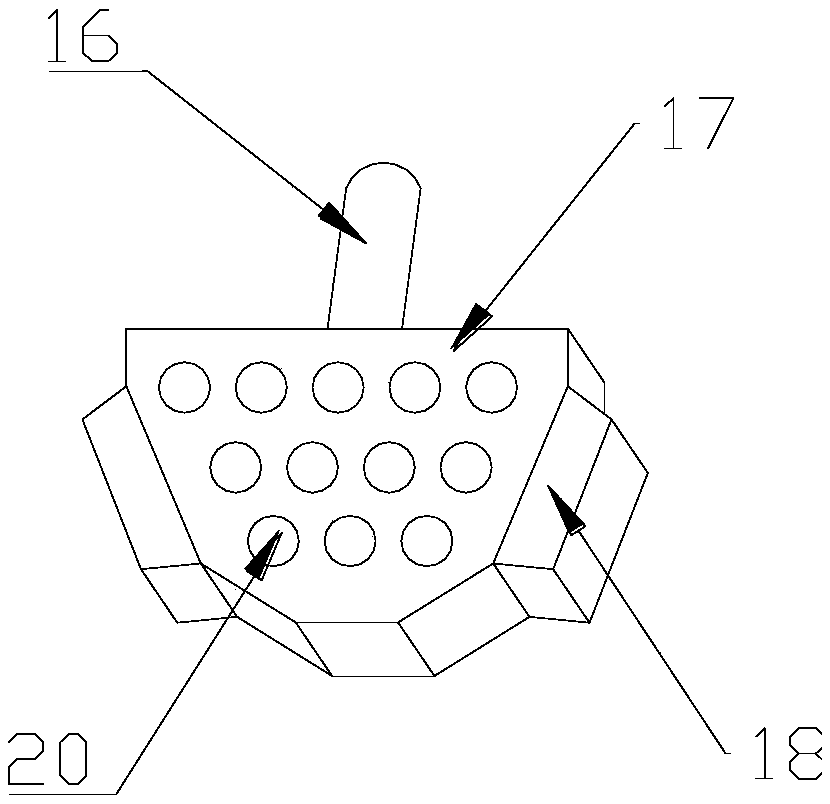

[0026] see Figure 1-5 , a new material production anti-adhesive wall material stirring device, including a storage box 3, a stirring box 14, a stirring paddle 17, a cleaning brush 19 and a nozzle 12;

[0027] The stirring box 14 is arranged on the upper end of the storage box 3, and the storage box 3 is arranged on the base plate 2, and the lower end of the base plate 2 is evenly provided with several universal wheels 1, and the universal wheels 1 are provided with The moving rod, through the universal wheel 1, can realize the movement and braking of the bottom plate 2 and the storage box 3 and the mixing box 14 on it, which is convenient to move and improves flexibility;

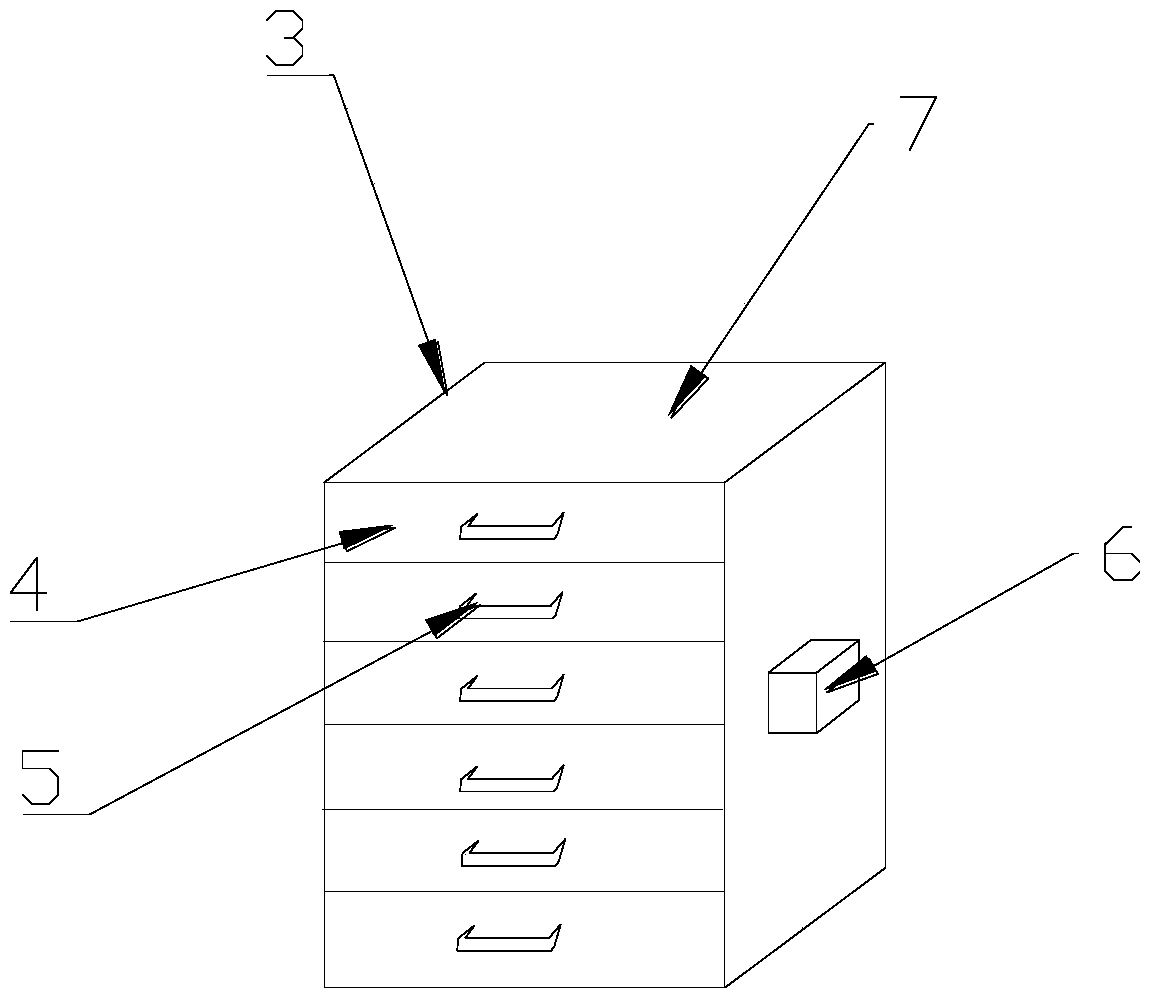

[0028] The storage box 3 includes a box body 7, the front of the box body 7 is provided with a plurality of drawers 4, and the outer front of the drawer 4 is provided with a pull ring 5. In this embodiment, preferably, the pull ring 5 The material is engineering plastics, and a variety of production mater...

Embodiment 2

[0033] see Figure 1-5 , a new material production anti-sticking wall material stirring device, including a storage box 3, a stirring box 14, a stirring paddle 17, a cleaning brush 19 and a nozzle 12; the mixing box 14 is arranged on the upper end of the storage box 3, and the Storage box 3 is arranged on the base plate 2, and described base plate 2 lower end is evenly provided with several universal wheels 1, can realize the movement of base plate 2 and storage box 3 and stirring box 14 on it by universal wheels 1, improves flexibility;

[0034] The storage box 3 includes a box body 7, the front of the box body 7 is provided with a plurality of drawers 4, and the outer front of the drawer 4 is provided with a pull ring 5. In this embodiment, preferably, the pull ring 5 The material is engineering plastics, and a variety of production materials or production tools can be classified and stored through a plurality of drawers 4, which is convenient and quick to use, reduces the ...

Embodiment 3

[0039] see Figure 1-5 , a new material production anti-sticking wall material stirring device, including a storage box 3, a stirring box 14, a stirring paddle 17, a cleaning brush 19 and a nozzle 12; the mixing box 14 is arranged on the upper end of the storage box 3, and the The storage box 3 is arranged on the base plate 2, and the lower end of the base plate 2 is evenly provided with several universal wheels 1, and the universal wheels 1 are provided with a brake lever, and the base plate 2 and the upper end of the base plate 2 can be realized through the universal wheels 1. The movement and braking of the storage box 3 and the mixing box 14 are easy to move and improve flexibility;

[0040] The storage box 3 includes a box body 7, the front of the box body 7 is provided with a plurality of drawers 4, and the outer front of the drawer 4 is provided with a pull ring 5. In this embodiment, preferably, the pull ring 5 The material is engineering plastics, and a variety of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com