High-fiber high-protein highland barley and production method thereof

A production method and high-protein technology, applied in food shaping, food science, application, etc., can solve the problems of reducing the effect, increasing blood sugar content, etc., and achieve easy brewing and aging, moist taste, protein content, high efficiency and low consumption rehydration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

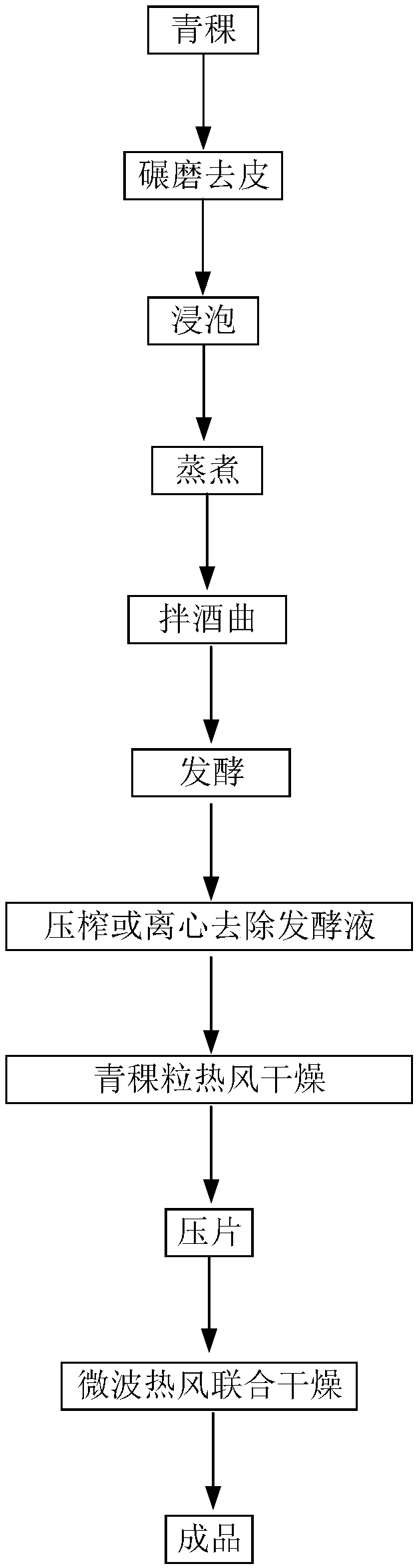

Method used

Image

Examples

Embodiment 1

[0054] 1) Cleaning and peeling of highland barley: the raw material of highland barley uses grain cleaning equipment to remove impurities in the highland barley, and then grinds and removes 20% of the highland barley cortex with a rice milling and peeling machine.

[0055] 2) Fermentation to remove sugar: take peeled highland barley grains, add twice as much water and soak for 12 hours at room temperature. Soak the highland barley that absorbs enough water, wash it, filter out the open water, put it in a cooking pot and cook it under normal pressure for 1.5 hours, and the water absorption rate is 150-155%; spread it to cool to 30°C, add distiller’s yeast with 0.4% weight of the highland barley before cooking, and pack Put it into a fermenter, cover and seal it, and ferment at 30°C for 70h. After the fermentation is complete, add 2 times the weight of the fermented highland barley and soak in clean water for 6 hours, filter to remove the liquid (the filtrate can be used as high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com