An electrically conductive composite material and a preparation method thereof

A technology of conductive composite materials and conductive substrates, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., and can solve the problems of low conductivity or insulative substrates that are difficult to disperse evenly, and the conductivity of conductive composite materials is uneven.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

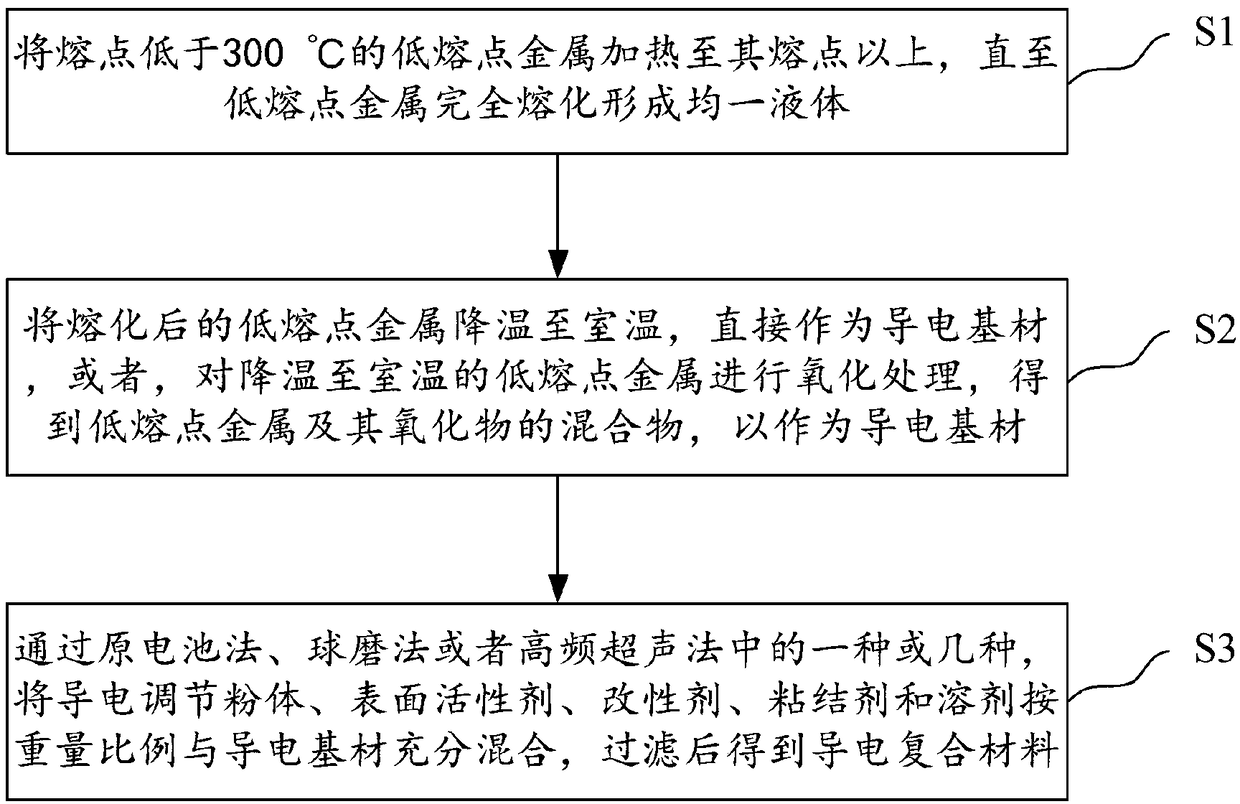

[0046] In addition, an embodiment of the present invention provides a method for preparing a conductive composite material, which is used to prepare the conductive composite material described in any one of the above, specifically, as figure 1 as shown, figure 1 The flow chart of the preparation method of the conductive composite material provided by the embodiment of the present invention, the preparation method of the conductive composite material includes:

[0047] Step S1, heating the low-melting-point metal whose melting point is lower than 300°C to above its melting point, until the low-melting-point metal is completely melted to form a uniform liquid;

[0048] Step S2, cooling the melted low-melting-point metal to room temperature and directly using it as a conductive substrate, or performing oxidation treatment on the low-melting-point metal cooled to room temperature to obtain a mixture of low-melting-point metal and its oxide as a conductive substrate ;

[0049] Op...

Embodiment 1

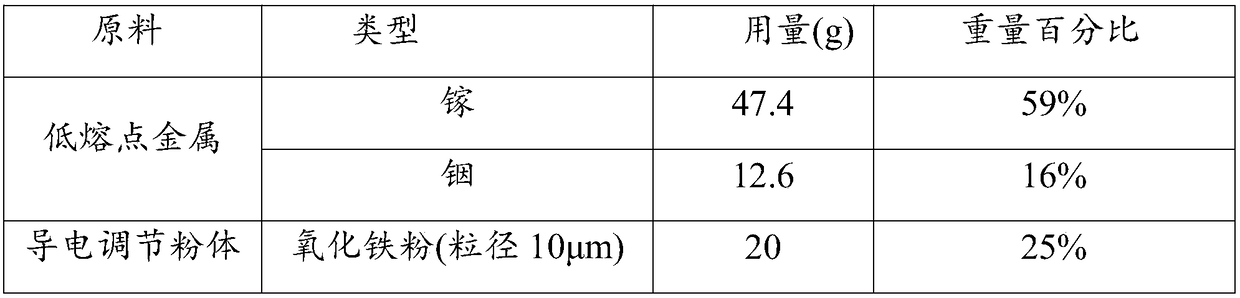

[0059] The raw materials for the preparation of the conductive composite material are shown in the following table. The ball milling method is adopted in the step S3 of the preparation method, specifically, a planetary ball mill is used:

[0060]

[0061] Conductivity of conductive composite material: 4800S / m

Embodiment 2

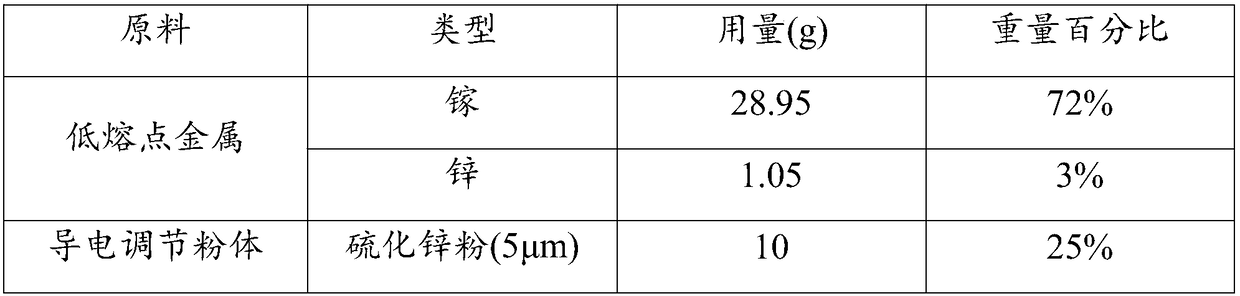

[0063] The raw materials for the preparation of the conductive composite material are shown in the following table. The ball milling method is adopted in the step S4 of the preparation method, specifically, a planetary ball mill is used:

[0064]

[0065] Conductivity of conductive composite material: 4400S / m

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com