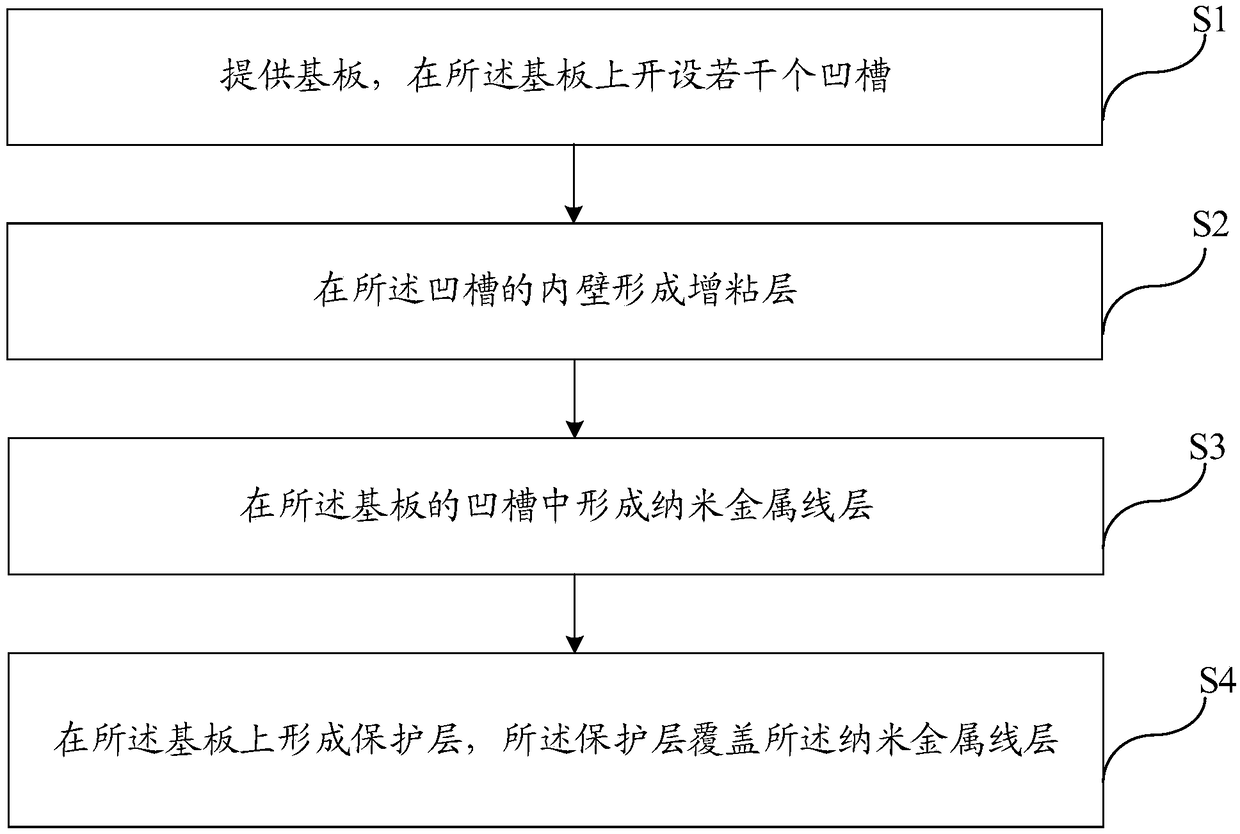

A thin film laminated structure and a manufacturing method thereof

A technology of a laminated structure and manufacturing method, applied in the field of touch screens, can solve problems such as high cost, poor anti-damage performance, and large resistance, and achieve the goals of reducing the possibility of movement, increasing the contact area, and enhancing adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

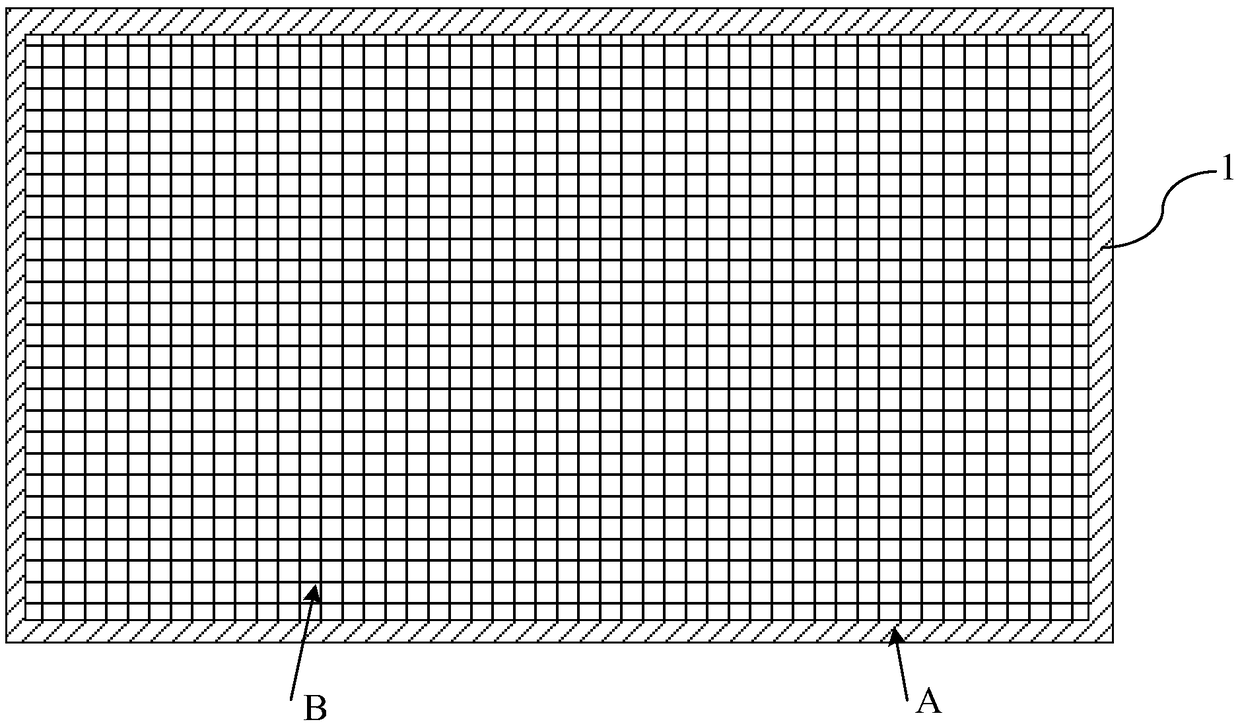

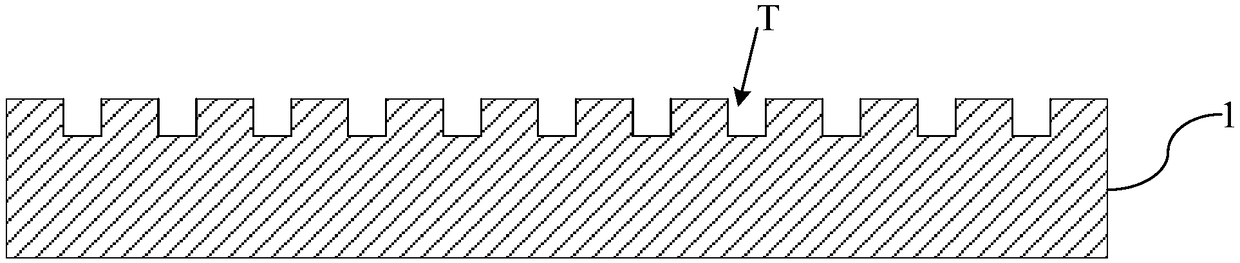

[0031] As mentioned in the background art, although metal oxides such as ITO have excellent light transmittance and electrical conductivity, they are not suitable for the preparation of flexible devices due to the problems of high resistance, high cost, and poor damage resistance. Therefore, the industry is trying to develop materials that can replace ITO, such as conductive polymers, carbon nanotubes, graphene, and silver nanowires. Among them, silver nanowires (SilverNano Wires, SNW) have a transparent conductive film surface due to the nanoscale size effect. It is flat, resistant to bending, and has good electrical conductivity. It is considered to be the preferred alternative material for metal oxides.

[0032] However, the adhesion of traditional silver nanowires is poor. In order to solve the problem of adhesion between silver nanowires and substrates, the inventors once tried to add OC (over coater) glue after coating silver nanowires; however, although this technology ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com