Phase interface measurement device and method for melting/solidification process of composite phase change material based on thermochromic liquid crystal

A composite phase change material and thermochromic liquid crystal technology, applied in the investigation stage/state change, etc., can solve the problem that the solid-liquid two-phase interface of the composite phase change material is invisible, interferes with the melting/solidification process of the composite phase change material, and cannot be adopted Heat storage cavity and other problems, to achieve the effects of eliminating influence, high temperature resolution, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the following will further describe the embodiments of the present invention in detail in conjunction with the accompanying drawings.

[0028] Such as figure 1 As shown, the phase interface measurement device for the melting / solidification process of composite phase change materials based on thermochromic liquid crystals includes a hot end, a cold end, a test body and a data acquisition system;

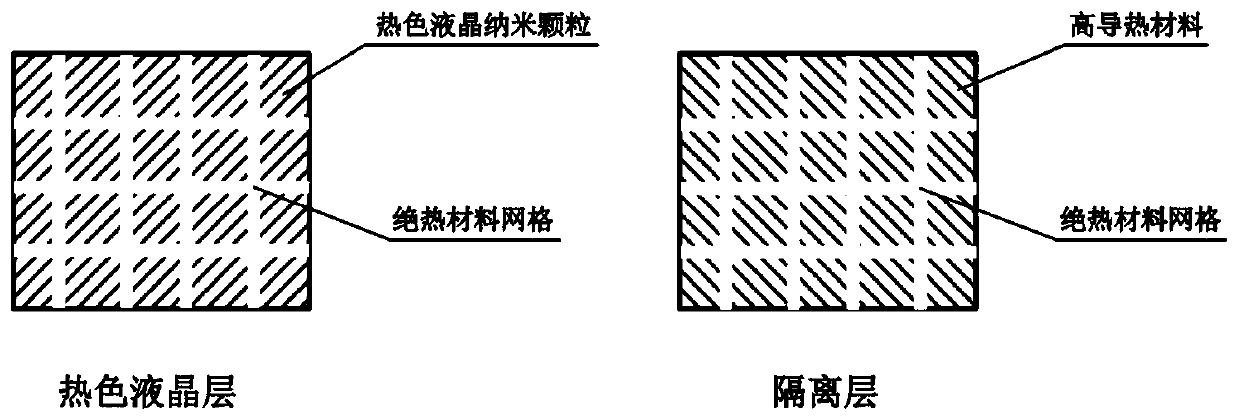

[0029] The hot end includes a heat generating element 1 and a hot end heat conduction element 2 connected to the heat generating element 1; the cold end includes a refrigeration element 4 and a cold end heat conduction element 3 connected to the refrigeration element 4; The test body includes a thermal storage chamber 5, a thermochromic liquid crystal layer 7, an isolation layer 8 and a vacuum glass layer 9; the data acquisition system includes an acquisition instrument for detectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com