Method for analyzing elemental copper in organosilicone slag slurry

An organosilicon slag and element technology, applied in thermal excitation analysis, material excitation analysis, etc., can solve the problems of forming acid mist and gelatinous substances, complex composition of organosilicon slag, and irritating odor, etc. Simple instrument operation, fast and efficient analytical methods, and simple sample processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

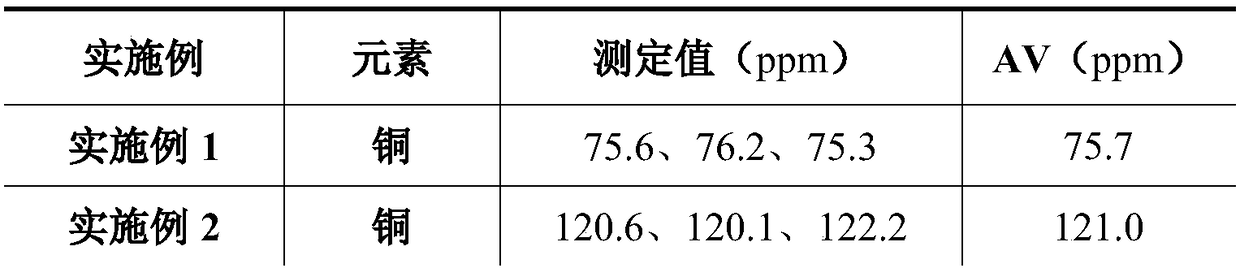

Embodiment 1

[0022] Weigh 20g of the slurry from the washing tower reboiler or the slurry distillation device of the organosilicon monomer synthesis device and place it in a 200ml beaker, add 100ml of ethanol to completely soak the slurry, stir and let it stand for 2 hours before removing the slurry The solution was filtered with suction, and then the filter cake was dried in an oven at 60°C for 2 hours.

[0023] After cooling, weigh 0.25g into the crucible, add 10ml of hydrofluoric acid, and after the violent reaction stops, add nitric acid dropwise until the sample is completely dissolved, then add 1ml of perchloric acid, continue heating to dissolve the sample completely, until no more sparks Take off the white smoke of perchloric acid, take it out and cool it, add 5ml of hydrochloric acid, wash the wall of the dish with a little water, heat until the residue is completely dissolved, cool to room temperature, transfer it into a 100ml volumetric flask, dilute with water to the mark and sh...

Embodiment 2

[0028] Weigh 40g of the slurry from the washing tower reboiler or the slurry distillation device of the organosilicon monomer synthesis unit and place it in a 500ml beaker, add 200ml of ethanol to completely soak the slurry, stir and let it stand for 2 hours before the slurry The solution was filtered with suction, and then the filter cake was dried in an oven at 60°C for 2 hours.

[0029] After cooling, weigh 0.4g into the crucible, add 10ml of hydrofluoric acid, and after the violent reaction stops, add nitric acid dropwise until the sample is completely dissolved, then add 1ml of perchloric acid, continue heating to dissolve the sample completely, until no more sparks Take off the white smoke of perchloric acid, take it out and cool it, add 5ml of hydrochloric acid, wash the wall of the dish with a little water, heat until the residue is completely dissolved, cool to room temperature, transfer it into a 100ml volumetric flask, dilute with water to the mark and shake well, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com