Hydrocarbon generation and expulsion characterization and evaluation method of source rock pyrolysis/shale oil in-situ modification

An evaluation method and in-situ modification technology, applied in the preparation of test samples, material analysis using wave/particle radiation, and measurement devices, etc., can solve the problems of rock microstructure changes, product discharge process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

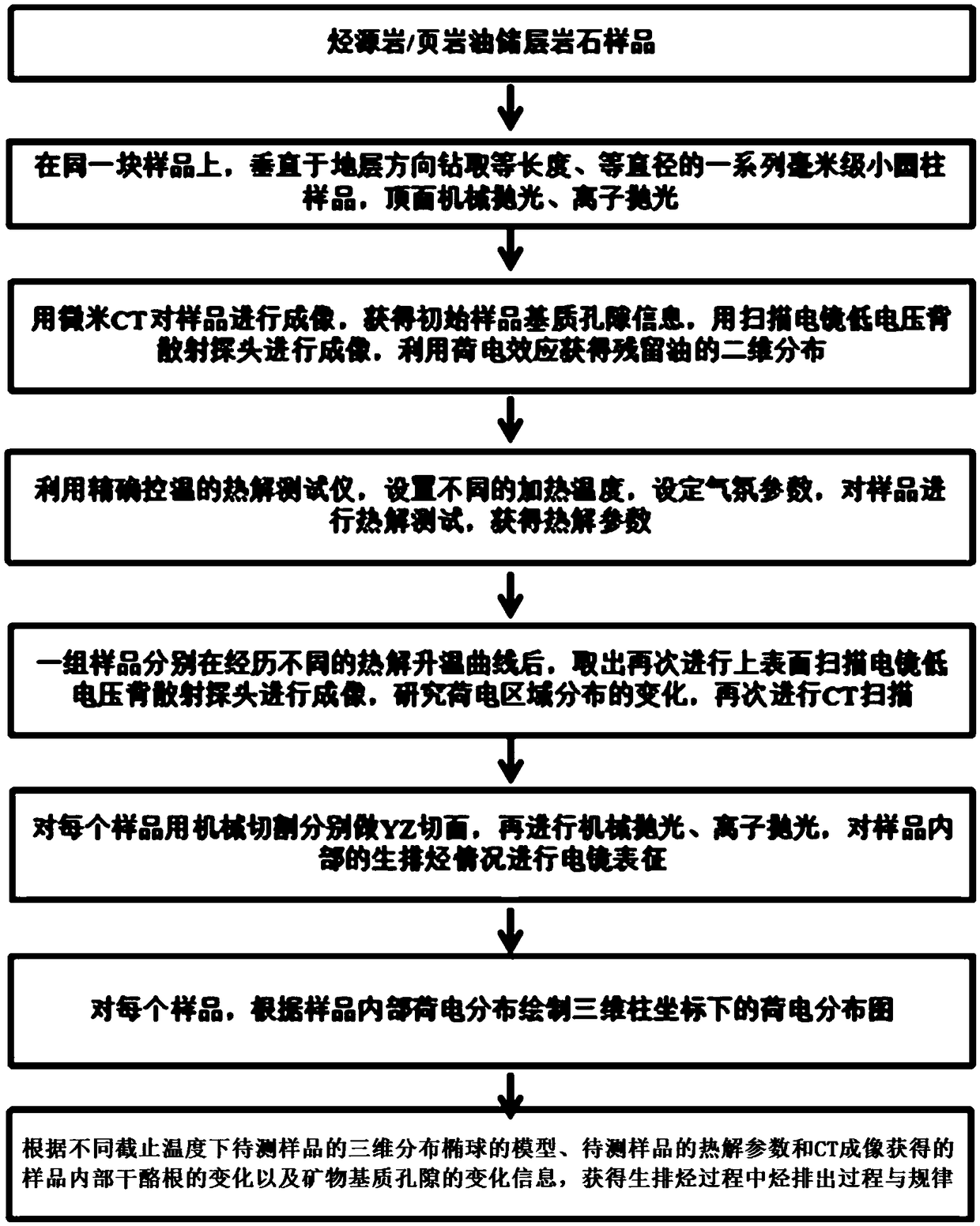

[0054] This example provides a hydrocarbon generation and expulsion characterization and evaluation method for source rock pyrolysis / shale oil in-situ upgrading, such as figure 1 shown, including the following steps:

[0055] Step 1. Collect the source rock rock samples of the Proterozoic Xiamaling Formation (which can be oil source rocks, gas source rocks, mudstone, mud shale, shale or shale oil reservoir rock samples); the TOC is 1%- 20%, kerogen maturity Ro is 0.1%-3.0%.

[0056] Step 2. Select the direction vertical to the formation, such as Figure 5 As shown, 5 pieces of cylindrical samples with a diameter of 5mm are drilled with a diamond drill, and the cylindrical samples are as follows figure 2 As shown, the samples are guaranteed to have the same upper surface, all cut according to the length of 5mm, the upper surface is polished (metallographic polishing method), and then argon ion polishing is performed to obtain a small cylindrical sample with a diameter of 5mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com