A monolithic abutment jointless bridge suitable for concrete rigid piles

A technology of integral abutments and seamless bridges, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of concrete cracking, large force at the connection between abutments and piles, poor deformation capacity, etc., to improve the deformation capacity. , The effect of stable deformation transfer and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings to help understand the application of the present invention, but the protection scope of the present invention is not limited to this specific example.

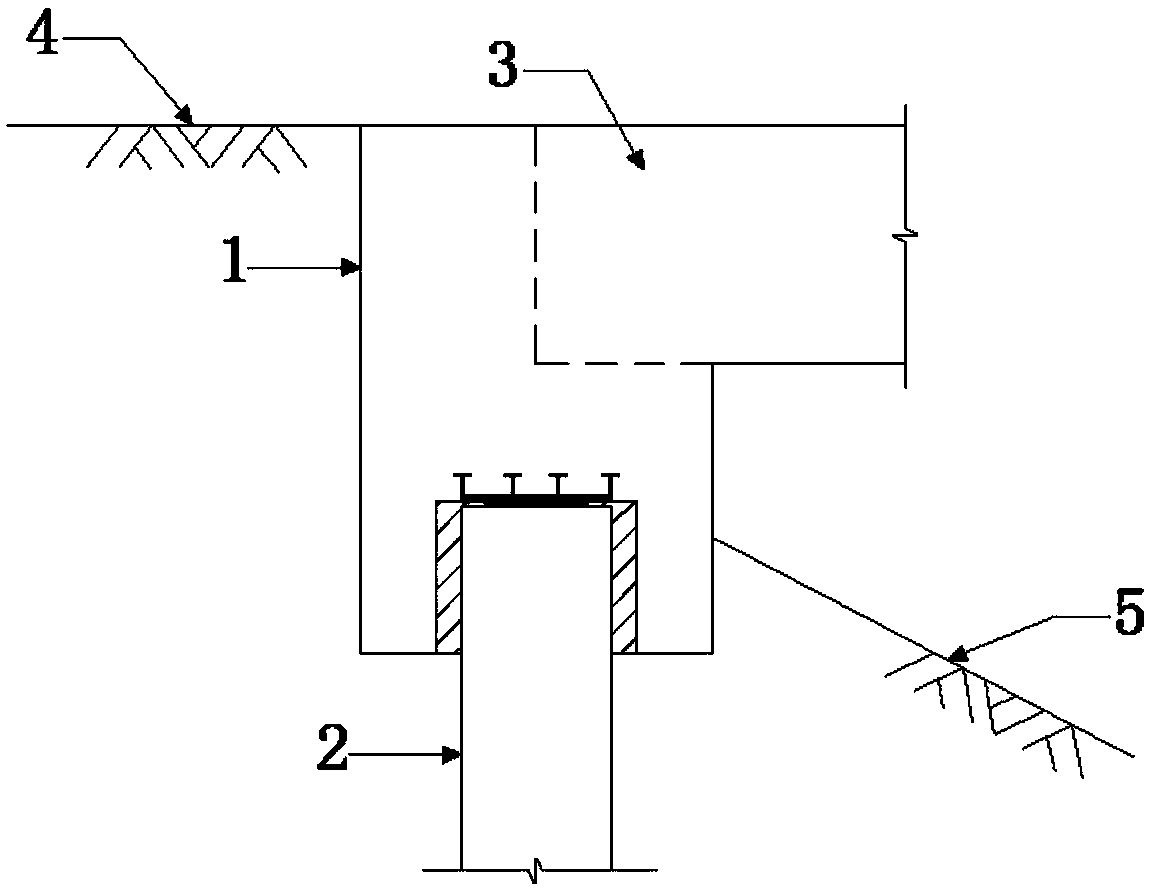

[0019] refer to Figure 1 ~ Figure 4 , an integral abutment seamless bridge suitable for concrete rigid piles, comprising a main girder 3, an abutment 1 and a pile foundation 3, a backfill subgrade 4 is arranged behind the abutment 1 and the main girder 3, and the pile The foundation 3 is embedded in the foundation 5, and the lower end of the abutment 1 and the upper end of the pile foundation 3 are slidably connected through a sliding connection structure;

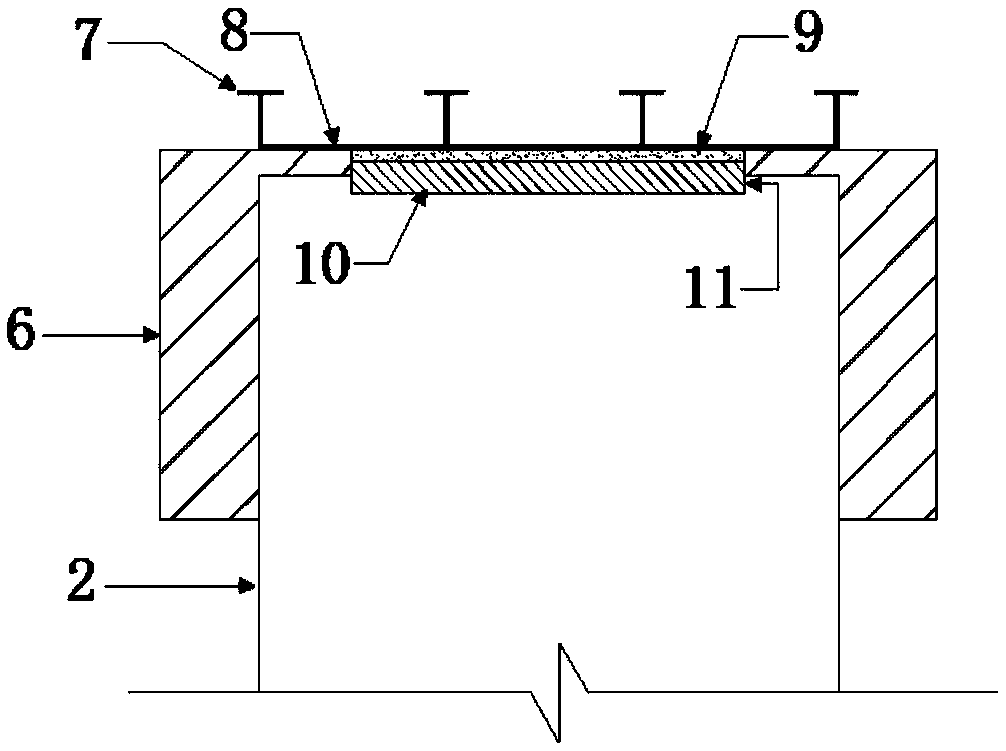

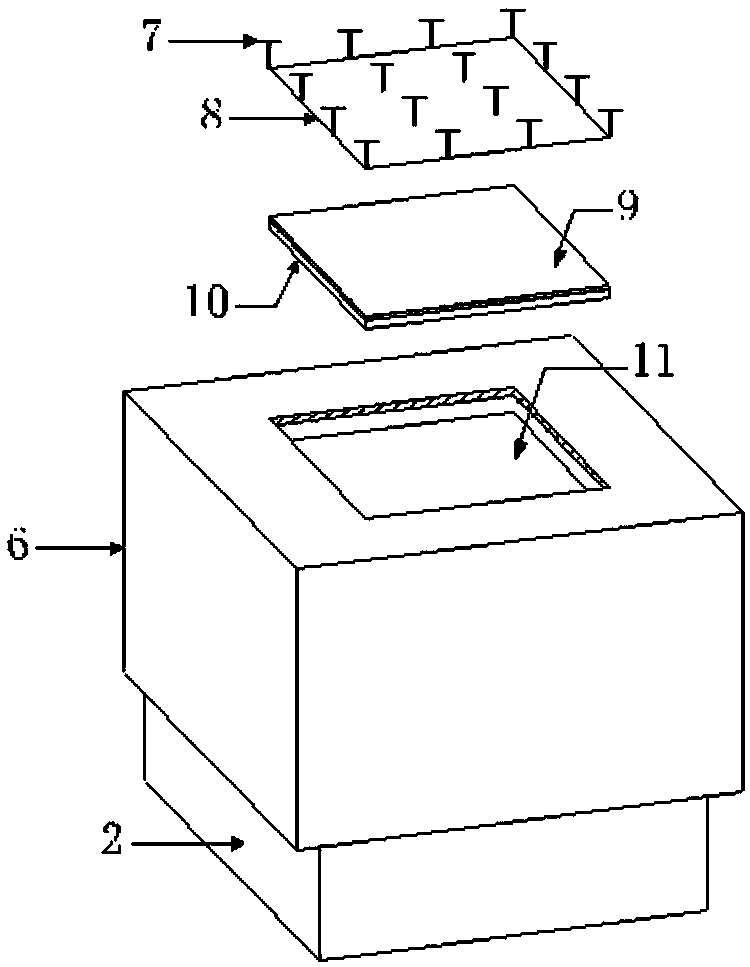

[0020] The sliding connection structure includes a compressible material 6, spacers 10, a sliding layer 9, thin steel plates 8 and pegs 7, and a layer of compressible material 6 is adhered on four sides of the top of the pile foundation 2, and the top of the pile fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com