Clothing care agent and preparation method thereof

A clothing care and softener technology, applied in the field of detergents, can solve the problems of high temperature resistance, poor water solubility, and structural damage, and achieve the effects of prolonging service life, inhibiting bacteria, and reducing irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

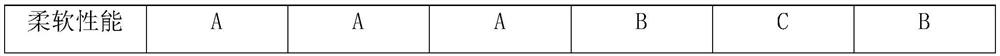

Examples

Embodiment 1

[0041] Embodiment 1: a kind of and nursing agent are prepared by the following method:

[0042] (1) Pre-mixing: Put 38.425kg deionized water, 3.5kg lauryl polyoxyethylene ether, and 3.5kg cocoyl glucoside into the batching kettle, heat it to 85°C at a heating rate of 6°C / min, and heat it at 450r Stirring 15min under the rotating speed of / min;

[0043] (2) Preparation: Add 5kg fatty acid polyoxyethylene ester, 2.5kg lauryl amidopropyl betaine, 2.5kg polyoxyethylene alkanolamide, 1kg cationic quaternary ammonium salt, 1kg water-based polyethylene wax emulsion to the premixed solution , 2kg chitosan, 1kg calendula extract, 1kg tannin, 0.15kg essence and 38.425kg deionized water, heated to 65°C at a heating rate of 3°C / min, and stirred for 70min at a speed of 350r / min, After cooling, the clothing care agent is obtained.

Embodiment 2

[0044] Embodiment 2: a kind of and nursing agent are prepared by following method:

[0045] (1) Pre-mixing: put 43kg deionized water, 2kg lauryl polyoxyethylene ether, and 2kg cocoyl glucoside into the batching kettle, heat it to 80°C at a heating rate of 5°C / min, and heat it at 400r / min Stir for 20 minutes at a rotating speed;

[0046] (2) Preparation: Add 3kg fatty acid polyoxyethylene ester, 1.5kg lauryl amidopropyl betaine, 1.5kg polyoxyethylene alkanolamide, 0.45kg cationic quaternary ammonium salt, 0.45kg water-based polyethylene to the premixed solution in sequence Wax emulsion, 1.5kg chitosan, 0.75kg calendula extract, 0.75kg tannin, 0.1kg essence and 43kg deionized water were heated to 60°C at a heating rate of 2°C / min, and at a speed of 300r / min Stir for 80 minutes, and cool down to obtain the clothing care agent.

Embodiment 3

[0047] Embodiment 3: a kind of and nursing agent are prepared by the following method:

[0048] (1) Pre-mixing: Put 32.9kg deionized water, 5kg lauryl polyoxyethylene ether, and 5kg cocoyl glucoside into the batching kettle, heat it to 90°C at a heating rate of 7°C / min, and heat it at 500r / min Stir for 10min under the speed of rotation;

[0049] (2) Preparation: Add 7.5kg fatty acid polyoxyethylene ester, 3.75kg lauryl amidopropyl betaine, 3.75kg polyoxyethylene alkanolamide, 2kg cationic quaternary ammonium salt, 2kg water-based polyethylene wax to the premixed solution Emulsion, 2.5kg chitosan, 1.25kg calendula extract, 1.25kg tannin, 0.2kg essence and 32.9kg deionized water were heated to 70°C at a heating rate of 4°C / min, and at a speed of 400r / min Stir for 60 minutes, and cool down to obtain the clothing care agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com