Preparation method of anti-freezing waterproof adhesive for building

A building waterproof and adhesive technology, which is applied in the direction of adhesive type, polymer adhesive additive, non-polymer adhesive additive, etc., can solve the problem of poor waterproof performance, no adhesion of adhesive, The preparation method is complicated and other problems, and the effect of improving the application range and area, excellent waterproof performance and simple preparation method is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

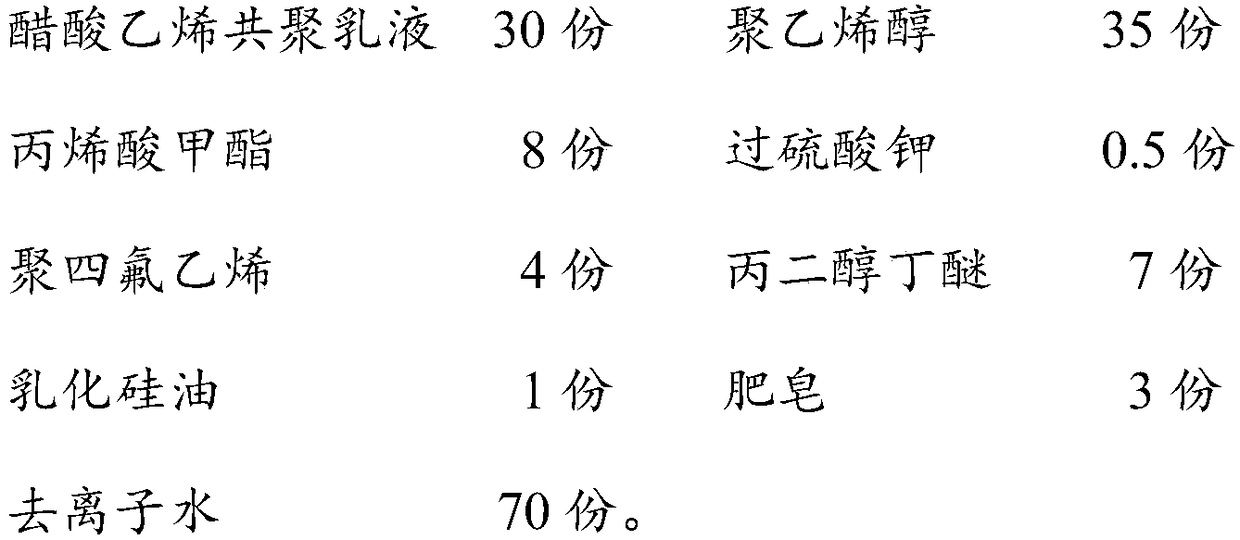

[0035] Freeze-resistant building waterproof adhesive, its raw material components in parts by mass are:

[0036]

[0037] Its preparation method is:

[0038] Weighing component quantities of vinyl acetate copolymer emulsion, polyvinyl alcohol, methyl acrylate, potassium persulfate, polytetrafluoroethylene, propylene glycol butyl ether, emulsified silicone oil, soap and deionized water;

[0039] Add deionized water into the reaction kettle, and heat the reaction kettle at a rate of 3°C / min, raise the temperature to 80°C, and turn on reflux condensation;

[0040] Add polyvinyl alcohol to the reaction kettle, turn on the stirrer, and the stirring speed is 180r / min, until it is completely dissolved;

[0041] Add vinyl acetate copolymer emulsion, polyvinyl alcohol and methyl acrylate to the reaction kettle, adjust the stirring speed to 450r / min, after stirring for 4 minutes, add polytetrafluoroethylene, soap and emulsified silicone oil, and stir evenly;

[0042] Add potassium ...

Embodiment 2

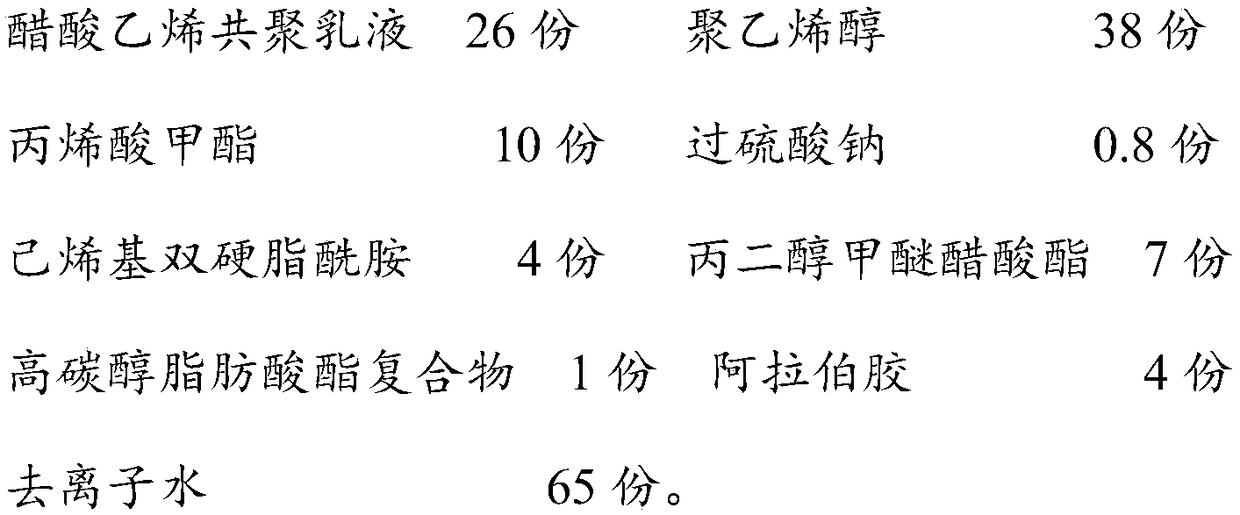

[0046] Freeze-resistant building waterproof adhesive, its raw material components in parts by mass are:

[0047]

[0048] Its preparation method is:

[0049] Weigh the components of vinyl acetate copolymer emulsion, polyvinyl alcohol, methyl acrylate, sodium persulfate, hexenyl bis stearamide, propylene glycol methyl ether acetate, higher alcohol fatty acid ester complex, gum arabic and deionized water;

[0050] Add deionized water into the reaction kettle, and heat the reaction kettle at a rate of 4°C / min, raise the temperature to 77°C, and turn on reflux condensation;

[0051] Add polyvinyl alcohol to the reaction kettle, turn on the stirrer, and the stirring speed is 210r / min, until it is completely dissolved;

[0052] Add vinyl acetate copolymer emulsion, polyvinyl alcohol and methyl acrylate to the reaction kettle, adjust the stirring speed to 430r / min, after stirring for 7 minutes, add hexenyl bis stearamide, gum arabic and higher alcohol fatty acid ester compound,...

Embodiment 3

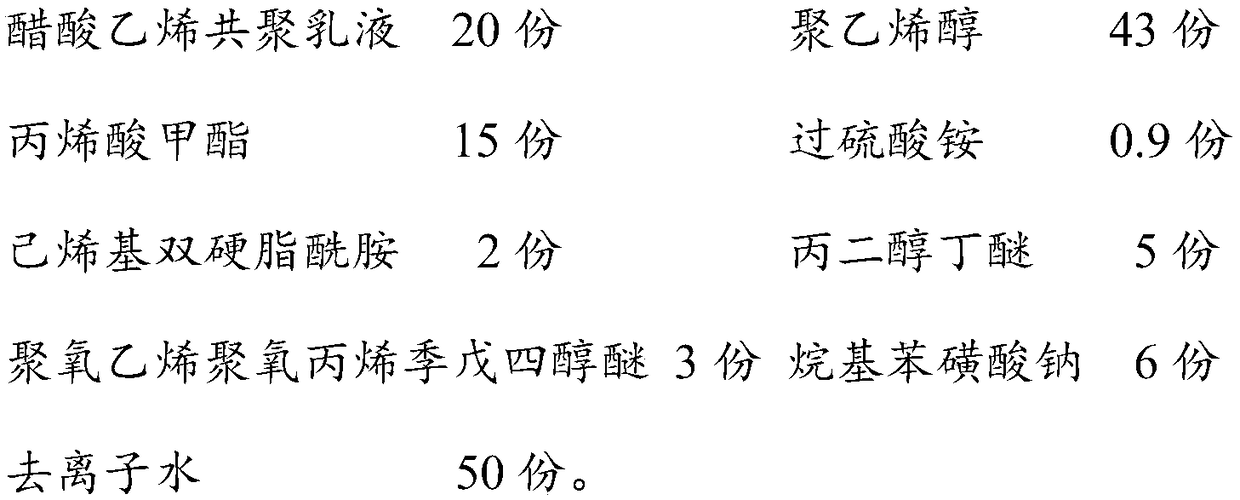

[0057] Freeze-resistant building waterproof adhesive, its raw material components in parts by mass are:

[0058]

[0059] Its preparation method is:

[0060] Vinyl acetate copolymer emulsion, polyvinyl alcohol, methyl acrylate, ammonium persulfate, hexenyl bis stearamide, propylene glycol butyl ether, polyoxyethylene polyoxypropylene pentaerythritol ether, sodium alkylbenzene sulfonate and Deionized water;

[0061] Add deionized water into the reaction kettle, and heat the reaction kettle at a rate of 6°C / min, raise the temperature to 70°C, and turn on reflux condensation;

[0062] Add polyvinyl alcohol to the reaction kettle, turn on the stirrer, and the stirring speed is 300r / min, until it is completely dissolved;

[0063] Add vinyl acetate copolymer emulsion, polyvinyl alcohol and methyl acrylate to the reaction kettle, adjust the stirring speed to 320r / min, and after stirring for 8 minutes, add hexenylbisstearamide, sodium alkylbenzenesulfonate and polyoxygen Ethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com