An ultra-low glass transition temperature organosilicon special optical fiber inner layer coating and preparation method thereof

A glass transition temperature, special optical fiber technology, applied in conductive coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve problems such as optical performance decline, dynamic fatigue parameter Nd value decline, and optical fiber overall performance decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

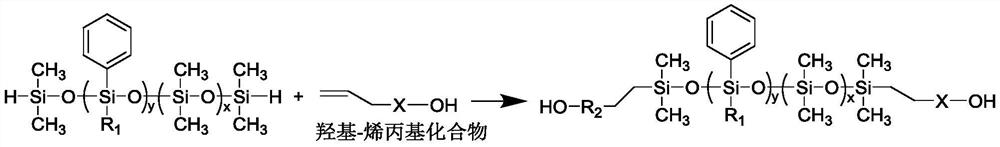

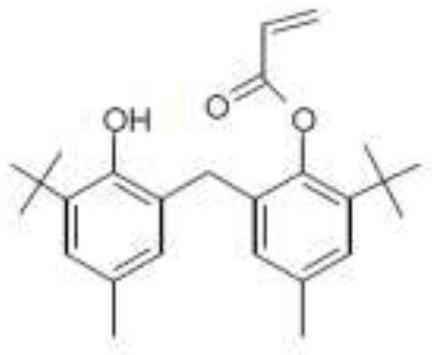

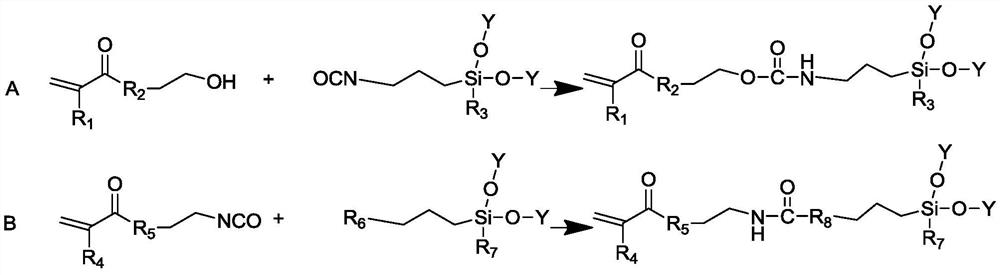

Method used

Image

Examples

Embodiment 1

[0061] An ultra-low glass transition temperature organosilicon special optical fiber inner layer coating, the content of each component is: organosilicon prepolymer 70%, additives 2%, photoinitiator 4%, low temperature active monomer Body 16%, interface activated resin 8%.

[0062] The organosilicon prepolymer is the PUA-PP1 synthesized above.

[0063] The composition of the auxiliary agent is calculated by weight percentage: its component content is 80% of antioxidant CHINOXGM, 10% of polymerization inhibitor p-methoxyphenol, and 10% of antistatic agent SN.

[0064] The composition of the photoinitiator by weight percentage is: 50% photoinitiator TPO, 30% photoinitiator 184, and 20% photoinitiator 819.

[0065] The composition of the low-temperature active monomer is calculated by weight percentage: 10% lauryl methacrylate, 90% heptadecyl acrylate.

[0066] The interface-active resin is J-1 synthesized above.

[0067] The preparation method of the above-mentioned ultra-low...

Embodiment 2

[0073] An ultra-low glass transition temperature organosilicon special optical fiber inner layer coating, the content of each component is: organosilicon prepolymer 60%, auxiliary agent 2.5%, photoinitiator 3.5%, low temperature active monomer Body 31%, interface activation resin 3%.

[0074] The composition of the organosilicon prepolymer by weight percentage is: 30% PUA-PP1, 70% PUA-PP2.

[0075] The composition of the auxiliary agent is calculated by weight percentage: its component content is 80% of antioxidant CHINOXGM, 10% of polymerization inhibitor hydroquinone, and 10% of defoamer BYK-1790.

[0076] The composition of the photoinitiator by weight percentage is: 70% photoinitiator TPO, 30% photoinitiator 907.

[0077] The composition of the low-temperature active monomer is calculated by weight percentage: 10% lauryl methacrylate, 10% heptadecyl acrylate, and 80% isocecyl acrylate.

[0078] The interface-active resin is J-2 synthesized above.

[0079] The preparation ...

Embodiment 3

[0085] An ultra-low glass transition temperature organosilicon special optical fiber inner layer coating, the content of its components is as follows: organosilicon prepolymer 65%, additives 1.7%, photoinitiator 4.5%, low temperature active monomer Body 23.8%, interface activation resin 5%.

[0086] The composition of the organosilicon prepolymer by weight percentage is: 100% PUA-PP2.

[0087] The composition of the auxiliary agent is calculated by weight percentage: its component content is 90% of antioxidant CHINOXGM, and 10% of polymerization inhibitor 2,6-di-tert-butyl-4-methylphenol.

[0088] The composition of the photoinitiator by weight percentage is: 70% photoinitiator 819, 30% photoinitiator 184.

[0089] The composition of the low-temperature active monomer is calculated by weight percentage: 10% lauryl methacrylate, 85% isotridecyl acrylate, and 5% isocecyl acrylate.

[0090] The interface-active resin is J-2 synthesized above.

[0091] The preparation method of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com