A kind of preparation method of damping bush rubber material

A technology of shock-absorbing bushings and rubber materials, applied in the direction of coating, etc., can solve the problems of poor support of shock-absorbing bushings, complicated disassembly and installation of shock-absorbing bushings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

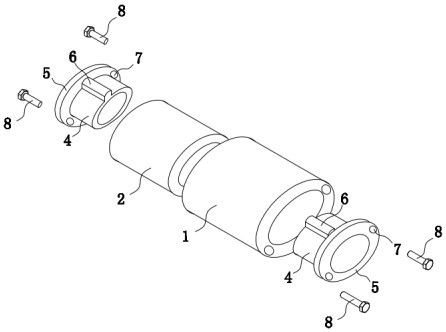

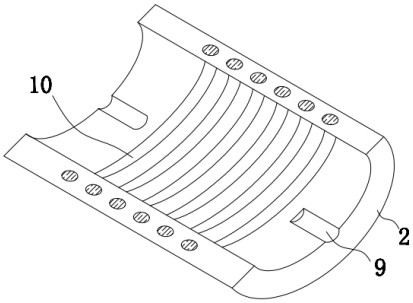

[0026] The present invention provides such Figure 1-2 A method for preparing a shock-absorbing bush rubber material, comprising a rubber bush body 2, the rubber bush body 2 is injection-molded with a rubber material to form a spiral support frame 10, and the parts by weight of each component of the rubber material are as follows of: 10 parts of chlorosulfonated polyethylene, 5 parts of active agent, 3 parts of tackifying resin, 20 parts of carbon black, 15 parts of softener, 20 parts of reinforcing agent, 6 parts of ethoxyquinoline and 1 part of accelerator, Specifically include the following steps:

[0027] S1. Internal mixer mixing

[0028] After raising the temperature of the internal mixer to 50-80°C, put in chlorosulfonated polyethylene, stir to make the chlorosulfonated polyethylene soften and uniform, add the active agent, stir to make the active agent uniformly dispersed in the chlorosulfonated polyethylene, Then add carbon black, softener, reinforcing agent, ethoxy...

Embodiment 2

[0038] A method for preparing a rubber material for a shock-absorbing bushing, comprising a rubber bushing body, the rubber bushing body is injection-molded with a rubber material to form a spiral support frame, and the parts by weight of each component of the rubber material are as follows: chlorosulfur 15 parts of polyethylene, 10 parts of active agent, 3 parts of tackifying resin, 20 parts of carbon black, 5 parts of softening agent, 25 parts of reinforcing agent, 6 parts of ethoxyquinoline and 4 parts of accelerator, specifically include the following steps :

[0039] S1. Internal mixer mixing

[0040] After raising the temperature of the internal mixer to 50-80°C, put in chlorosulfonated polyethylene, stir to make the chlorosulfonated polyethylene soften and uniform, add the active agent, stir to make the active agent uniformly dispersed in the chlorosulfonated polyethylene, Then add carbon black, softener, reinforcing agent, ethoxyquinoline, tackifying resin and acceler...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com