Anisotropic heat and electricity-conductive polymer composite material and preparation method thereof

A technology of electrical and thermal conductivity, composite materials, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of high processing conditions, high injection speed (high energy consumption, complex microstructure design, etc., to achieve the effect of enhanced shearing)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0040] (1) Melt-blending the graphene nanoplatelet (GNP) and the polymer using a torque rheometer to ensure that the GNP is uniformly dispersed in the polymer, thereby preparing the polymer / GNP blend raw material; wherein, The mixing temperature of the torque rheometer is set to: 180-220°C;

[0041] (2) Ultra-high-speed pulverization of the blend raw material prepared in step (1) at room temperature, so that the polymer / GNP blend raw material is broken from a block into a polymer / GNP blend with a size of 80-500 mesh pellets for multi-melt multiple injection molding;

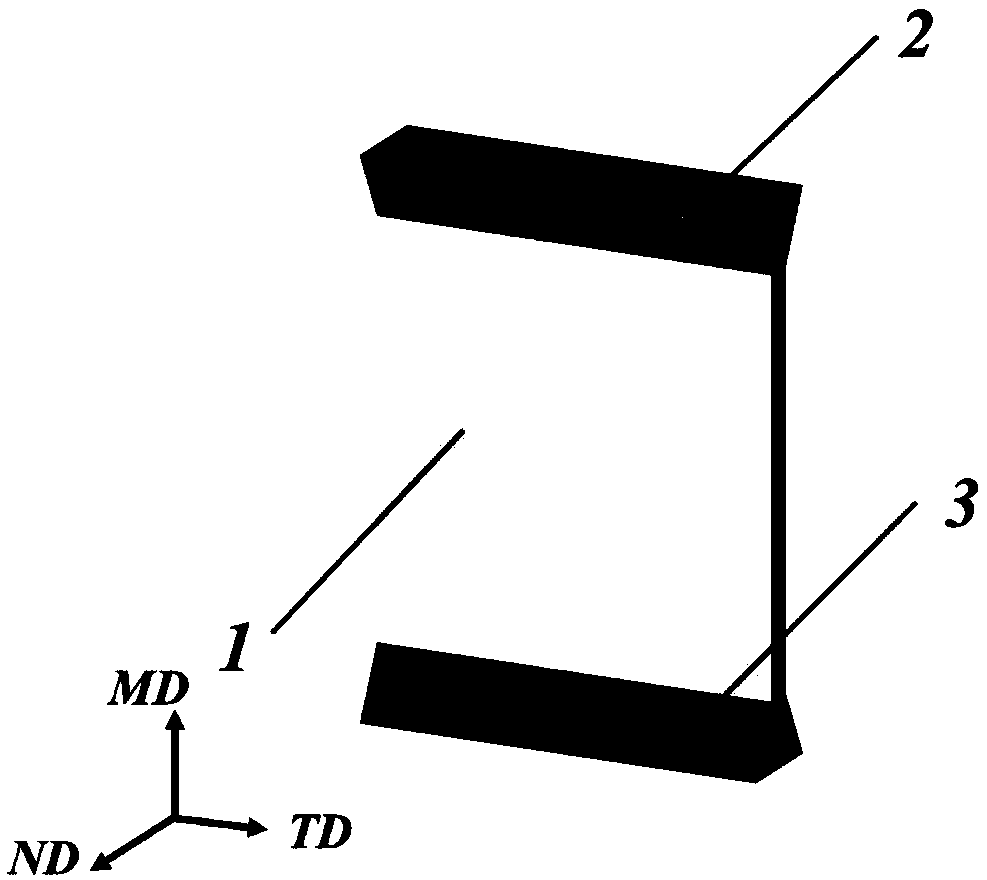

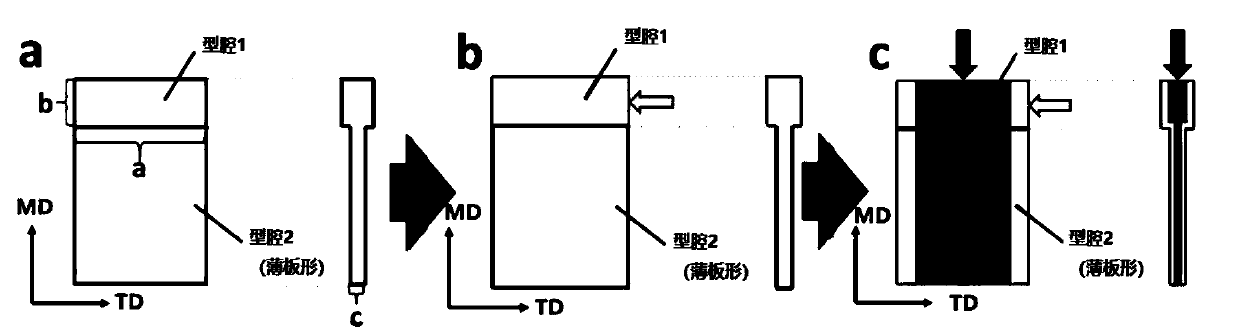

[0042] (3) The anisotropic polymer / GNP composite material with planar orientation GNP structure is prepared by multi-melt multiple injection molding, and a multi-melt injection mold cavity is adopted, and the multi-melt injection mold cavity has a main body Cavity 1, a drainage cavity 2 communicating with the main cavity is arranged above the main cavity; the thickness of the main cavity 1 is 1 mm, and the thick...

Embodiment 1

[0048] Isotactic polypropylene (iPP, grade PPH-T03, produced by China Maoming Petrochemical Company) and graphene nanoplatelets (Graphene nanoplatelet, GNP, grade GT-G03, produced by Xiamen Kaina Graphene Technology Co., Ltd., with a diameter of 5-20 μm , thickness 1-5nm) was added to the torque rheometer according to the mass ratio of 75:25 for blending, so that the GNP was uniformly dispersed in the PP matrix to obtain the blend raw material; then it was crushed at room temperature by a high-speed crushing device to obtain PP / GNP blend particles; finally, the PP / GNP composite material is prepared by multi-melt multiple injection molding. The cavity parameters and the specific molding process are:

[0049] (1) if figure 2 As shown in (a), the main cavity is designed as a thin-plate-shaped special-shaped cavity with variable cross-section, which is composed of cavity 1 and cavity 2, in which the drainage cavity 2 is rectangular on TD, the main cavity 1 is a thin plate, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com