Premodulation technology for concentrated advanced treatment of sludge

An advanced treatment and pre-conditioning technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of thick and difficult sludge treatment, and reduce the interface Tension, effects that increase mixing, increase shear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

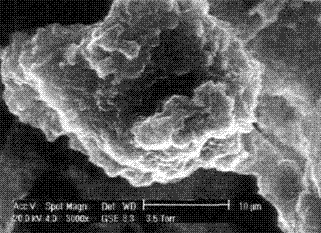

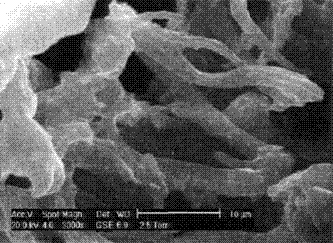

Image

Examples

Embodiment 1

[0029] Import 6,776kg of municipal sludge with a water content of 79% and an organic matter content of 33% into the conditioning tank, add 285 liters of polyaluminum sulfate with a concentration of 5% (the weight ratio is 1% of the absolute dry sludge), add water to dilute to a water content of 97%, and at the same time Turn on the cutting and crushing mixer (300r / min), stir for 10min, and introduce it into the photocatalytic oxidation tank through the screw pump, and then add the loaded TiO in the reaction tank 2 Photocatalyst 75kg, after stirring for 5 minutes, turn on the ultraviolet generator to irradiate the sludge in the reactor, and at the same time, introduce high-energy electrons through the aeration pipeline through the high-energy electron generator to react, and react for 50 minutes while stirring. Then add composite coagulant (PAC13.8kg, PAM1.80kg) through the dispensing tank, and after 5 minutes, discharge the supernatant in the reaction tank into the drainage sys...

Embodiment 2

[0031]Import 7035kg of municipal sludge with 80% water content and 36% organic matter content into the preparation tank, add 150 liters of polyaluminum sulfate with a concentration of 5% (0.5% by weight of the absolute dry sludge), dilute with water to 99% water content, and at the same time Turn on the cutting and crushing mixer (300r / min), stir for 5 minutes, and introduce the photocatalytic oxidation tank through the screw pump, and then add the loaded TiO in the reaction tank 2 The photocatalyst was 76.02 kg. After stirring for 5 minutes, the ultraviolet generator was turned on to irradiate the sludge in the reactor. At the same time, high-energy electrons were introduced through the aeration pipeline through the high-energy electron generator to react, and the reaction was carried out for 60 minutes while stirring. Then add composite coagulant (PAC15.00kg, PAM1.82kg) through the dispensing tank, and after 5 minutes, discharge the supernatant in the reaction tank into the d...

Embodiment 3

[0033] 9430kg of printing and dyeing sludge with a water content of 83% and an organic matter content of 36% was introduced into the preparation tank, and 320 liters of polyaluminum sulfate was added at a concentration of 25% (the weight ratio was 5% of the dry sludge), diluted with water to a water content of 97%, and added Sodium tripolyphosphate 8.25kg (the weight ratio is 5‰ of the absolute dry sludge), at the same time start the cutting and crushing mixer, stir for 15min, enter the photoelectric catalytic oxidation tank through the screw pump, and then add the loaded TiO in the reaction tank 2 The photocatalyst was 86.5 kg. After stirring for 5 minutes, the ultraviolet generator was turned on to irradiate the sludge in the reactor. At the same time, the high-energy electrons were introduced into the reactor through the high-energy electron generator through the aeration pipeline for reaction, and the reaction was carried out for 30 minutes while stirring. Then add composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com