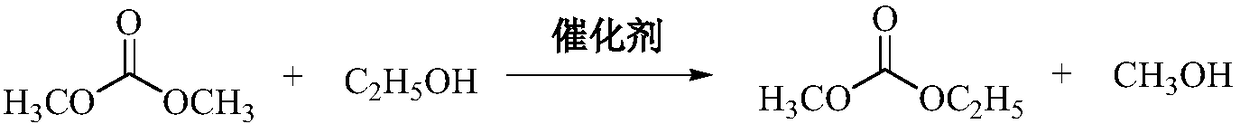

Method for preparing methyl ethyl carbonate through transesterification of dimethyl carbonate and ethyl alcohol

A technology of ethyl methyl carbonate and dimethyl carbonate, which is applied in the field of preparing ethyl methyl carbonate by transesterification of dimethyl carbonate and ethanol, can solve the problems of low selectivity of the product ethyl methyl carbonate, large amount of catalyst and raw materials. Low conversion rate and other problems, to achieve the effects of low raw material toxicity, low pollution, and no corrosion dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

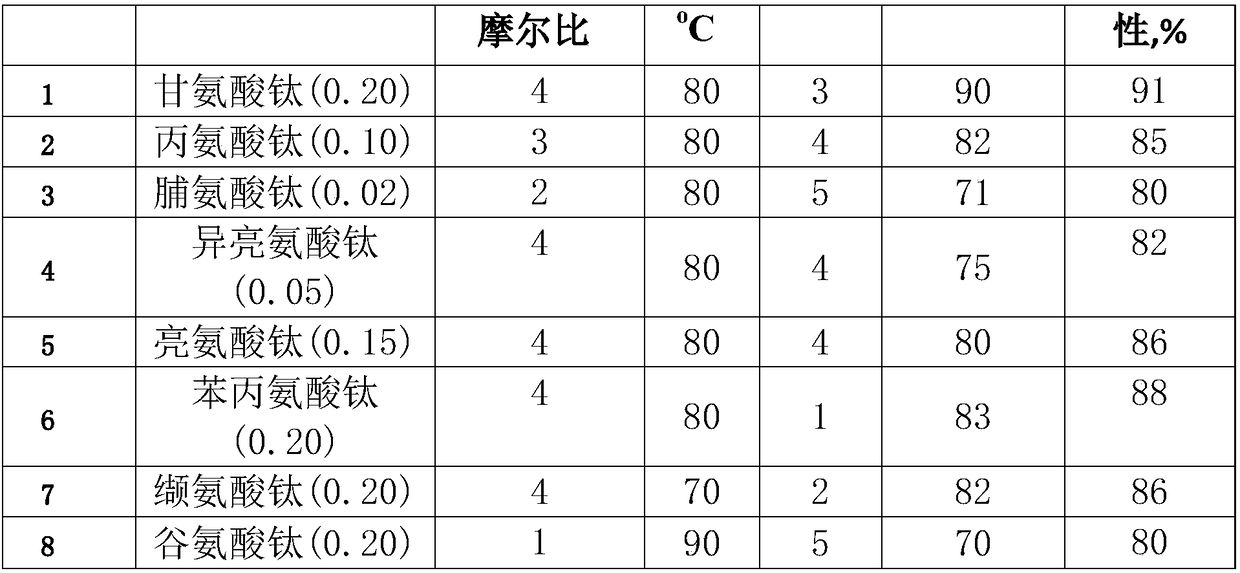

Embodiment 1

[0022] Add 9.0 grams of dimethyl carbonate (Dimethyl Carbonate, DMC for short, 0.1 mol), 18.4 grams of ethanol (0.4 mol), 0.02 grams of titanium glycinate (0.2% of the mass of dimethyl carbonate) into 100 ml of two round tubes equipped with condenser tubes In the bottom flask, stir evenly, be warming up to 80 ℃ and react for 3 hours, the mixture after the reaction is carried out qualitative and quantitative analysis by gas chromatography-mass spectrometry, and the conversion rate of dimethyl carbonate is 90%, ethyl methyl carbonate (Ethyl Methyl Carbonate, EMC for short) selectivity is 91%.

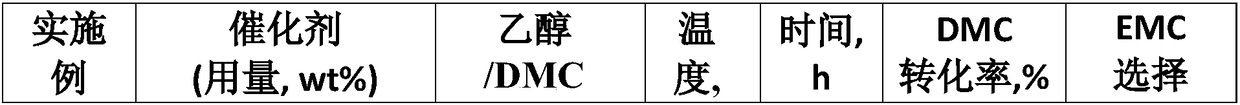

Embodiment 2~8

[0024] The specific methods of Examples 2-8 are similar to those of Example 1, and the specific reaction conditions and results are shown in Table 1. Titanium alanine, titanium proline, titanium isoleucine, titanium leucine, titanium phenylalanine, titanium valine, titanium glutamate are used as catalysts, and the molar ratio of ethanol to dimethyl carbonate is 1 ~4, the reaction temperature is 70~90°C, the reaction time is 1~5 hours, the DMC conversion rate reaches more than 70%, and the EMC selectivity reaches more than 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com