A preparation method of cobaltous oxide nanocrystals and cobaltous oxide nanocrystals prepared therefrom

A technology of cobaltous oxide nanometer and cobalt salt, which is applied in the direction of cobalt oxide/cobalt hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of uneven crystal grains, impurities mixed in, and low crystallinity, and achieve uniform particle size distribution, Avoid the mixing of impurities and the effect of complete grain development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

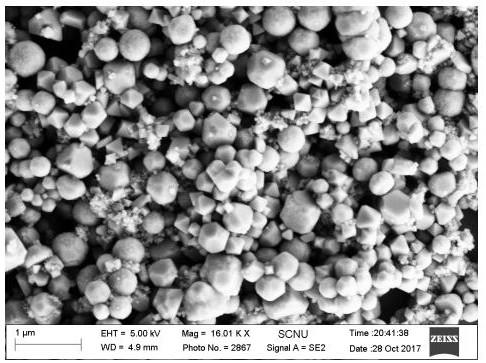

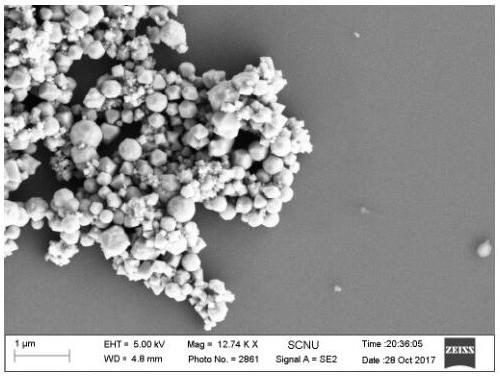

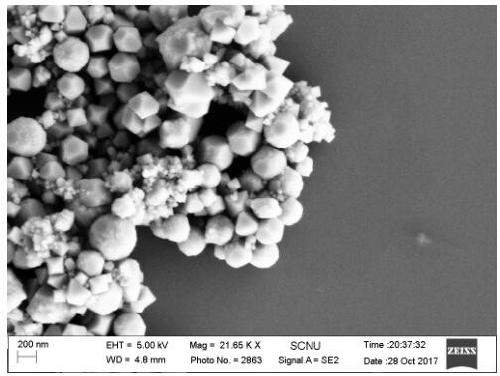

[0027] A method for preparing cobaltous oxide nanocrystals, using cobalt acetate tetrahydrate (purity 99.5%) and triphenylphosphine (purity 98%) as precursors, completely dissolving the precursors in oleylamine, and reacting in a closed environment 18h, the reaction temperature is 180°C, and the heating rate is 10°C / min. Pour the hydrothermal reaction mixture into a centrifuge tube, centrifuge at 5000r / min for 5min, then wash and centrifuge twice with absolute ethanol, and dry at 60°C to obtain oxidation Subcobaltous nanocrystals, wherein the mass ratio of cobalt acetate tetrahydrate and triphenylphosphine is 1:10, and the consumption of oleylamine is 35mL.

Embodiment 2

[0029] A method for preparing cobaltous oxide nanocrystals, using cobalt acetate tetrahydrate (purity 99.5%) and triphenylphosphine (purity 98%) as precursors, completely dissolving the precursors in oleylamine, and reacting in a closed environment 18h, the reaction temperature is 180°C, and the heating rate is 10°C / min. Pour the hydrothermal reaction mixture into a centrifuge tube, centrifuge at 5000r / min for 5min, then wash and centrifuge twice with absolute ethanol, and dry at 60°C to obtain oxidation Subcobaltous nanocrystals, wherein the mass ratio of cobalt acetate tetrahydrate and triphenylphosphine is 1:20, and the consumption of oleylamine is 35mL.

Embodiment 3

[0031] A method for preparing cobaltous oxide nanocrystals, using cobalt acetate tetrahydrate (purity 99.5%) and triphenylphosphine (purity 98%) as precursors, completely dissolving the precursors in oleylamine, and reacting in a closed environment 18h, the reaction temperature is 180°C, and the heating rate is 10°C / min. Pour the hydrothermal reaction mixture into a centrifuge tube, centrifuge at 5000r / min for 5min, then wash and centrifuge twice with absolute ethanol, and dry at 60°C to obtain oxidation Subcobaltous nanocrystals, wherein the mass ratio of cobalt acetate tetrahydrate and triphenylphosphine is 1:25, and the consumption of oleylamine is 35mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com