Clean and efficient production line for sauce

A production line and sauce technology, applied in multiple packaging, packaging, food science, etc., can solve the problems of oil pollution in the production and processing environment, hidden dangers of food production safety, low efficiency, etc., to achieve automation and intelligent operation, shorten length and packaging takt time, and the effect of reducing the number of operating staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

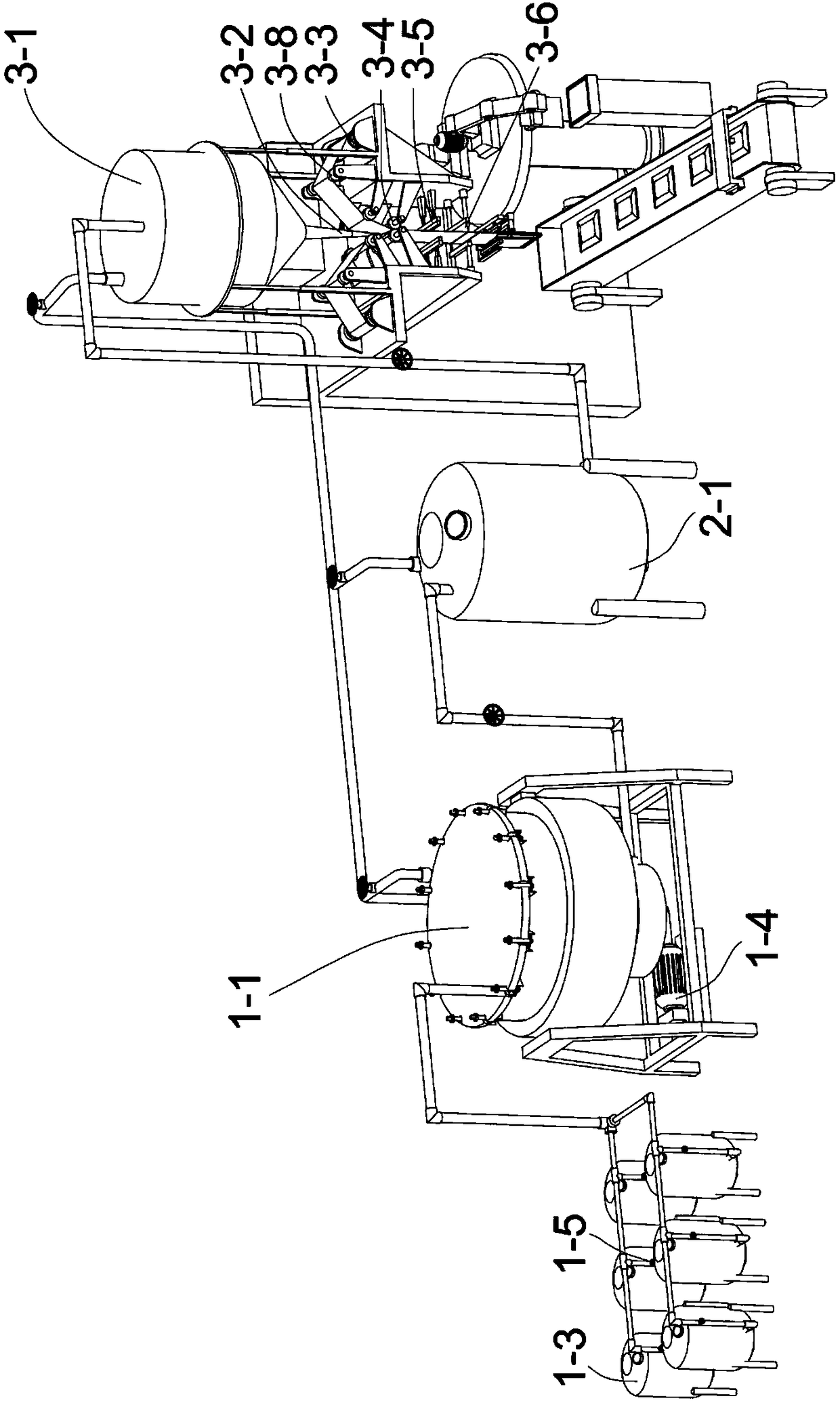

[0018] Such as Figure 1 to Figure 6 As shown, a clean and efficient production line for sauces. The processing steps of the production line include: frying process, cooling process, and packaging process. The equipment and structure of each process are as follows:

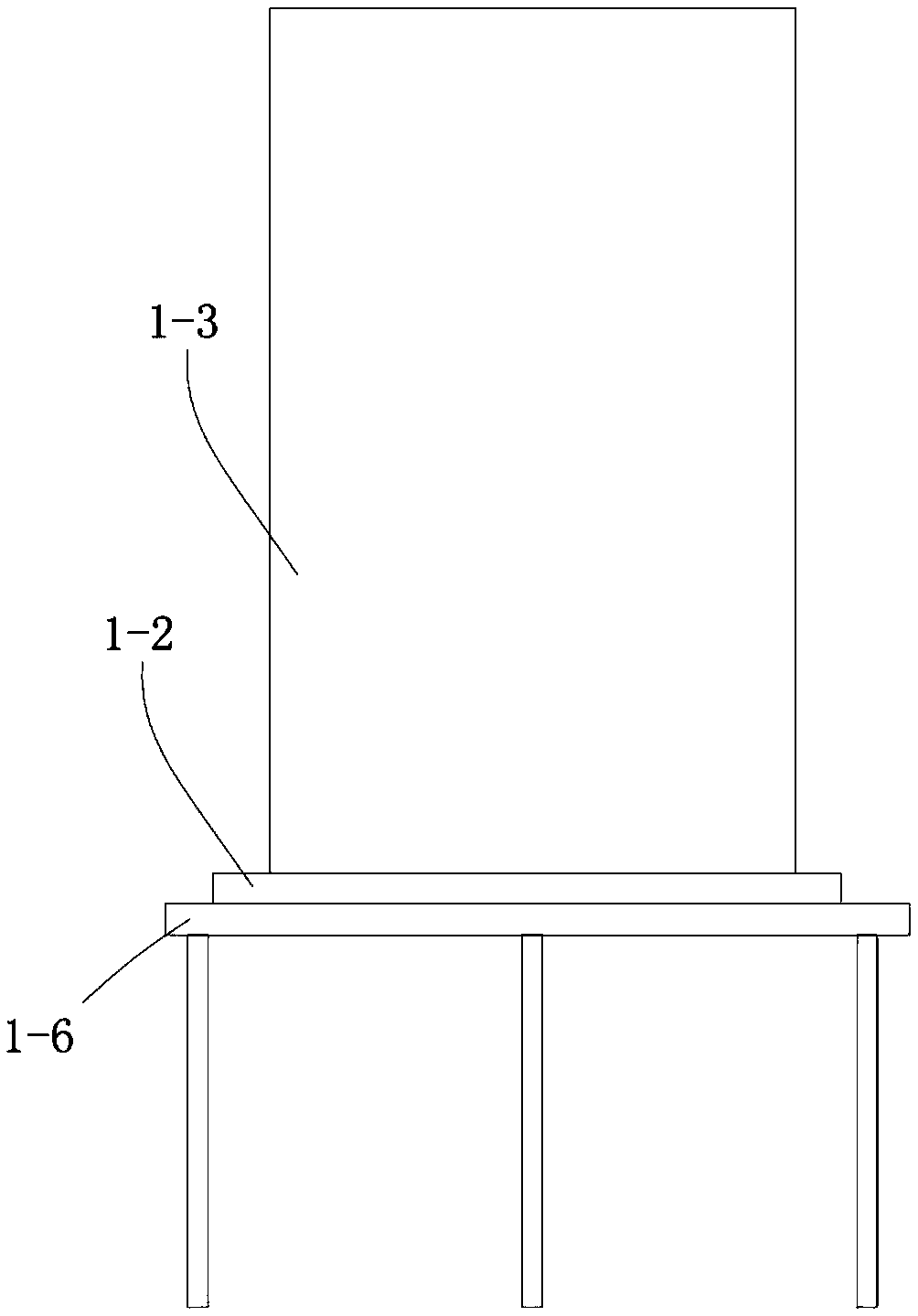

[0019] The device of the frying process includes: an automatic stir-frying electric frying pan 1-1, placed on the top of the electronic scale 1-2, and a batching tank 1-3 connected to the automatic stirring electric frying pan 1-1 through pipelines, and an electronic scale The quantity of the batching tank is the same as the type of raw and auxiliary materials used in the production of sauce, and the air pump 1-4 connected with the automatic stir-frying electric frying pan 1-1 is used to extract the air in the automatic stirring electric frying pan to make the automatic stirring electric frying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com