Multi-pollutant cooperative control system for flue gas and water collection technology thereof

A technology for collaborative control and pollutants, applied in the direction of gas treatment, climate sustainability, greenhouse gas reduction, etc., to achieve the effect of reducing specific heat, improving governance level, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

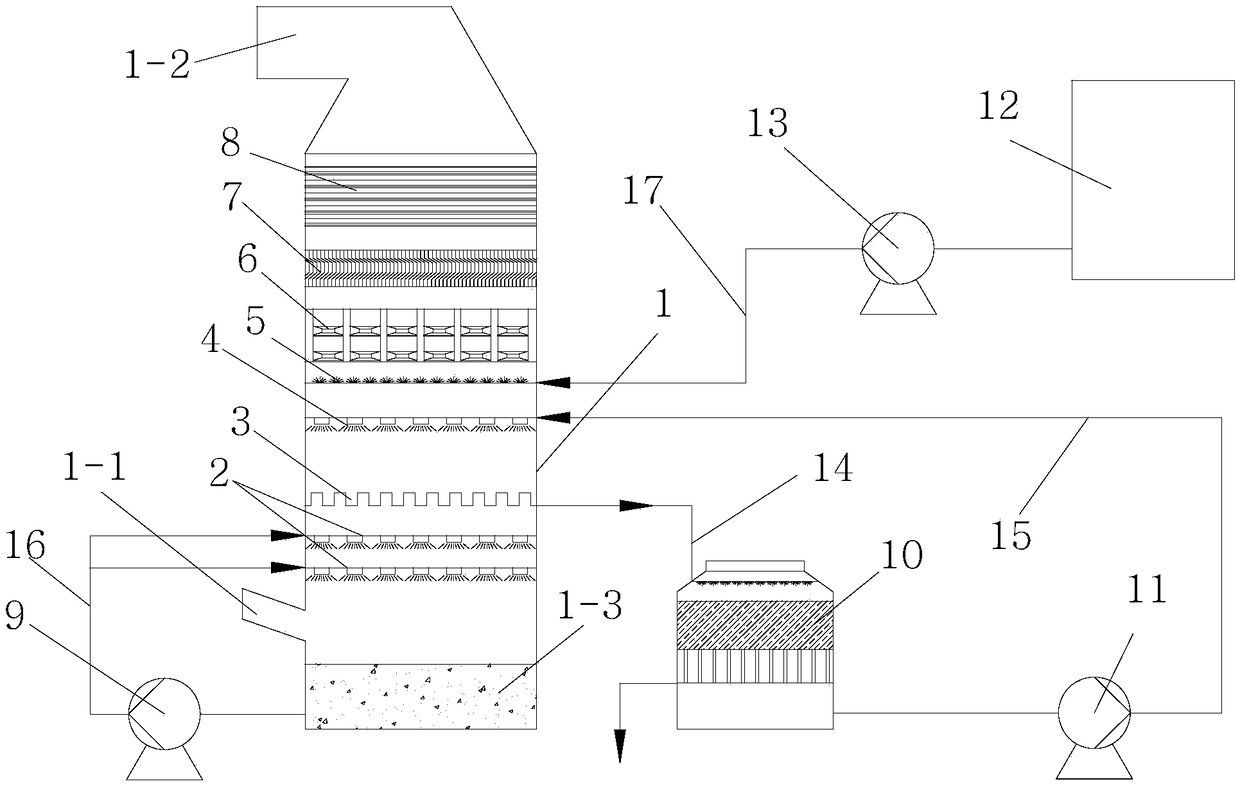

[0020] Embodiment 1: refer to figure 1 . A flue gas multi-pollutant cooperative control system, including a desulfurization tower 1 with a flue inside, and in the desulfurization tower 1, from bottom to top, at least one set of desulfurization spray layer 2, cooling liquid accumulation layer 3, and cooling spray Layer 4, mist eliminator, flue gas heat exchange layer 8; a smoke inlet 1-1 is arranged on the side wall of the lower end of the desulfurization tower 1, and a smoke outlet 1-2 is arranged on the top or the top side of the desulfurization tower 1. A desulfurization circulation pump 9, a circulating fluid cooling tower 10, a condensation cooling circulation pump 11, and a demister flushing pump 13 are provided outside the desulfurization tower 1. The other end of the pipeline 14 is connected to the liquid return port of the circulating liquid cooling tower 10, and the liquid outlet at the bottom of the circulating liquid cooling tower 10 is connected to the liquid supp...

Embodiment 2

[0031] Embodiment 2: refer to figure 1 . A water collection method for a flue gas multi-pollutant collaborative control system, comprising the following process steps through the flue gas multi-pollutant collaborative control system:

[0032] 1) The sulfur-containing flue gas enters the absorption tower 1 from the inlet flue, and performs a reverse contact reaction with the desulfurization liquid sprayed from the desulfurization spray layer 2 to remove most of the SO in the original flue gas 2 , HF, HC l Such as acid gas and dust particles, the flue gas is cooled to 50°C-60°C and reaches saturation;

[0033] 2) The high-humidity saturated flue gas containing many pollutants flows upward into the cooling condensation layer, and conducts reverse contact and heat exchange with the circulating slurry in the lower temperature cooling spray layer 4. The temperature of the flue gas drops to 30-45°C, and the saturated steam Cooling and condensing, a large amount of water vapor and ...

Embodiment 3

[0038] Example 3. In a thermal power plant, the flue gas desulfurization renovation project of a 300WM unit adopts this process. The SO2 concentration in the inlet flue gas is 2239mg / m3, the dust concentration in the inlet flue gas is 45mg / m3, and the liquid-gas ratio of the cooling spray layer circulating fluid is 2.3 L / Nm3, the coverage rate of the spray layer is 200%, the gas-liquid contact time is 1.2s, the flue gas cooling range is 13°C, the height of the liquid accumulation layer from the top desulfurization spray layer is 0.5, and the distance between the liquid accumulation layer and the cooling spray layer The distance of the demister is 2m, the preparation pressure of the ultra-fine atomization nozzle for flushing the spray layer of the mist eliminator is 0.12MPa, the flushing liquid-gas ratio is 0.05L / Nm3, and the flue gas cooling range is 1.8°C. The SO2 concentration in the outlet flue gas is 2.7mg / m3, the dust concentration in the outlet flue gas is 0.6mg / m3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com