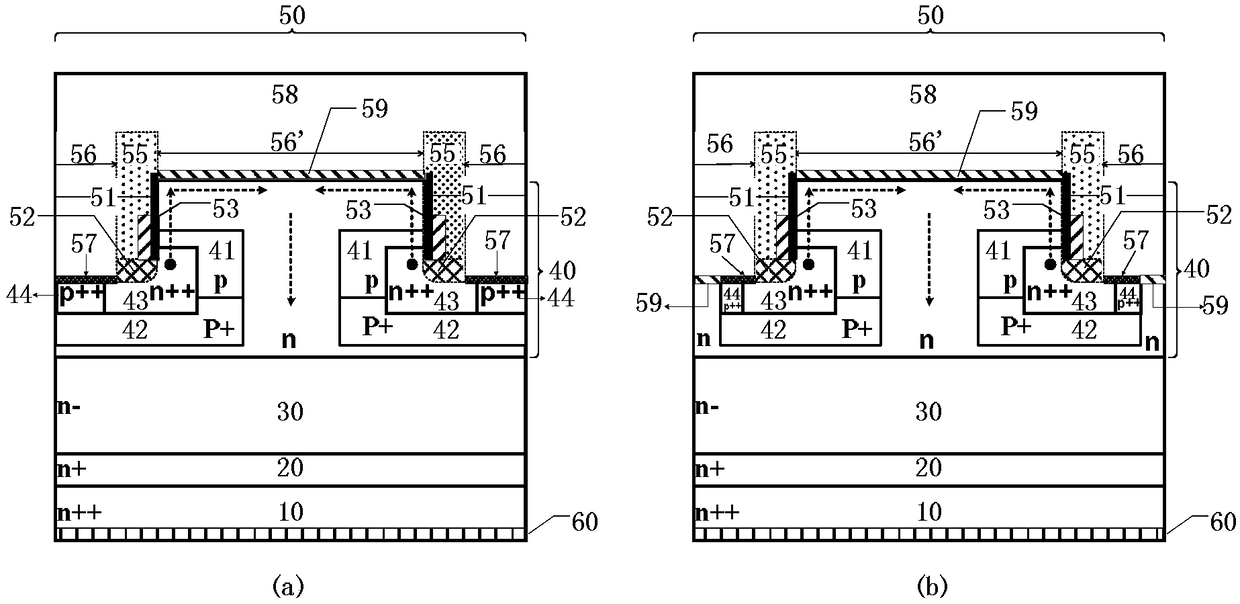

Silicon carbide trench type MOSFETs integrated with SBD and preparation method thereof

A silicon carbide trench and silicon carbide substrate technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as excessive electric field, achieve small Le charge, reduce overlapping area, and improve carrier migration rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0109] figure 2 It is a schematic diagram of the steps of the preparation method, such as figure 2 Shown, described preparation method comprises:

[0110] Step A: making a silicon carbide epitaxial wafer substrate; including, sequentially growing an n+ type buffer layer 20, an n-drift layer 30 and an n-type current transport layer 40 on an n++ type silicon carbide substrate 10 from bottom to top, as image 3 shown;

[0111] Step B: Doping the active region in the n-type current transport layer 40, including:

[0112] method 1)

[0113] Sub-step B1: Deposit an implantation mask on the n-type current transport layer 40, pattern it by photolithography, and use doping methods such as ion implantation to form a top-down p-type trench in the n-type current transport layer 40 channel layer 41 and p+ type shielding layer 42, such as Figure 4 shown;

[0114] In the sub-step B1, the doping concentration range of the p-type channel layer 41 is 1×10 16 cm -3 ~1×10 18 cm -3 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com