R-type discharge coil

A technology of discharge coils and iron cores, applied in the direction of coils, circuits, electrical components, etc., can solve the problems of low mechanical bearing capacity, high noise, violent vibration of iron cores, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

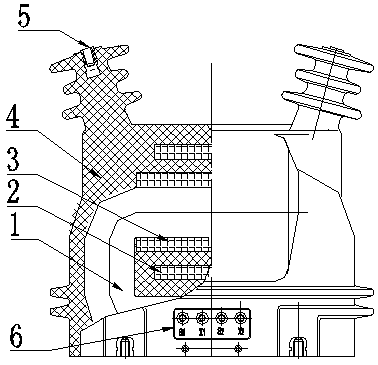

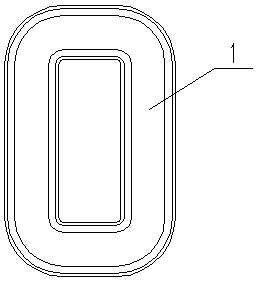

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings. An R-shaped discharge coil mainly includes an R-shaped iron core 1, a primary winding 2, a secondary winding 3, a high-voltage terminal 5, a low-voltage terminal 6, and epoxy resin 4. The primary winding 2 and the secondary winding 3 are made of F-grade QZY-155 copper enameled wire and wound with a special R-type winding machine; the secondary winding 3 is wound on an R-type iron core covered with insulation 1, the primary winding 2 is wound on the epoxy skeleton; the primary winding 2 is connected to the high-voltage terminal 5, and the secondary winding 3 is connected to the low-voltage terminal 6; The key to the structure is that the R-shaped iron core 1 is formed by winding a whole continuous and uninterrupted strip of oriented silicon steel sheet on a special mould.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com