Backlight unit used for local light adjustment and luminous flux control member

A technology for light beam control components and backlight units, which is applied to diffuse elements, optics, nonlinear optics, etc., can solve the problems of increasing the thickness of light guide components and the limitation of ultra-thin backlight unit thickness, and achieves the effect of preventing white spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

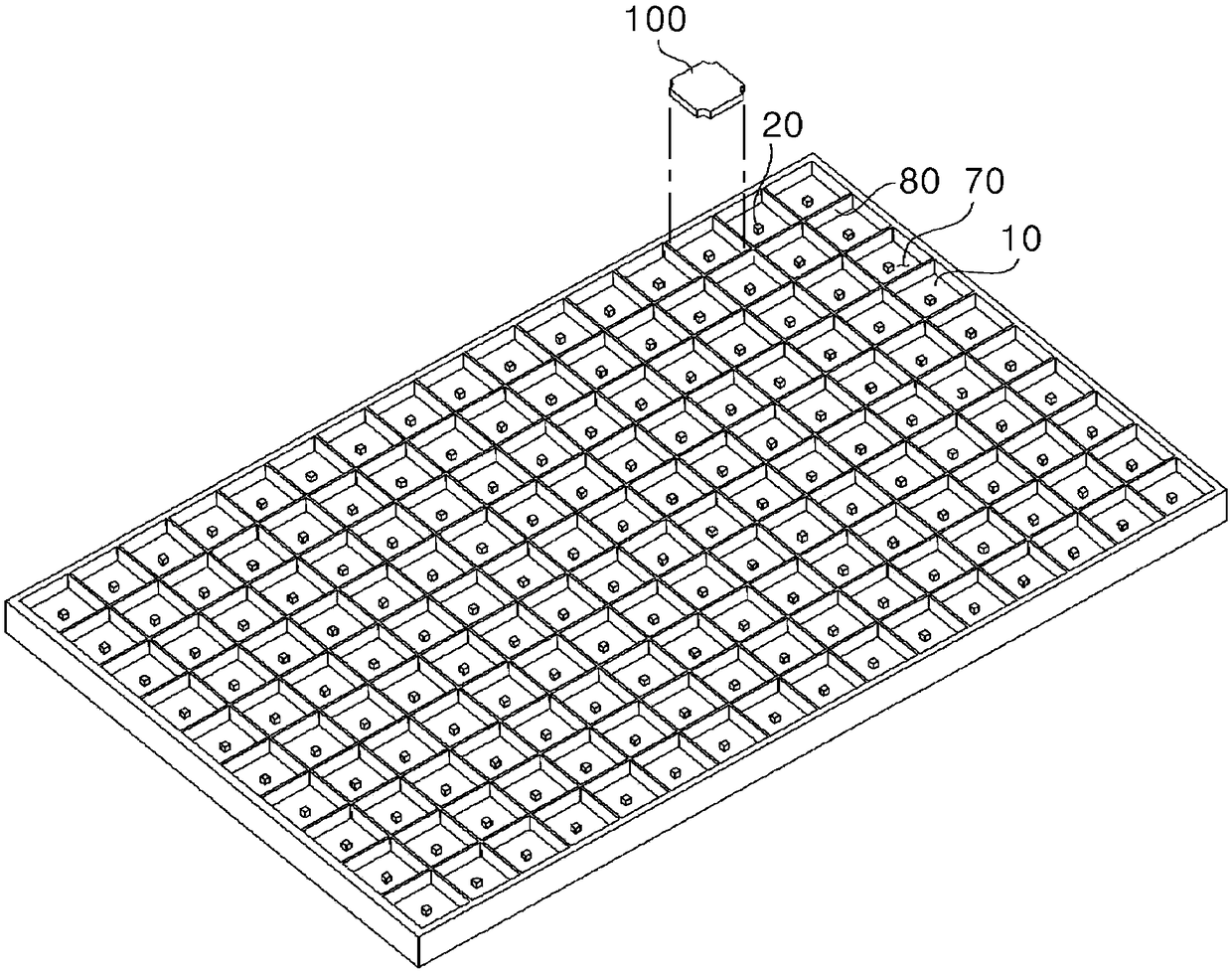

[0048] Figure 1a is a perspective view for explaining a backlight unit according to an embodiment of the present invention.

[0049] refer to Figure 1a Alternatively, the backlight unit may include a frame coupled behind the LCD display panel. The substrate 10 on which a plurality of light sources 20 are arranged is arranged on the frame. A light beam control component 100 corresponding to the light source 20 is disposed on the substrate 10 . The light beam control components 100 are arranged on the light source 20 one by one, and the light diverging from the light source can evenly diverge to the front of the backlight unit while passing through the light beam control components.

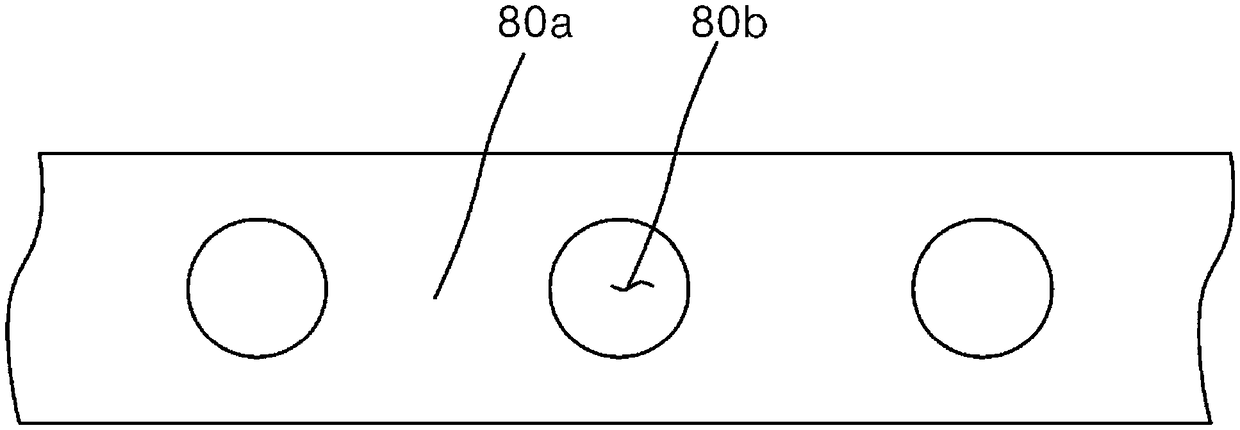

[0050] The substrate 10 is divided into a plurality of regions 70, and the light source 20 can be arranged in each region. Partition walls 80 are disposed on the substrate 10 to define the region 70 . The light flux control member 100 is arranged in each area 70 defined by the partition wall 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com