Testing apparatus and method capable of realizing impacting rock burst visualization observation

A test device and rockburst technology, which is applied in the field of engineering tests, can solve the problems of failure surface stress, strain, displacement invisible, etc., and achieve the effect of simple device and high operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

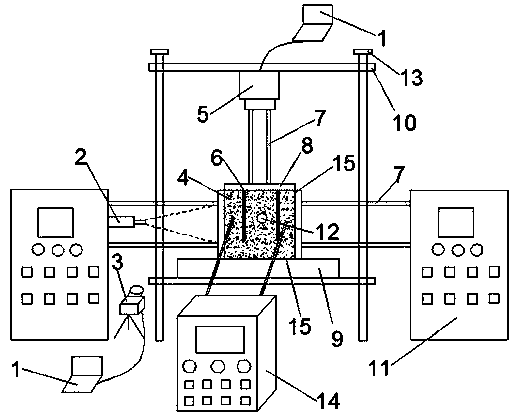

Embodiment 1

[0046]Step 1: Slowly pour the prepared mixture of mineral oil and silicon powder into the mold with a small spoon, and shake the mold lightly during the pouring process to make it evenly distributed. The mold is an open square, and the size of its inner wall is 250mm×250mm×250mm. Before the solid-liquid mixture has initial setting strength, insert one end of the thin steel sheet coated with vaseline into the solid-liquid mixture from the mold opening. After the molding is completed, use a vacuum pump to evacuate the transparent rock 4 test until there are no air bubbles on the surface of the sample. After standing in the laboratory for one day, slowly pull out the thin steel sheet, remove the formwork, and prepare the transparent rock 4 with the prefabricated structural surface 6 . The refractive index of transparent rock 4 in this example is 1.477. A drill bit with a diameter of 30 mm is selected to turn a hole in the center of the X-direction perpendicular to the transpare...

Embodiment 1

[0051] Embodiment 1 is to carry out the research of impact rock mass rockburst process under the unidirectional stress of transparent rock 4 gradually reduces, other two-directional stress is constant, and for the research of rock mass rockburst process under the bidirectional stress reduction, can be in the embodiment On the basis of 1, change the implementation of step 3. Control the hydraulic jack 5, the X-direction servo actuator 11, and the Y-direction servo actuator 14 through the computer 1 to slowly apply a three-dimensional stress of 100 MPa to the transparent rock 4. After keeping the stress state constant for 1 hour, adjust the X through the computer 1. Slowly reduce the X-direction stress and Y-direction stress to the servo actuator 11 and the Y-direction servo actuator 14, each time synchronously reducing 20MPa, with an interval of 30min, until the transparent rock 4 undergoes obvious impact rockburst damage, stop the test, During the test, the data acquisition sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com