Loop tube jet rock core oil washing instrument

A technology of jet type and oil washing instrument, applied in the field of core oil washing instrument, can solve the problems of long time, low efficiency, affecting the cleaning effect of crude oil, etc., and achieve the effect of good protection, large contact area, and improved oil washing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

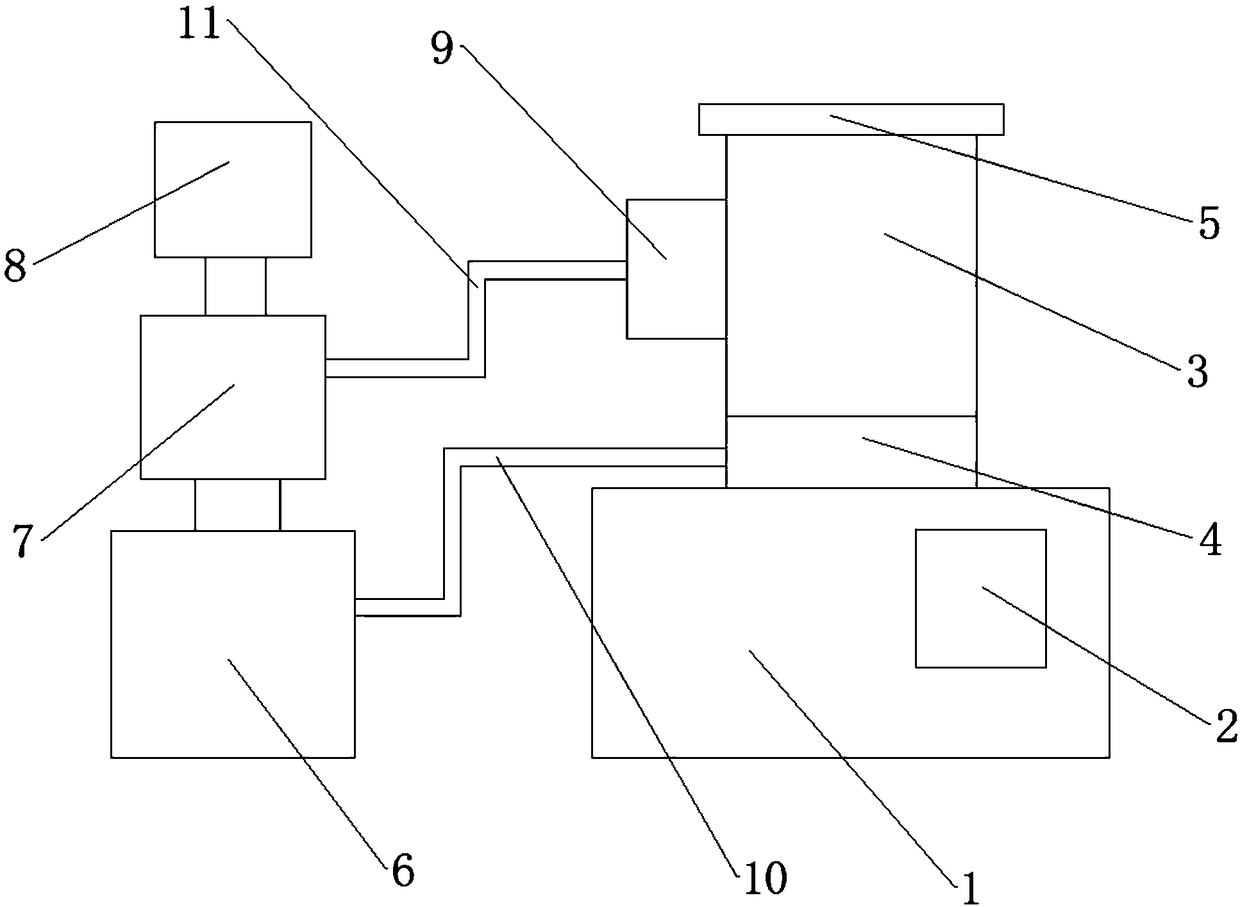

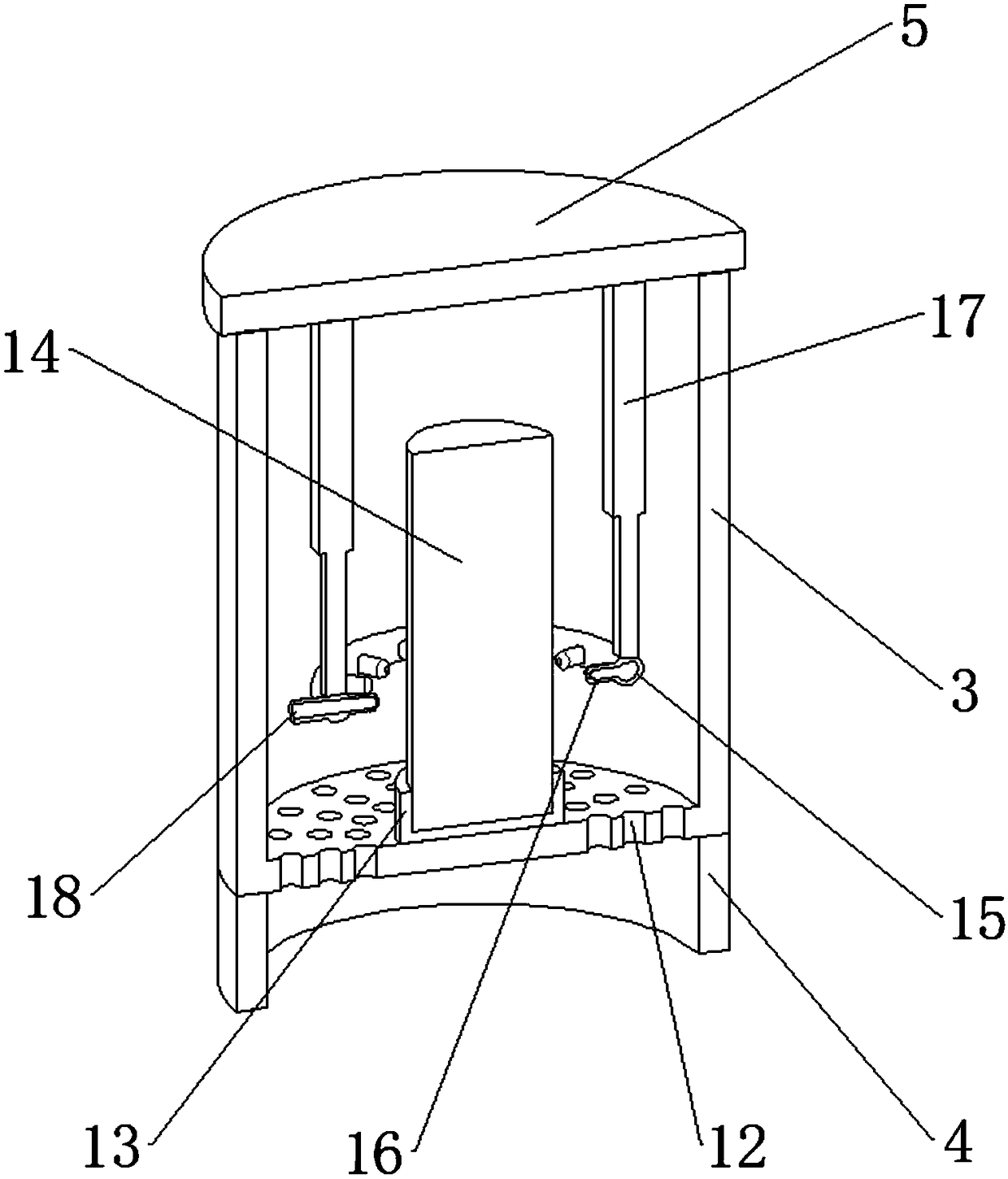

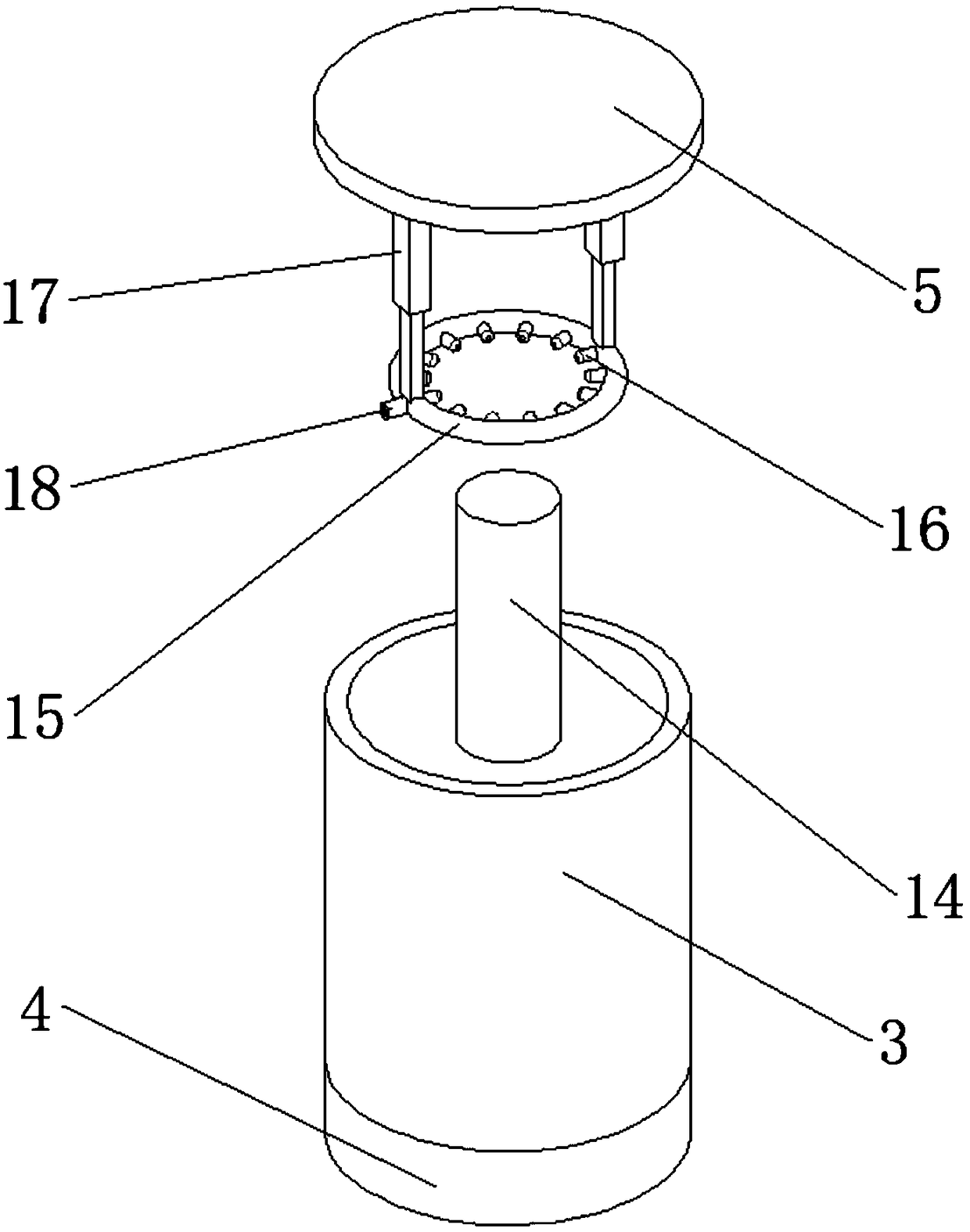

[0039] see figure 1 , a ring tube spray core oil washing instrument, including a base 1, a control panel 2 is fixedly connected to the base 1, and a micro MCU and a parameter control module are connected in the control panel 2, which can control the parameters of each component of the whole device and is easy to complete Different oil washing requirements, the upper end of the base 1 is fixedly connected with the waste liquid recovery chamber 4, the upper end of the waste liquid recovery chamber 4 is fixedly connected with the core chamber 3, the upper end of the core chamber 3 is covered with a sealing cover 5, and the sealing cover 5 is connected with the core chamber. 3 are connected with anti-claw screw rods, which are easy to fix the sealing cover 5 and ensure high sealing performance. One side of the base 1 is provided with an organic solvent chamber 6, and the upper end of the organic solvent chamber 6 is connected with a liquid collection chamber 7, and the organic solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com