Multilayer acute angle membrane type wall vibration folding high-efficiency particle heat exchanging device

A technology of heat exchange device and sharp cornea, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc. The effect of high water cycle safety, small footprint and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

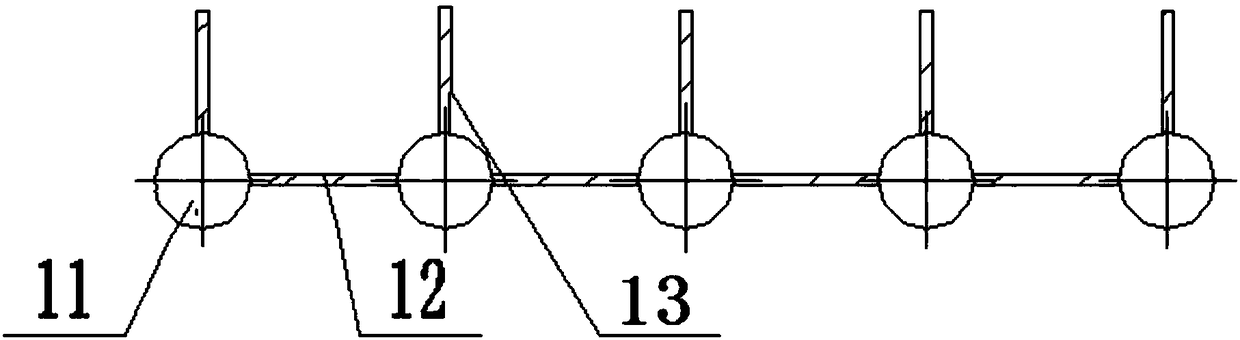

[0035] The multi-layer acute-corner wall vibration reentry high-efficiency particle heat exchange device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] as attached Figure 1~2 As shown, it includes: a base 10, a furnace body 3 located above the base 10 and a plurality of acute-corneal wall structures 4, the inner wall of the furnace body 3 is filled with heat-insulating materials, and a plurality of Vibrating spring 6 is installed with a vibrating motor 7 on the base 10, which is used to drive the body of heater 3 to vibrate on the vibrating spring 6; wherein, a feeding port is formed on the body of heater 3, and a feeding hopper 1 communicates with the feeding port. It is used to feed solid particles into the furnace body 3, and a feed valve 2 is installed on the feed port.

[0037] Each acute-corner wall structure 4 includes: a plurality of water-cooling tubes 11, which are arranged at intervals to form a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com