Application of an acute-corneal wall structure in particle heat transfer

A technology of wall structure and sharp cornea, applied in the field of high-temperature waste heat utilization of granular materials, can solve the problems of air bubbles not easily floating to the middle, large floor space, large power consumption, etc., and achieve high water circulation safety, small floor space, high power low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

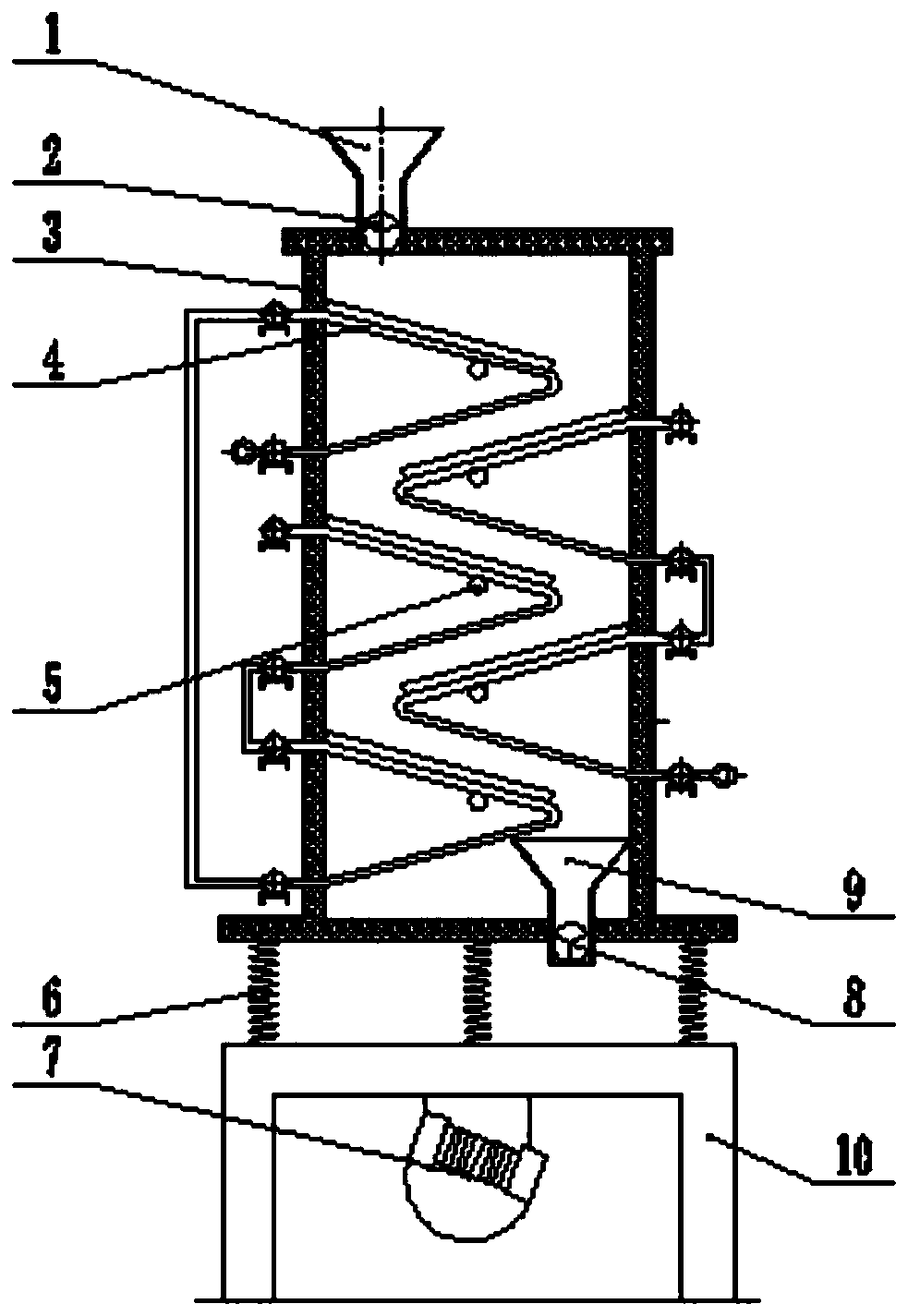

[0032] The application of the acute-corne wall structure of the present invention in particle heat exchange will be described in detail below with reference to the accompanying drawings.

[0033] as attached Figure 1~2 As shown, it includes: a base 10, a furnace body 3 located above the base 10 and a plurality of acute-corneal wall structures 4, the inner wall of the furnace body 3 is filled with heat-insulating materials, and a plurality of Vibrating spring 6 is installed with a vibrating motor 7 on the base 10, which is used to drive the body of heater 3 to vibrate on the vibrating spring 6; the vibrating motor vibrates, and the body of heater vibrates on the vibrating spring with an amplitude of 3-5mm.

[0034] Wherein, a feeding port is formed on the furnace body 3, and a feeding hopper 1 communicates with the feeding port for passing solid particles into the furnace body 3, and a feeding valve 2 is installed on the feeding port.

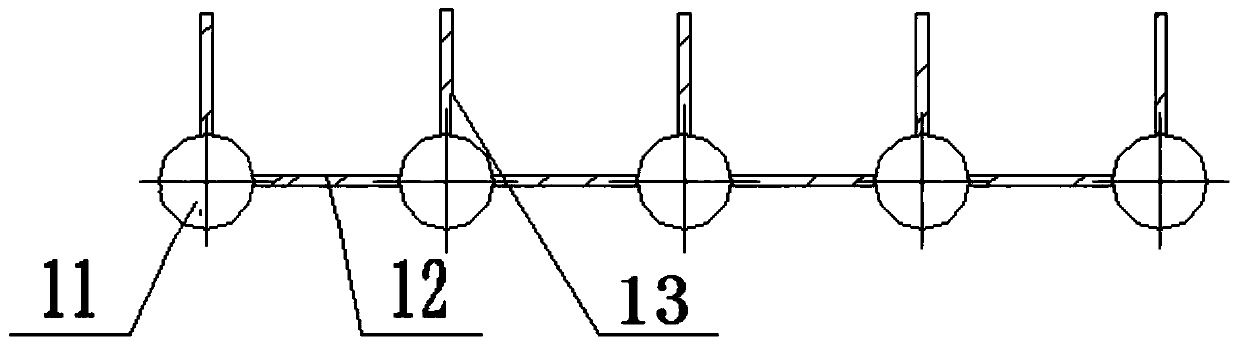

[0035] Each acute-corner wall structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com