Coupled generating system matched with steel ball milling system and used for drying sludge by using smoke

A technology for drying sludge and power generation system, which is applied in the fields of dewatering/drying/concentrating sludge treatment, steam generation, lighting and heating equipment, etc. good performance, significant social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

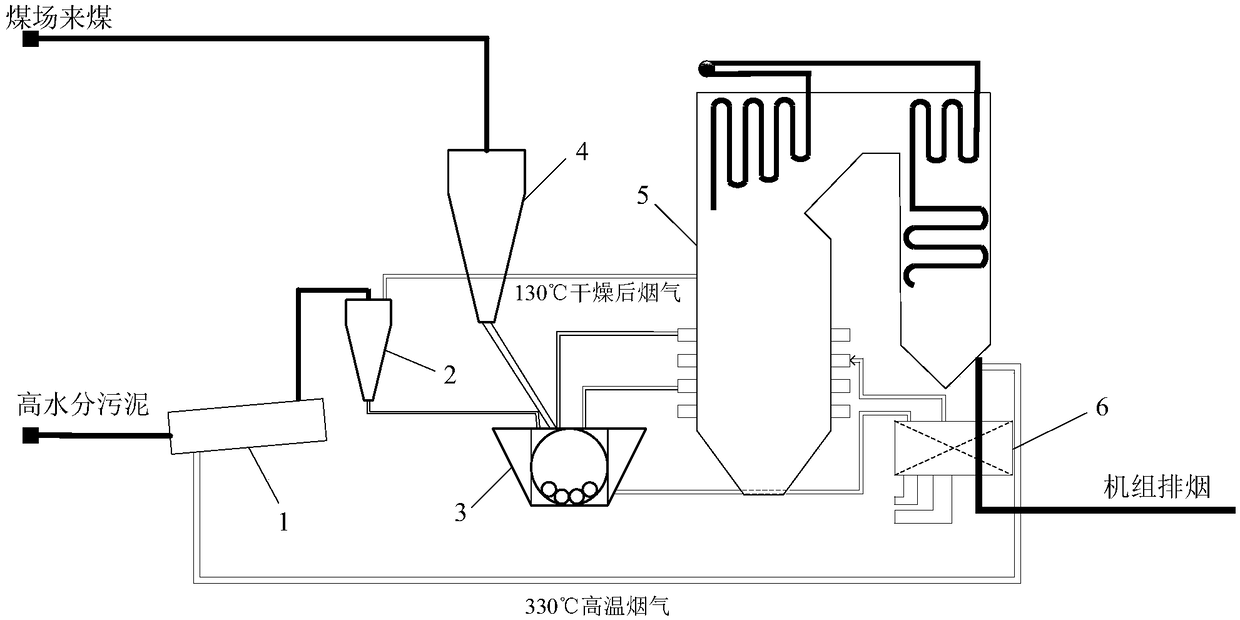

[0018] Such as figure 1 As shown, the present invention provides a steel ball mill pulverizing system and coupled power generation system using flue gas dried sludge, including a dryer 1, a dried sludge storage bin 2, a steel ball coal mill 3, a coal bunker 4, Boiler 5 and air preheater 6; Among them, dryer 1 is used to dehydrate and dry the high-moisture sludge dehydrated by the sewage treatment plant that is sent quantitatively by the sludge feed screw, and the outlet of dryer 1 is connected to the dry The inlet of the sludge storage bin 2, the outlet of the dried sludge storage bin 2 and the outlet of the coal bunker 4 are all connected to the position where steel balls are added on the top of the steel ball coal mill 3, and the outlet of the steel ball coal mill 3 is connected to the boiler 5 The high-temperature flue gas between the furnace, the boiler economizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com