A kind of black weeding non-woven fabric and its production process

A production process and non-woven technology, applied in the agricultural field, can solve the problems of soil, air pollution, non-degradability, soil erosion, etc., and achieve the effects of simple processing technology, good anti-oxidation performance, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

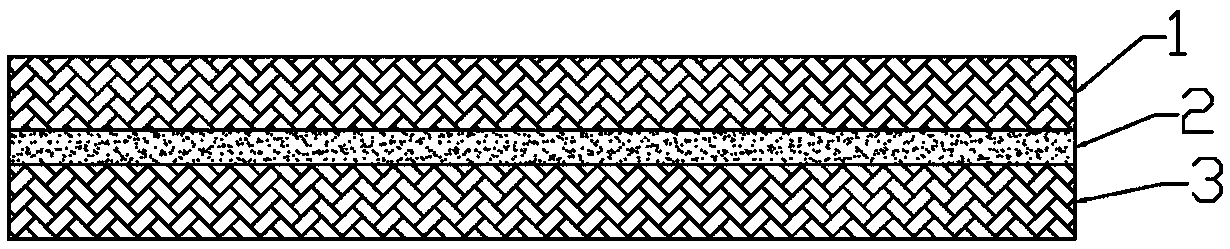

[0032] Embodiment 1: as figure 1 , figure 2 Shown, a kind of production technology of black weeding non-woven fabric comprises the steps:

[0033] (1) Suction, feed the raw material polypropylene, antioxidant, anti-ultraviolet agent, and black masterbatch into the suction machine, and feed polypropylene, antioxidant, anti-ultraviolet agent, and black masterbatch according to the weight of 1:0.02:0.015:0.02 Ratio for suction, after suction, stir evenly in the hopper at a speed of 45r / min, and stir for 20 minutes to obtain material A;

[0034] (2) Melt and extrude, send the material A in step (1) into a horizontal screw extruder for melting, the melting temperature is 160°C, and send it to the melt filter after melting for 20 minutes, pass through the metering pump and spray Extrude from a silk board to obtain B fiber filaments;

[0035] (3) Stretching, the B fiber filament obtained in step (2) is extruded by pressure, and then stretched downwards naturally by gravity, enter...

Embodiment 2

[0041] Embodiment 2: as figure 1 , figure 2 Shown, a kind of production technology of black weeding non-woven fabric comprises the steps:

[0042] (1) Suction, feed the raw material polypropylene, antioxidant KY-405, UV absorber PR020-1, and black masterbatch into the suction machine, and feed polypropylene, antioxidant KY-405, UV absorber PR020-1, The black masterbatch is sucked according to the weight ratio of 1:0.02:0.015:0.02. After sucking, stir evenly in the hopper at a speed of 45r / min. Stir for 20 minutes to obtain material A;

[0043] (2) Melt and extrude, send the material A in step (1) into a horizontal screw extruder for melting, the melting temperature is 220°C, and send it to the melt filter after melting for 25 minutes, and pass through the metering pump and sprayed Extrude from a silk board to obtain B fiber filaments;

[0044] (3) Stretching, the B fiber filament obtained in step (2) is extruded by pressure, and then stretched downwards naturally by gravit...

Embodiment 3

[0050] Embodiment 3: as figure 1 , figure 2 Shown, a kind of production technology of black weeding non-woven fabric comprises the steps:

[0051] (1) Suction, feed the raw material polypropylene, antioxidant, anti-ultraviolet agent, and black masterbatch into the suction machine, and feed polypropylene, antioxidant, anti-ultraviolet agent, and black masterbatch according to the weight of 1:0.02:0.015:0.02 Ratio for suction, after suction, stir evenly in the hopper at a speed of 45r / min, and stir for 20 minutes to obtain material A;

[0052] (2) Melt and extrude, send the material A in step (1) into a horizontal screw extruder for melting, the melting temperature is 190°C, and send it to the melt filter after melting for 23 minutes, pass through the metering pump and spray Extrude from a silk board to obtain B fiber filaments;

[0053] (3) Stretching, the B fiber filaments obtained in step (2) are extruded by pressure, and then stretched downward naturally by gravity, ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com