Preparation method for high-wear-resistance pilling resisting 4D air layer Q elastic fabric

An anti-pilling and air layer technology, which is applied in the processing of textile materials, continuous processing of textile materials, two or more different solvent-based processing materials, etc., can solve the problems of comfort and softness to be improved, wear resistance And the problem of poor anti-pilling performance, to achieve the effect of superior thermal insulation, good wearability and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

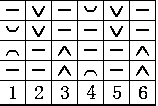

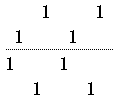

[0016] Example 1, such as figure 1 and figure 2 Shown, a kind of preparation method of high wear-resisting and anti-pilling 4D air layer Q elastic fabric, fabric comprises top layer yarn, middle yarn and bottom yarn, also comprises the following several steps, step A: choose polyester as raw material of bottom yarn, select Polyester and spandex blended as the intermediate yarn raw material, cotton yarn and spandex blended as the surface yarn raw material, and then the surface yarn, intermediate yarn and bottom yarn are woven into an air interlayer fabric blank through weaving equipment, among which, in the 6-way triangular structure , 1, 4 roads are surface yarn, the 1st road is float, tuck, tuck, float weaving structure cycle, the 4th road is tuck, float, float, tuck weaving structure cycle, 2, 5 The road is the middle yarn, the second road is looping, looping, floating thread, floating thread weaving structure cycle, the fifth road is looping, looping, floating thread, flo...

Embodiment 2

[0018] Example 2, such as figure 1 and figure 2 Shown, a kind of preparation method of high wear-resisting and anti-pilling 4D air layer Q elastic fabric, fabric comprises top layer yarn, middle yarn and bottom yarn, also comprises the following several steps, step A: choose polyester as raw material of bottom yarn, select Polyester and spandex blended as the intermediate yarn raw material, cotton yarn and spandex blended as the surface yarn raw material, and then the surface yarn, intermediate yarn and bottom yarn are woven into an air interlayer fabric blank through weaving equipment, among which, in the 6-way triangular structure , 1, 4 roads are surface yarn, the 1st road is float, tuck, tuck, float weaving structure cycle, the 4th road is tuck, float, float, tuck weaving structure cycle, 2, 5 The road is the middle yarn, the second road is looping, looping, floating thread, floating thread weaving structure cycle, the fifth road is looping, looping, floating thread, flo...

Embodiment 3

[0021] Example 3, such as figure 1 and figure 2 Shown, a kind of preparation method of high wear-resisting and anti-pilling 4D air layer Q elastic fabric, fabric comprises top layer yarn, middle yarn and bottom yarn, also comprises the following several steps, step A: choose polyester as raw material of bottom yarn, select Polyester and spandex blended as the intermediate yarn raw material, cotton yarn and spandex blended as the surface yarn raw material, and then the surface yarn, intermediate yarn and bottom yarn are woven into an air interlayer fabric blank through weaving equipment, among which, in the 6-way triangular structure , 1, 4 roads are surface yarn, the 1st road is float, tuck, tuck, float weaving structure cycle, the 4th road is tuck, float, float, tuck weaving structure cycle, 2, 5 The road is the middle yarn, the second road is looping, looping, floating thread, floating thread weaving structure cycle, the fifth road is looping, looping, floating thread, flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com