Preparation method of red phosphorus-zinc oxide heterojunction film for rapid photocatalytic sterilization

A photocatalysis, zinc oxide technology, applied in photocatalysis, semiconductor heterojunction, can solve the problems of limited activity, low charge separation efficiency, poor photocatalytic efficiency of ZnO, etc., to achieve rapid antibacterial properties, low implementation difficulty, and excellent antibacterial effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1, mechanical polishing of titanium sheet

[0040] Use 240 and 800 mesh emery on the polishing machine to polish the titanium sheet in turn until the surface is smooth, then place the polished titanium sheet in acetone, absolute ethanol and deionized water for 15 minutes, and then dry it naturally at room temperature for later use;

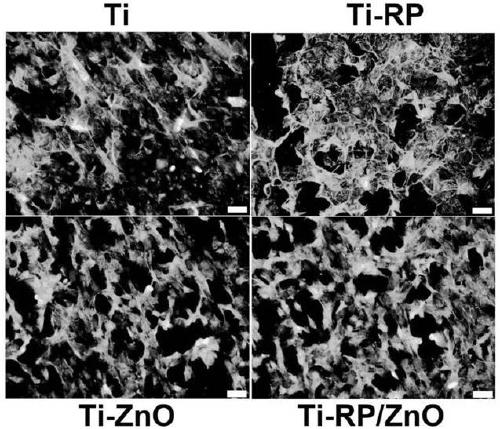

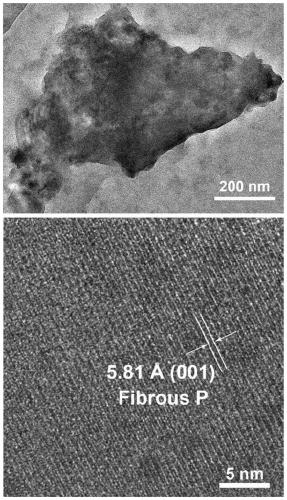

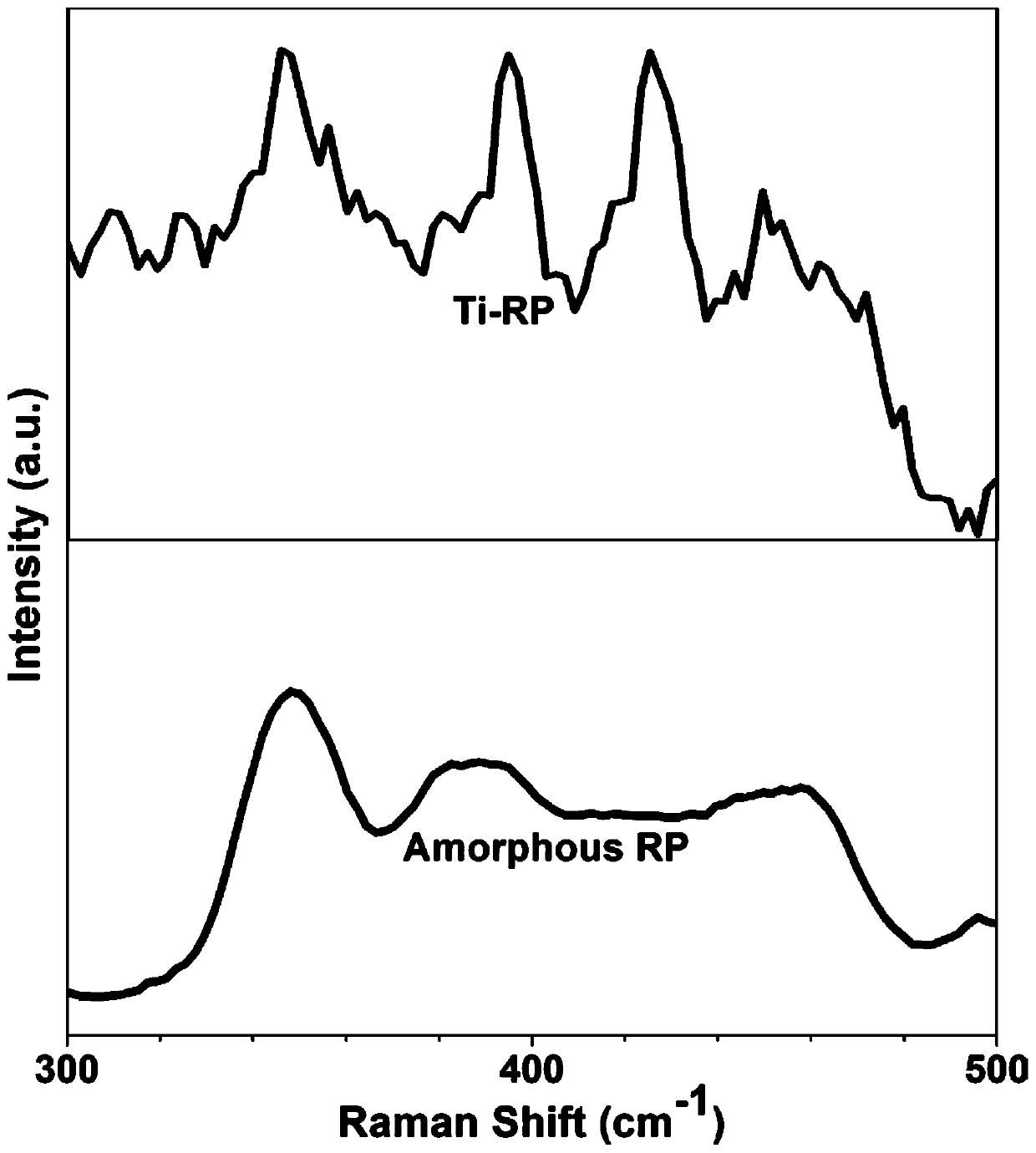

[0041] Step 2, preparation of red phosphorus film

[0042] The polished titanium sheet obtained in step 1 is used as a substrate, and a uniform red phosphorus film is plated by chemical vapor deposition (CVD). The specific steps are:

[0043] 1) Put the red phosphorus powder at 200°C, hydrothermally treat it for 12 hours, slowly lower it to room temperature, and grind it to a uniform powder below 100 microns after vacuum drying;

[0044] 2) Put the pretreated red phosphorus and titanium sheets in a CVD furnace, first pass argon gas at a rate of 2 sccm, then raise the temperature to 650 °C at a rate of 10 °C / min, and keep it for 5 hour...

Embodiment 2

[0049] Step 1: Mechanical polishing of titanium sheet

[0050] Polish the titanium sheet with 240 and 800 mesh emery on the polishing machine in turn, until the surface is smooth, then place the polished titanium sheet in acetone, absolute ethanol and deionized water for ultrasonic cleaning for 15 minutes each, and dry naturally at room temperature for use;

[0051] Step 2, Preparation of Red Phosphorus Film

[0052] The polished titanium sheet obtained in step 1 is used as a substrate, and a layer of uniform red phosphorus film is plated by chemical vapor deposition (CVD), and the specific steps are:

[0053] 1) Put the red phosphorus powder at 200 °C, hydrothermally treat it for 12 hours, slowly reduce to room temperature, and grind it to a uniform powder below 100 microns after vacuum drying;

[0054] 2) Put the pretreated red phosphorus and titanium sheets in a CVD furnace, first pass argon at a rate of 2 sccm, then heat up at a rate of 10°C / min to 650°C, and keep the tem...

Embodiment 3

[0059] Step 1: Mechanical polishing of titanium sheet

[0060] Polish the titanium sheet with 240 and 800 mesh emery on the polishing machine in turn, until the surface is smooth, then place the polished titanium sheet in acetone, absolute ethanol and deionized water for ultrasonic cleaning for 15 minutes each, and dry naturally at room temperature for use;

[0061] Step 2, Preparation of Red Phosphorus Film

[0062] The polished titanium sheet obtained in step 1 is used as a substrate, and a layer of uniform red phosphorus film is plated by chemical vapor deposition (CVD), and the specific steps are:

[0063] 1) Put the red phosphorus powder at 200 °C, hydrothermally treat it for 12 hours, slowly reduce to room temperature, and grind it to a uniform powder below 100 microns after vacuum drying;

[0064] 2) Put the pretreated red phosphorus and titanium sheets in a CVD furnace, first pass argon at a rate of 2 sccm, then heat up at a rate of 10°C / min to 650°C, and keep the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com