Annealing, cooling and packaging method and system for mosquito-repellent incense type large scattering disc

A packaging method and technology of a packaging system, applied in the field of mechanical processing, can solve the problems of uneven hardness of pipes, difficulty in shaping, single-layer packaging and transportation costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0027] According to the applicant's research, it is found that in the existing annealing and packaging process of the copper tube mosquito-repellent incense type large scattered coil tube, the coiled tube is first unloaded, and then the tube is annealed online, and the soft tube is processed at the other end. volume, please refer to figure 1 , figure 1 It is a schematic flow chart of an existing on-line annealing technology for pipes provided by the first embodiment of the present invention. The on-line annealing process anneals each part of a single pipe in turn, and the annealing efficiency is low. It is rapid and instantaneous heating, and the cooling time is short, resulting in uneven hardness of the copper pipe that cannot meet the use requirements of the copper pipe. Small, the tube cannot be squeezed during packaging, and can only be packaged and transported in a single layer, which increases the transportation cost. The nitrogen filling time is limited by the online ...

no. 2 example

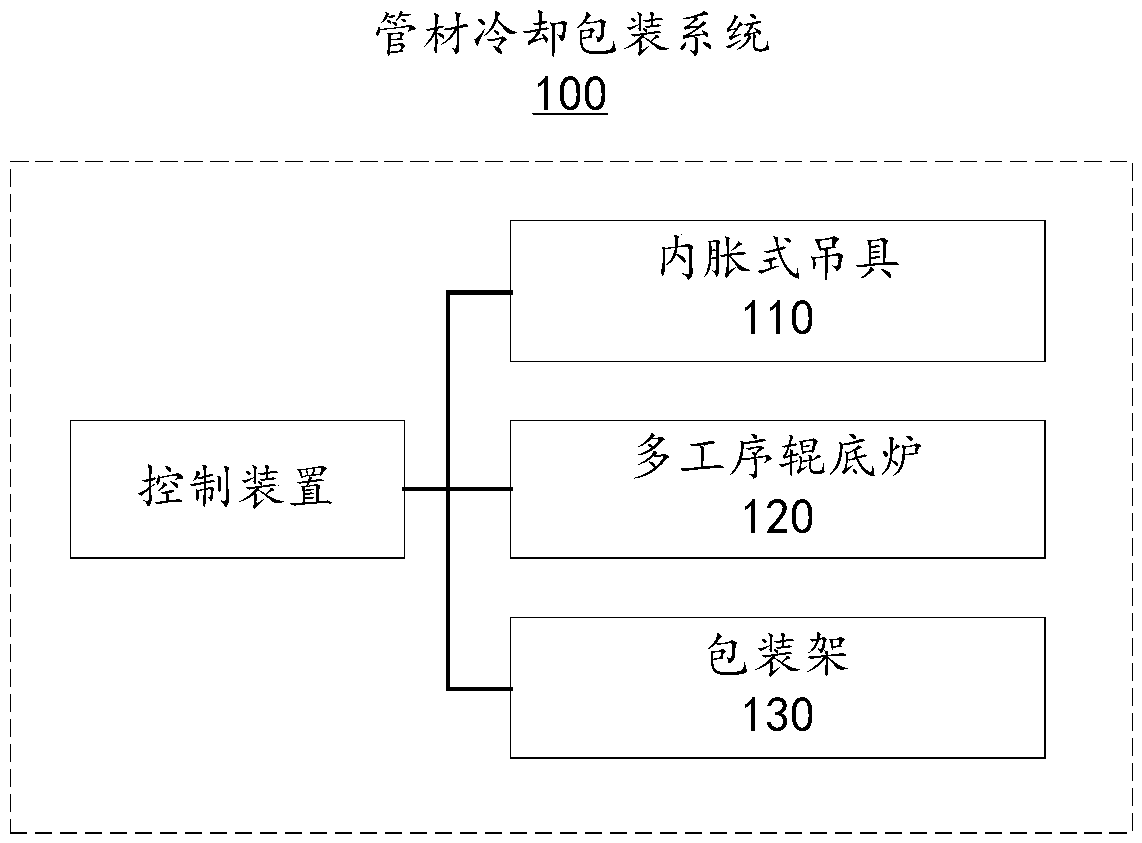

[0045] In order to cooperate with the annealing, cooling and packaging method of the mosquito-repellent-repellent incense large discs provided in the first embodiment of the present invention, the second embodiment of the present invention also provides an annealing, cooling and packaging system 100 of the mosquito-repellent-repellent incense large discs.

[0046] Please refer to image 3 , image 3 It is a block diagram of a mosquito-repellent-repellent incense-type large disc annealing, cooling and packaging system provided by the second embodiment of the present invention.

[0047] Annealing, cooling and packaging system 100 of mosquito-repellent incense large discs includes internal expansion spreader 110 , multi-process roller hearth furnace 120 and packaging rack 130 .

[0048] The internal expansion spreader 110 is used to place the first large plate formed by winding the formed pipe into the multi-process roller hearth furnace or pit annealing furnace, and is also use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com