A kind of binder for lithium ion battery separator coating and preparation method

A lithium-ion battery and binder technology, applied in the direction of adhesive types, battery pack components, nitrile copolymer adhesives, etc., can solve the problems of high moisture content and poor heat resistance of the coating, and achieve conduction The effect of improving performance, improving heat resistance and good industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

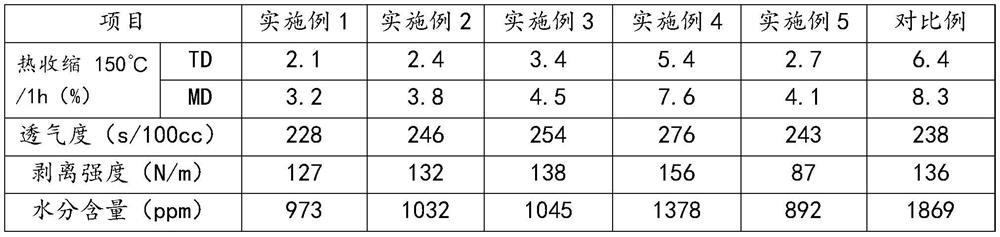

Embodiment 1

[0033] The binder for lithium-ion battery diaphragm coating of the present embodiment comprises the following raw materials in weight percentage: 33% of acrylonitrile, 30% of acrylic acid, 3% of butyl acrylate, 1.5% of ammonium persulfate, 1.5% of lithium hydroxide, ten Sodium dialkylbenzene sulfonate 2%, p-nonylphenol polyoxyethylene ether 1%, water 51%; the above raw materials are of analytical grade and above.

[0034] Preparation:

[0035] Add 20% ultrapure water to the buffer tank, then add the initiator, stir evenly to prepare an aqueous solution of the initiator;

[0036] Add all the monomers, emulsifiers and the remaining 80% ultrapure water into the emulsification tank, stir at high speed for emulsification, and obtain a pre-emulsion;

[0037] Add 30% pre-emulsion in the reaction kettle, stir and raise the temperature, control the temperature at 75°C, add 30% initiator and lithium hydroxide aqueous solution, and react for 2 hours;

[0038] Slowly add the remaining p...

Embodiment 2

[0040] The binder for the lithium-ion battery separator coating of the present embodiment comprises the following raw materials in weight percentage: 26% of acrylonitrile, 25% of acrylic acid, 3% of 2-ethylhexyl acrylate, 1.5% of ammonium persulfate, and Lithium 0.5%, sodium dodecylbenzene sulfonate 2%, p-nonylphenol polyoxyethylene ether 1%, water 51%; the above raw materials are of analytical grade and above.

[0041] Preparation:

[0042] Add 20% ultrapure water to the buffer tank, then add the initiator, stir evenly to prepare an aqueous solution of the initiator;

[0043] Add all the monomers, emulsifiers and the remaining 80% ultrapure water into the emulsification tank, stir at high speed for emulsification, and obtain a pre-emulsion;

[0044] Add 30% pre-emulsion in the reaction kettle, stir and raise the temperature, control the temperature at 75°C, add 30% initiator and lithium carbonate aqueous solution, and react for 2 hours;

[0045] Slowly add the remaining pre...

Embodiment 3

[0047] The binder for lithium-ion battery diaphragm coating of the present embodiment comprises the following raw materials in weight percentage: 18% of acrylonitrile, 22% of acrylic acid, 6% of isooctyl acrylate, 1.5% of ammonium persulfate, 3.5% of lithium hydroxide, Sodium dodecylbenzene sulfonate 2%, p-nonylphenol polyoxyethylene ether 1%, water 51%; the above raw materials are of analytical grade and above.

[0048] Preparation:

[0049] Add 20% ultrapure water to the buffer tank, then add the initiator, stir evenly to prepare an aqueous solution of the initiator;

[0050] Add all the monomers, emulsifiers and the remaining 80% ultrapure water into the emulsification tank, stir at high speed for emulsification, and obtain a pre-emulsion;

[0051] Add 30% pre-emulsion to the reaction kettle, stir and raise the temperature, control the temperature at 75°C, add 30% initiator and lithium sulfide aqueous solution, and react for 2 hours;

[0052] Slowly add the remaining pre-em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com